Bridge pile foundation rotary excavating drilling rig cutting type whole guard barrel follow-up pile forming construction method and system

A technology of rotary drilling rig and construction method, which is applied in the direction of rotary drilling, rotary drilling rig, drilling equipment and methods, etc., which can solve the problems of difficulty in forming holes in pile foundations, low construction efficiency, and inability to construct, and achieve economic benefits Substantial, low construction cost and fast turnaround results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

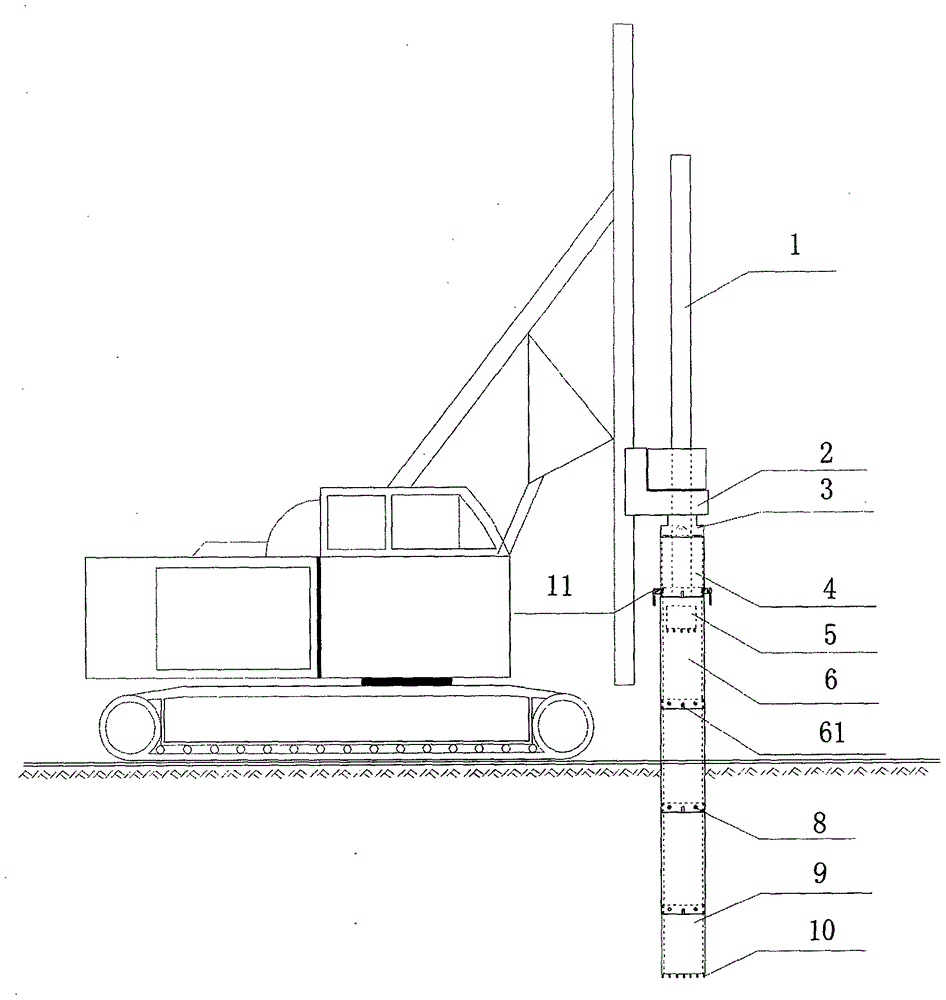

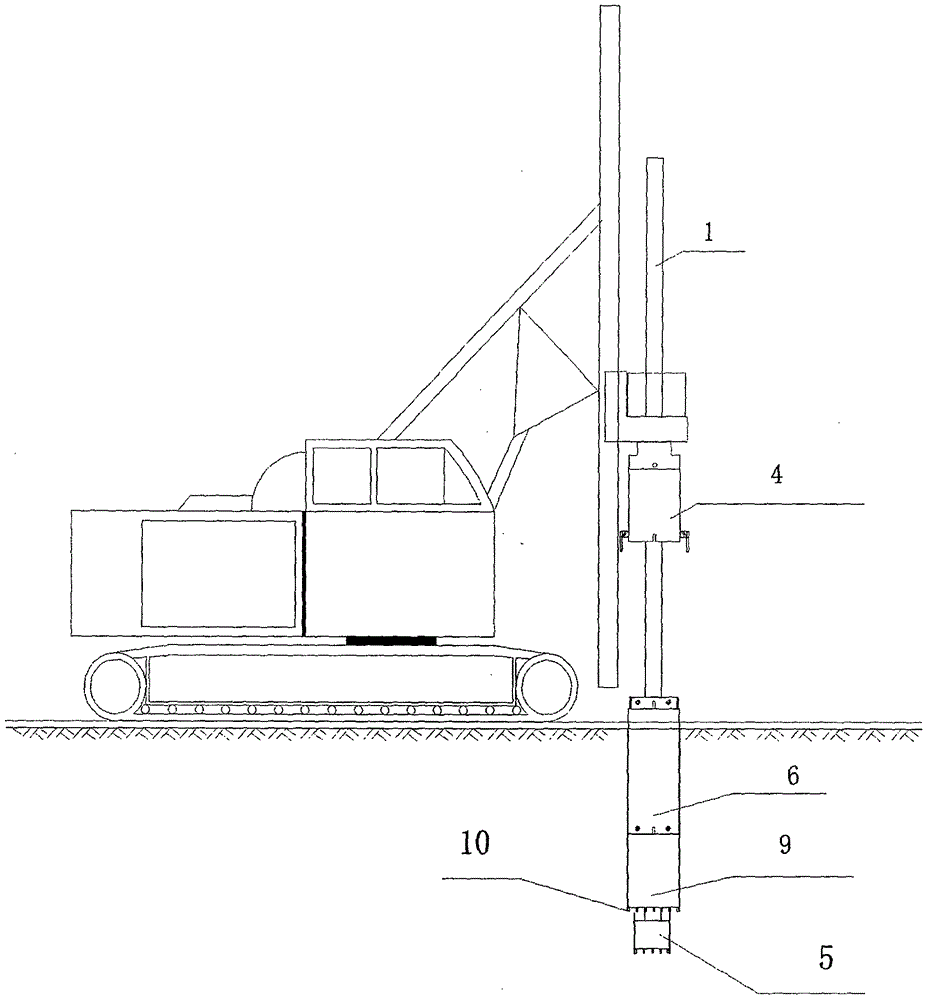

[0048] like Figure 1-10 As shown, the bridge pile foundation rotary drilling rig cutting type full casing follow-up pile construction method provided in this embodiment includes the following steps:

[0049] S1. The site is level;

[0050] S2. After the rotary drilling rig is in place, process and manufacture the cutting casing system;

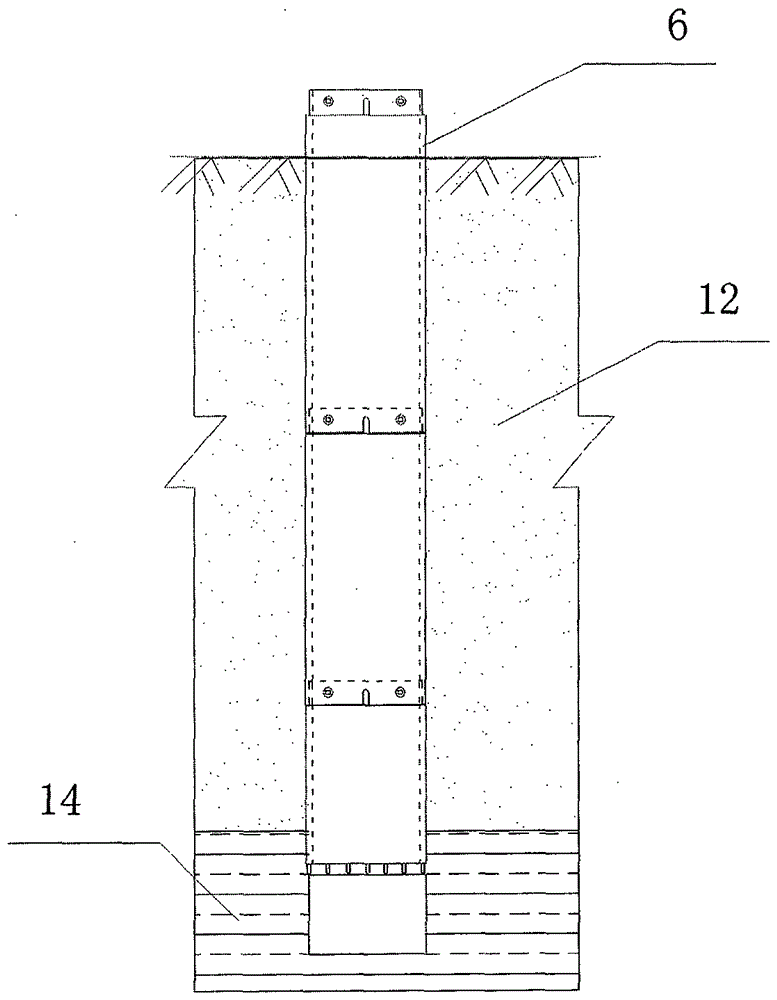

[0051] The cutting type casing system includes a power connector 3, a casing connector 4, a standard section casing 6, a cutting type bottom section casing 9 and an alloy cutting tool 10;

[0052] S3. Install the power connector 3 and the casing connector 4 on the rotary drilling rig in sequence; the upper end of the power connector 3 is connected to the rotary drilling head 2 of the rotary drilling rig, and the lower end is connected to the casing connector 4 ; Install the rotary drilling bucket 5 on the drill rod 1 of the rotary drilling rig;

[0053] Preferably, four symmetrical power connector support columns and four power connector p...

Embodiment 2

[0078] A bridge pile foundation rotary drilling rig cutting type full casing follow-up pile construction system is used to implement the bridge pile foundation rotary drilling rig cutting type full casing follow-up pile construction method described in Embodiment 1. The system includes a rotary drilling rig and a cutting casing system; the specific structure of the rotary drilling rig can be the same as that of the existing machine, and the cutting casing system includes a power connector 3, a casing connector 4, a standard section casing 6, The cutting bottom section casing 9 and the alloy cutting tool 10; as for the specific connection relationship of these structures, the technical features and corresponding parameters have been described in detail above, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com