Cigarette production automatic counter based on single chip microcomputer

A single-chip microcomputer and counter technology, applied in the field of counters, can solve problems such as hindering system production capacity, difficulty in ensuring accuracy, and low work efficiency, and achieve the effects of easy popularization and use, accurate and reliable counting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

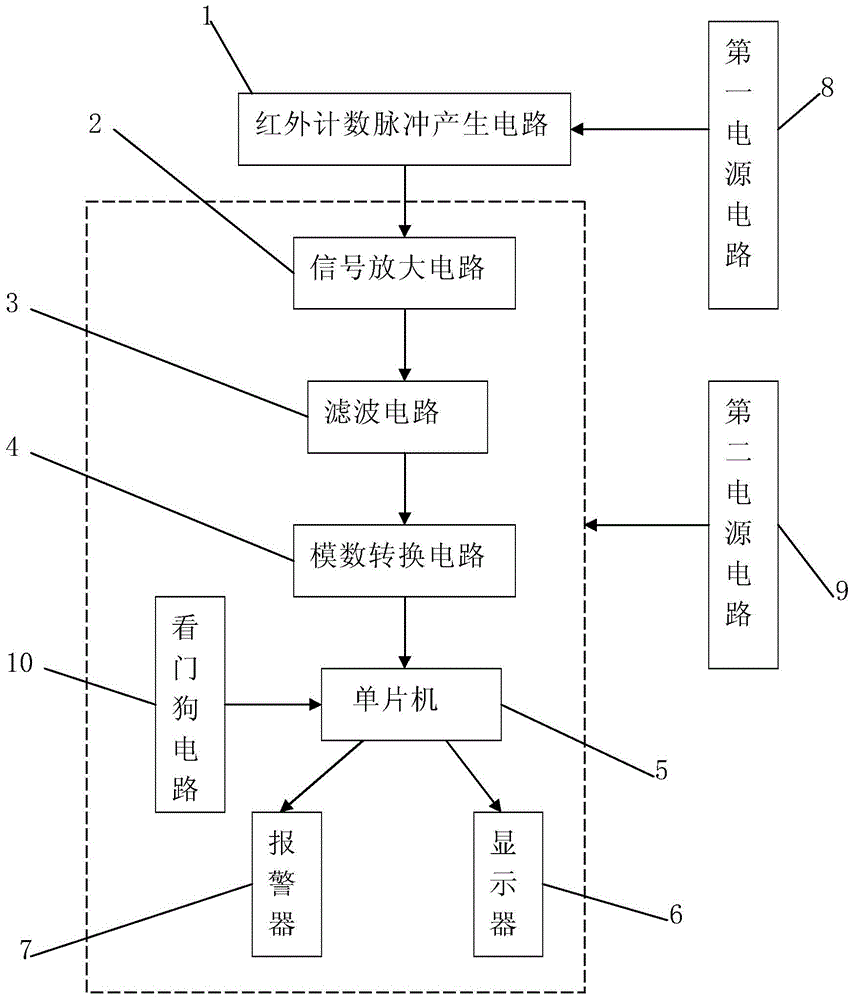

[0022] Such as figure 1 The shown automatic counter for cigarette production based on a single-chip microcomputer includes a reflective infrared count pulse generation circuit 1 for sending infrared count pulses to each cigarette on the cigarette conveyor belt, and a reflective infrared count pulse generation circuit 1 for receiving said reflective infrared count pulses. A signal amplification circuit 2 for outputting a signal from the circuit 1 and performing amplification processing, a filter circuit 3 for receiving the output signal of the signal amplification circuit 2 and performing filtering processing, and an analogue circuit for converting the output signal of the filter circuit 3 into a digital signal Digital conversion circuit 4, and the single-chip microcomputer 5 that is used to receive described analog-to-digital conversion circuit 4 output digital signals and counts, the output end of described reflective infrared counting pulse generation circuit 1 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com