A siphon power generation system

A power generation system, siphon technology, applied in siphon pipes, hydropower, non-volume pumps, etc., can solve the problems of large project investment, long construction period, and high requirements for natural conditions, and achieve cost savings and reduce natural conditions. , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

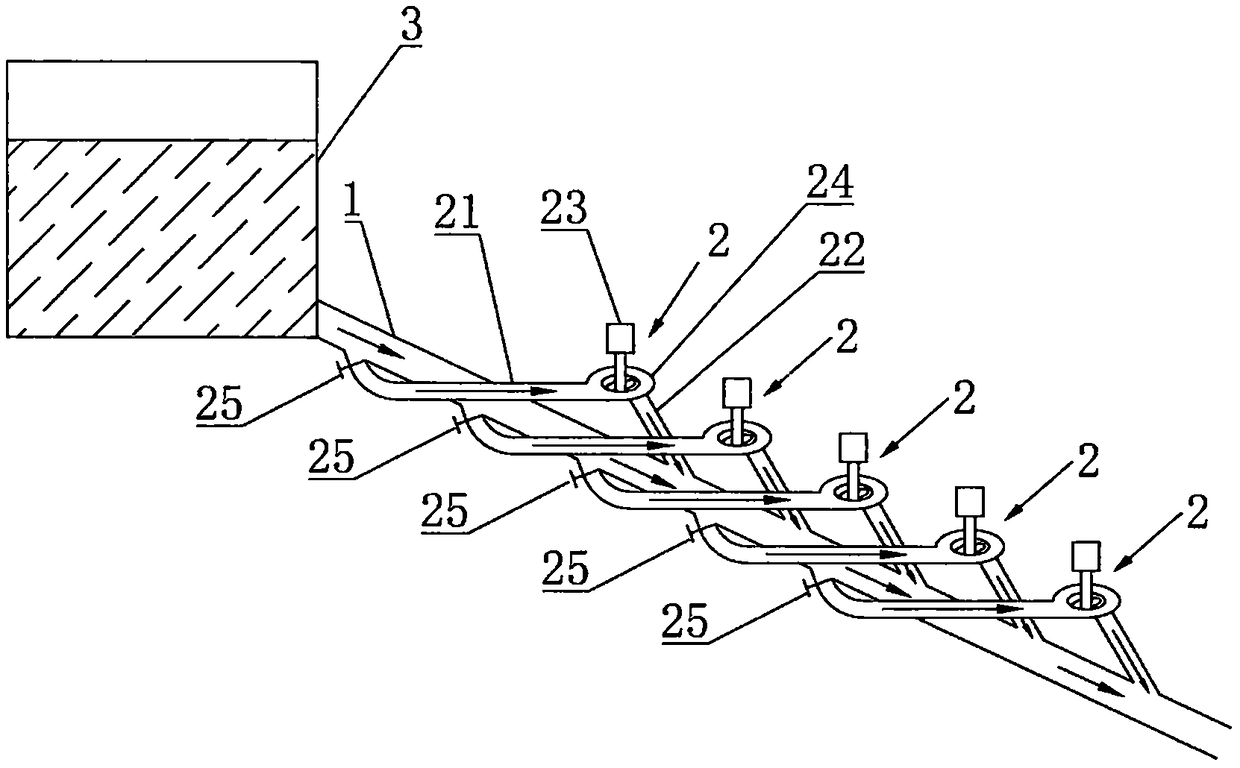

[0029] like figure 1 As shown, the siphon power generation system provided by Embodiment 1 of the present invention includes a main pipe 1 and a siphon power generation device 2, and the siphon power generation device 2 includes a branch pipe 21, a siphon pipe 22, a water turbine 24 and a generator 23, wherein the branch pipe 21 The water inlet of the siphon pipe 22 is connected with the main pipe 1, and the water outlet is connected with the water turbine 24; Downstream of the joint of the pipe 1, a water turbine 24 is connected with a generator 23 for driving the generator to generate electricity.

[0030] During use, according to the siphon principle, a vacuum is formed in the siphon tube 22 (the so-called vacuum here is relative to the atmospheric pressure, as long as it is lower than the atmospheric pressure, it can form a suction force on the water flow), and the pressure difference is used to make the water flow into the water turbine 24, like figure 1 As shown by the...

Embodiment 2

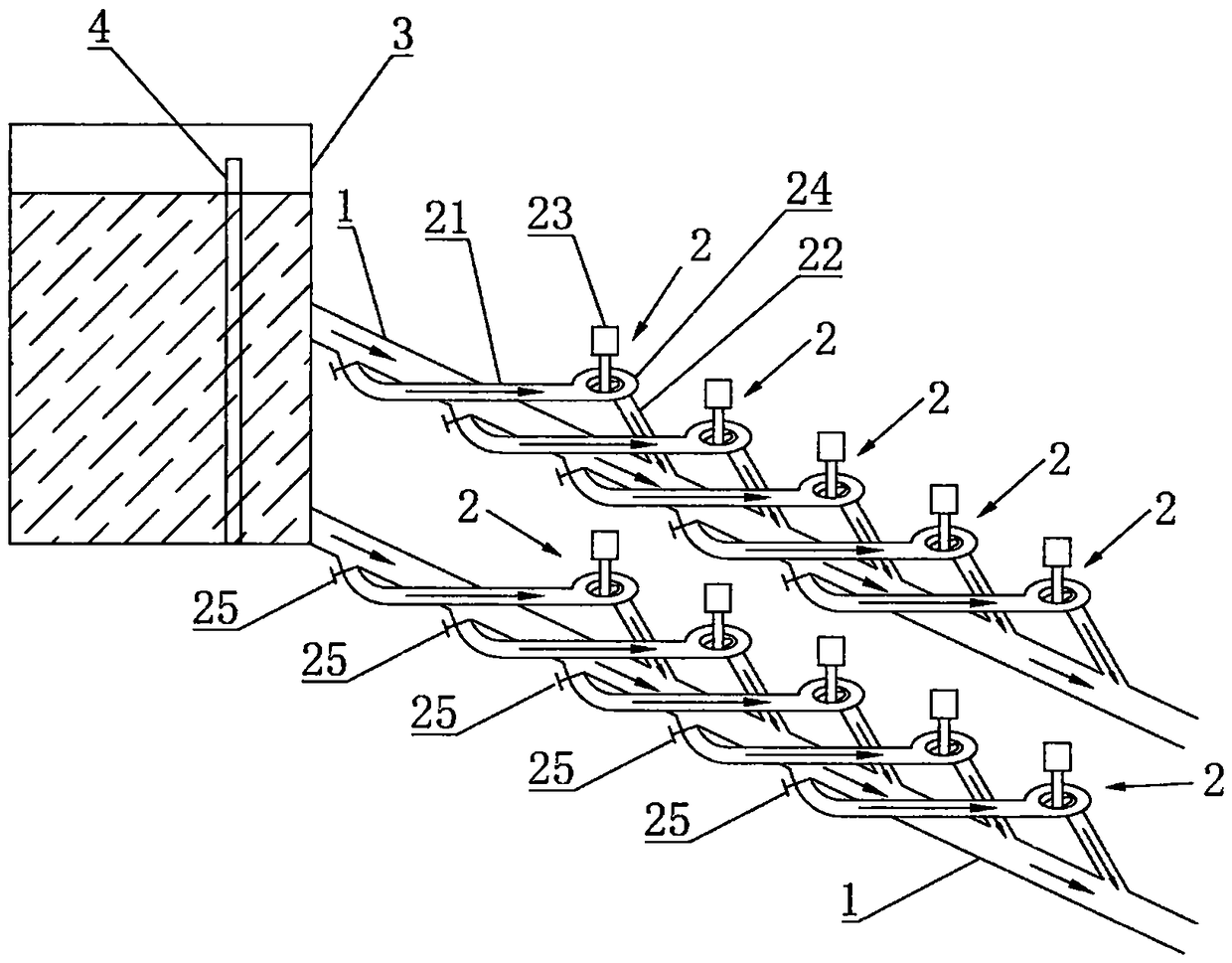

[0042] like figure 2 As shown, the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that a plurality of main flow pipes 1 are arranged in the siphon power generation system, and the upper end of each main flow pipe 1 is connected to a water source. And distributed at different water levels of the water source, each main pipe 1 is provided with a plurality of siphon power generation devices 2 in the above-mentioned embodiments at intervals, and when the water source is sufficient, the water energy can be fully utilized to increase the power generation. The generators 23 in the power generating device 2 are all connected in series, and the generated electric power is incorporated into the grid.

[0043] Furthermore, in the case of insufficient water source, in order to ensure that at least some generators can work normally and stably, such as figure 2 As shown, a water level monitor 4 is set in the w...

Embodiment 3

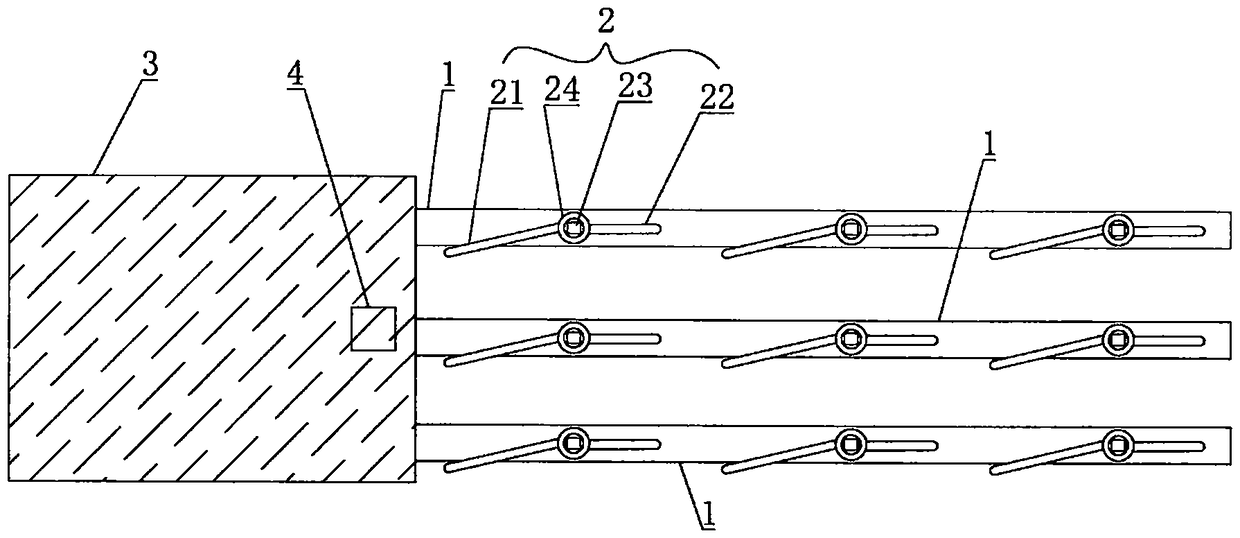

[0045] like image 3 and Figure 4 As shown, the third embodiment is basically the same as the second embodiment, and the similarities will not be repeated. The difference is that the upper ends of the plurality of mainstream pipes are located at the same water level of the water source, that is, they are all distributed at the same water level in the water source. And through the water level monitor 4 and the second water control valve to control the water flow of the corresponding main pipe 1, to ensure that the siphon power generation device 2 provided on the other main pipe 1 can obtain sufficient water flow and perform normal power generation work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com