Round aluminum alloy pipe concrete compound column

An aluminum alloy tube and concrete technology, applied in columns, piers, pillars, etc., can solve the problems of poor bearing capacity and ductility, large amount of steel used for section steel columns, multiple welding processes, etc., to achieve good corrosion resistance, structural The effect of reducing self-weight and reducing the self-weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

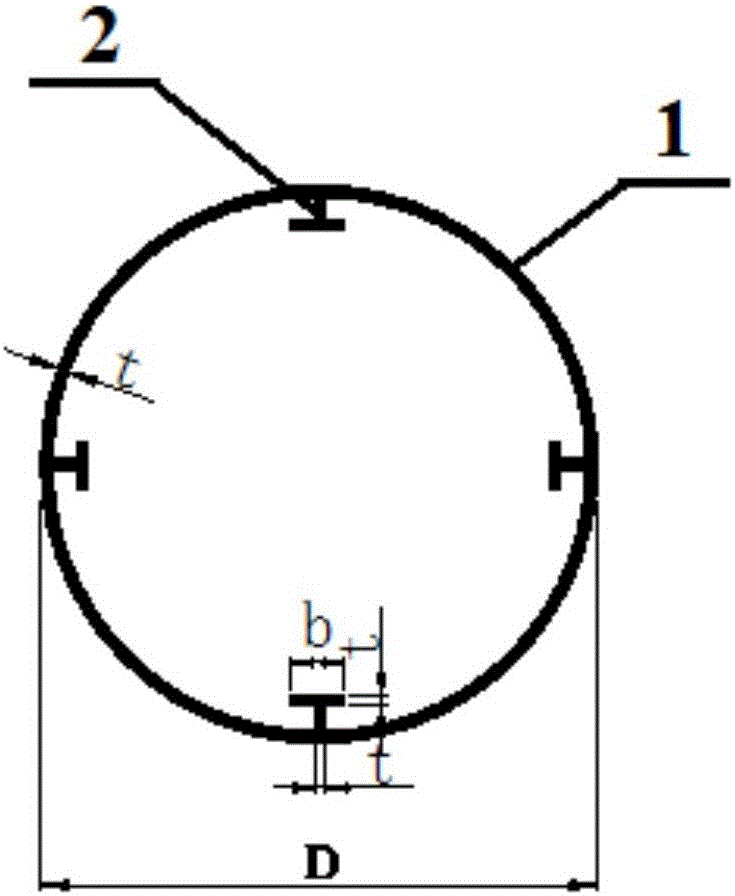

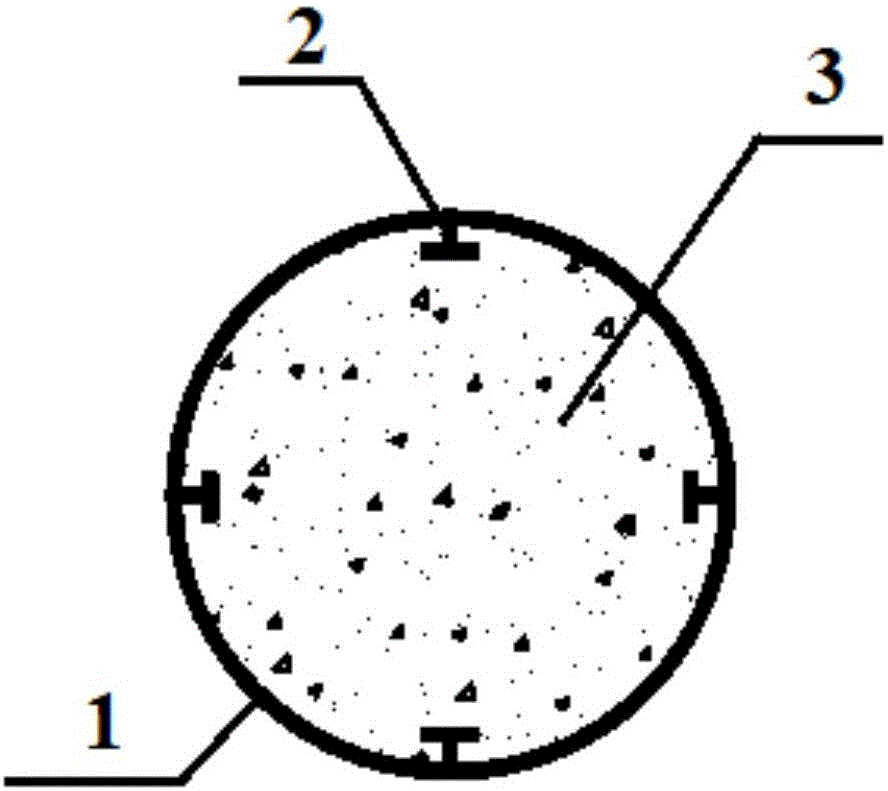

[0022] The pedestrian bridge pier is constructed by using the composite column of the invention. The pier is 6 meters high and uses double-column pier. The round alloy aluminum tube is made of 6-series high-strength aluminum alloy. The material conditional yield strength is 240MPa, and the elastic modulus is 70GPa. The specific implementation steps are as follows:

[0023] 1) According to the pier height and bridge span, the diameter D of the pipe body 1 is initially determined; the value is taken according to the relevant load design specifications, and the structural design load and the most unfavorable internal force combination value are calculated; the wall thickness t of the aluminum alloy pipe body 1 is determined according to the design load According to the structural requirements, the thickness t and width b of the connecting piece 2 are determined. The thickness t of the connecting piece 2 is equal to the wall thickness t of the pipe body 1, and the width b is equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com