CNG conveying hose for gas filling/gas discharge pillar of gas station

A technology for conveying hoses and gas filling stations, which is applied in the field of improving the structure of CNG conveying hoses, which can solve problems such as the decline in permeation resistance, and achieve the effect of solving electrical conductivity and barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

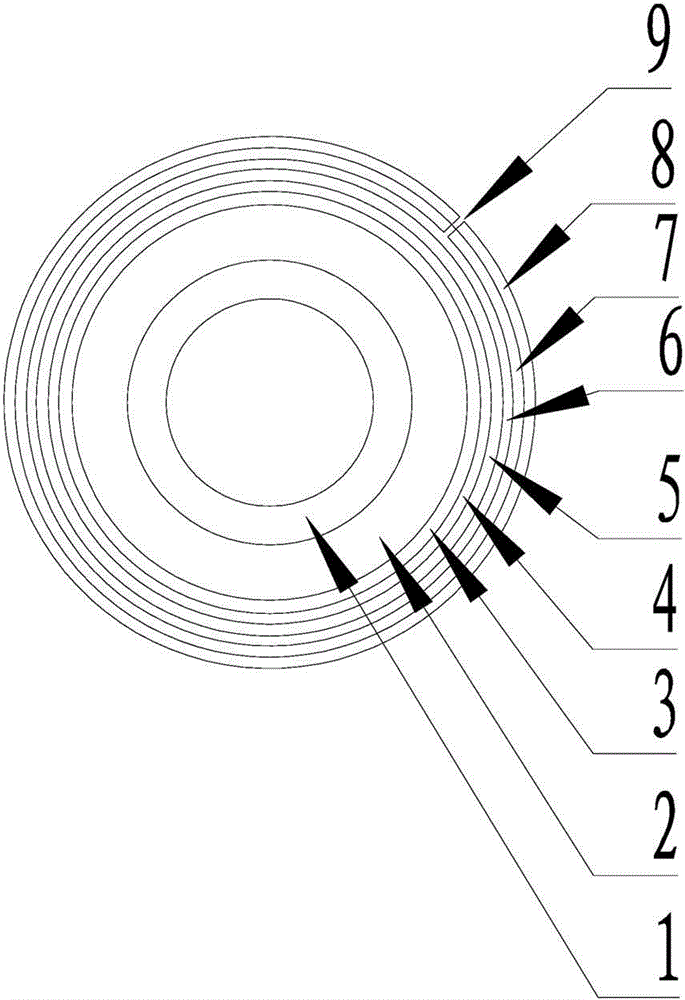

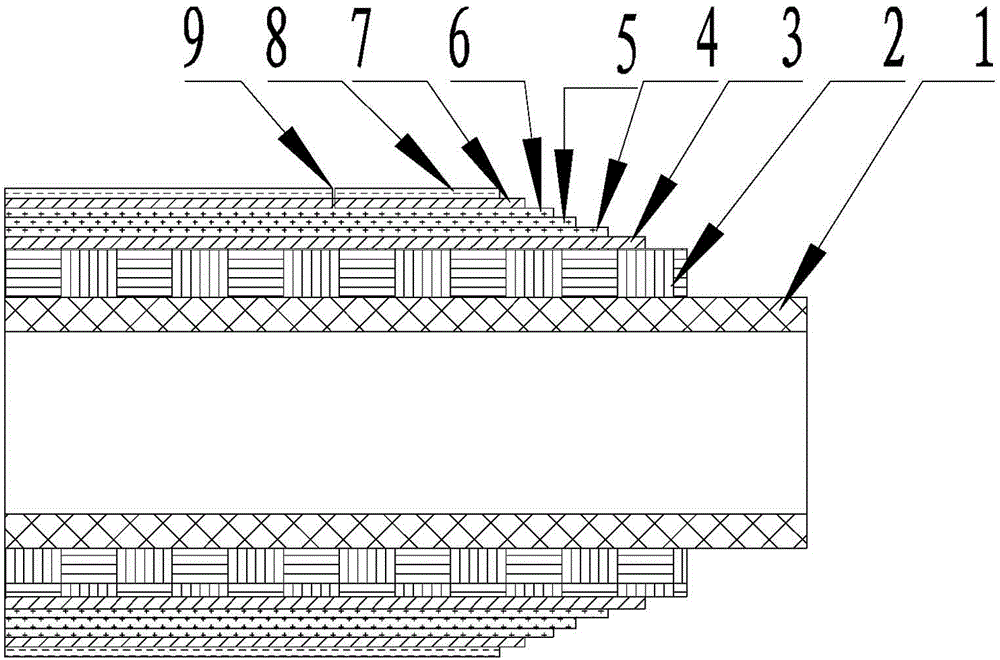

[0021] The present invention includes a medium-resistant conductive layer 1, which is characterized in that: the medium-resistant conductive layer 1 is sequentially provided with a medium-resistant anti-penetration strong layer 2, an adhesive layer 3, a braided reinforcing layer, a fast conductive layer 7 and an outer layer from the inside to the outside. protective layer 8; the end of the fast conductive layer 7 is connected to the end of the dielectric-resistant conductive layer 1; the outer protective layer is lined with micro-holes.

[0022] As a preferred solution of the present invention, the medium-resistant conductive layer 1 is nylon PA11 or PA12 conductive material; the medium-resistant and anti-penetration strength layer 2 is nylon PA11 or PA12.

[0023] As another preferred solution of the present invention, the fiber braided reinforcing layer includes a first fiber layer 4, a second fiber layer 5 and a third fiber layer 6, and the material is aramid fiber, carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap