Metal roof deformation joint connection structure and installation method therefor

A metal roof and deformation joint technology, which is applied in the direction of roof, building structure, roof covering, etc., can solve the problems of insufficient thermal insulation and energy saving performance, easy leakage of metal roof deformation joints, etc., to achieve reliable building airtight performance and save construction Step-by-step process, the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

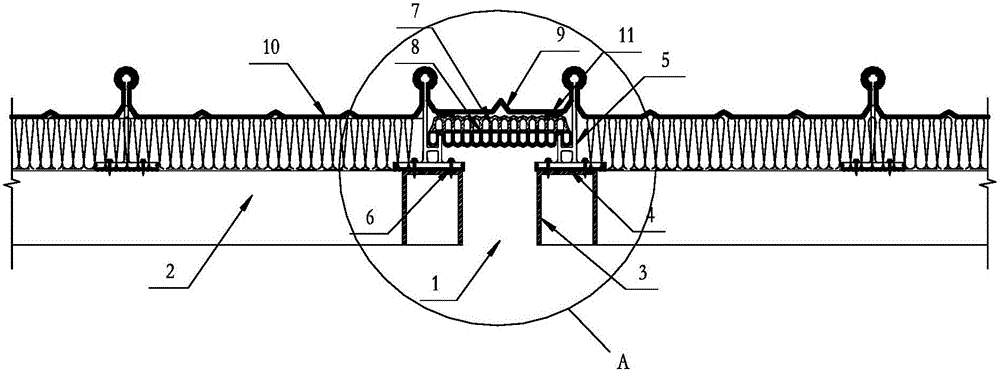

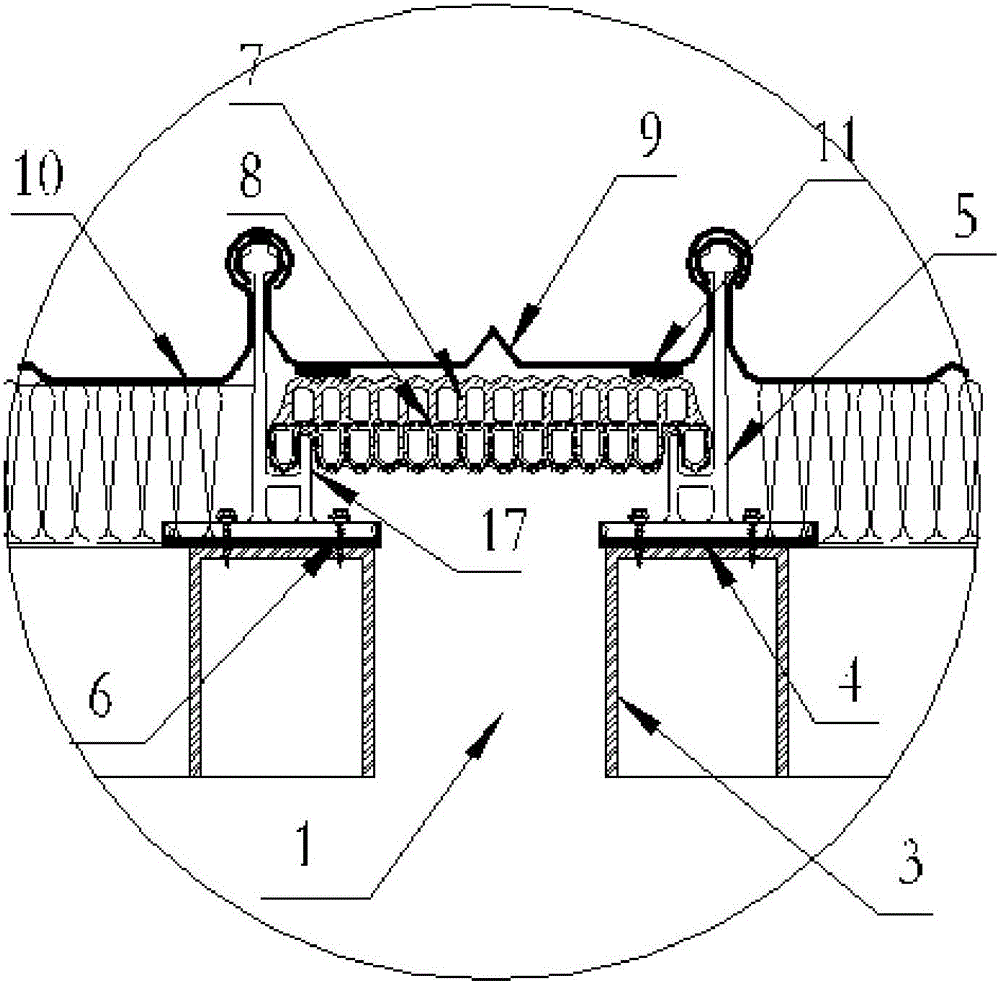

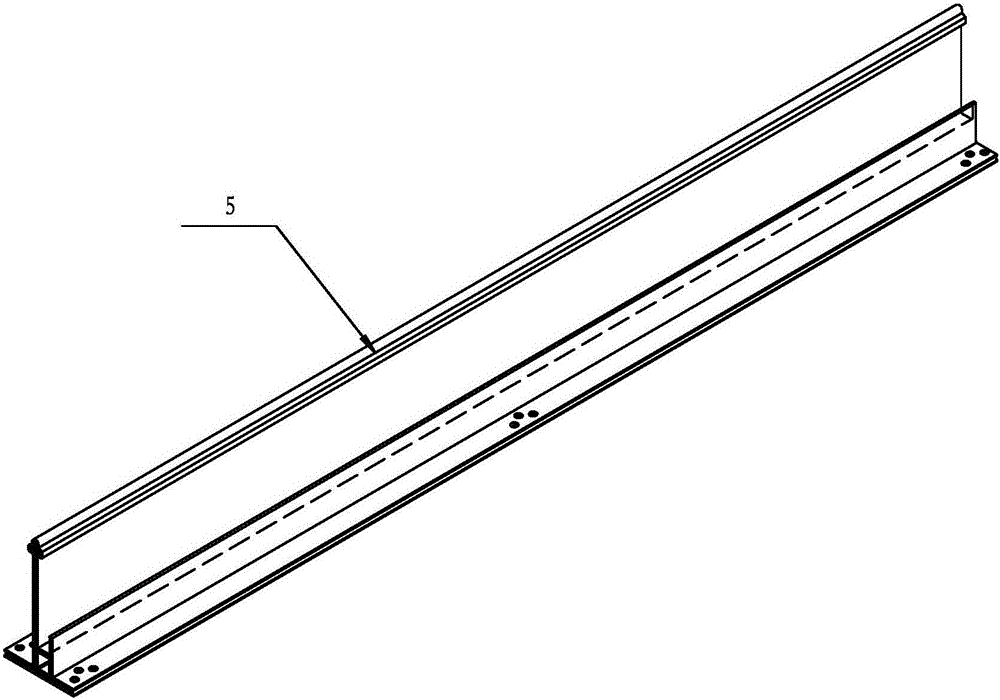

[0043] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 The connection structure of the metal roof deformation joint shown in , is provided with a standing seam metal roof panel 10 on the metal roof surface, and on both sides of the deformation joint 1 of the roof structure, there are deformation joint edge purlins vertically and fixedly connected with the main purlin 2 of the steel structure 3. The top surface of the roof structure deformation joint 1 is provided with a roof deformation joint cover plate 9, and the top surface of the deformation joint edge banding purlin 3 is fixed with an upright seam metal roof deformation seam end support 5, and the vertical seam seams arranged in parallel The end support 5 of the metal roof deformation seam connects a plurality of standing seam metal roof panels 10 and the roof deformation seam cover plates 9 sequentially by seaming. Such as figure 1 , the standing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com