A Regeneration Method of Cavity Surface of Edge-emitting Semiconductor Laser

A laser and semiconductor technology, applied in the field of semiconductors, can solve the problems of laser life loss, cavity surface burnout, band gap shrinkage and photon absorption, etc., and achieve the effect of restoring working performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

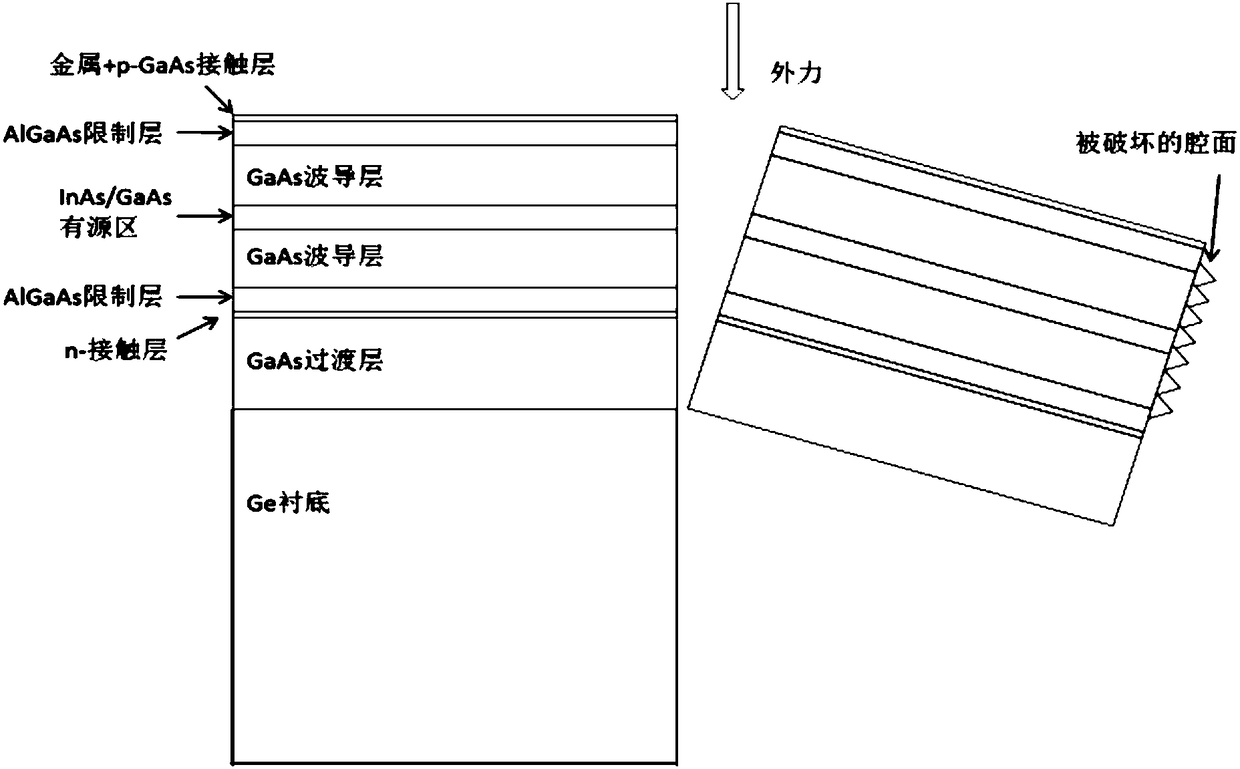

[0023] Cavity surface regeneration of Ge-based InAs / GaAs quantum dot edge-emitting lasers:

[0024] ①First, place the packaged laser on a heating platform with a temperature of 180°C, remove the wire immediately after the indium melts, and remove the laser from the heat sink. This process should always be carried out on the heating platform , and avoid the molten indium solution from sticking to the cavity surface of the laser.

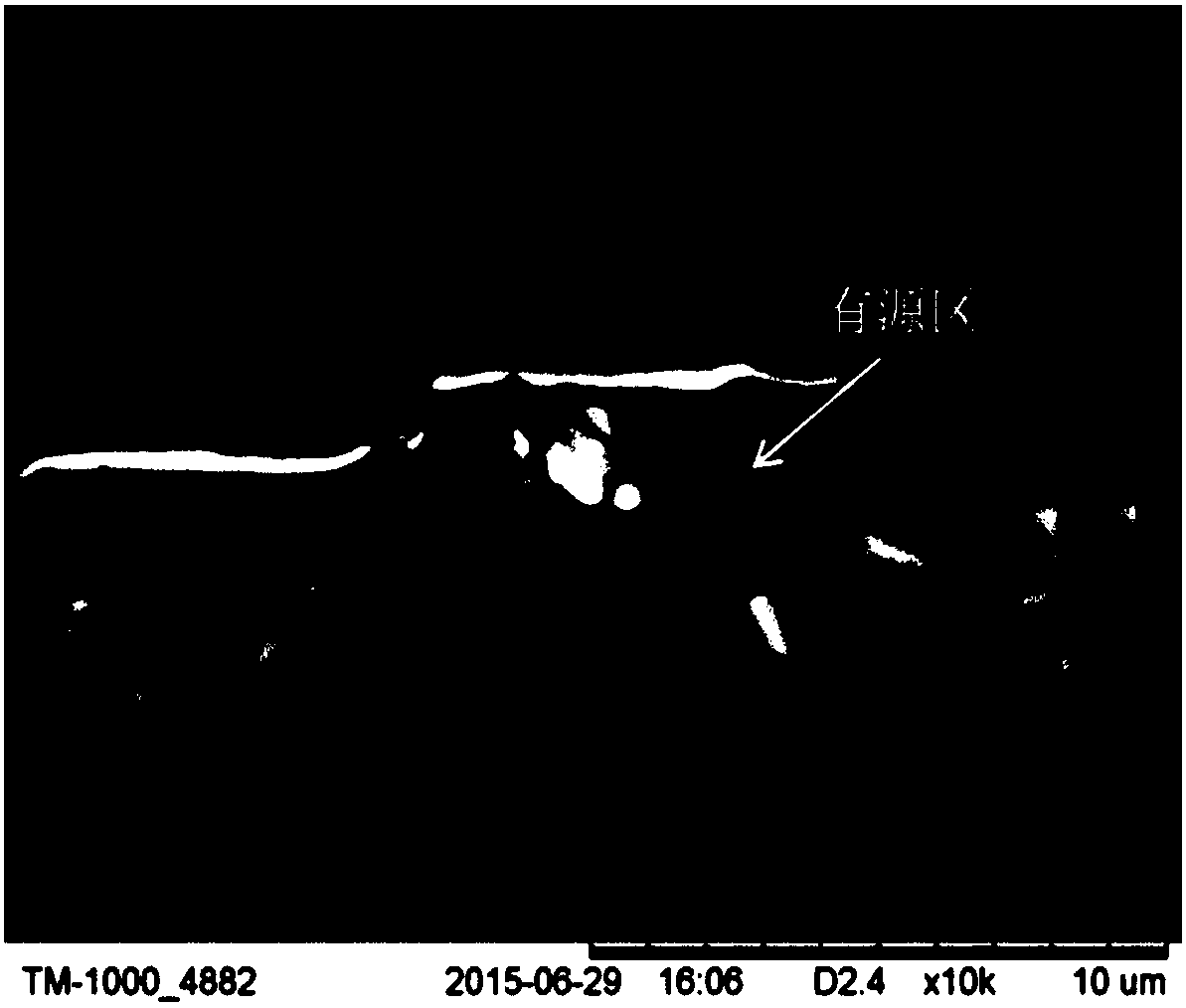

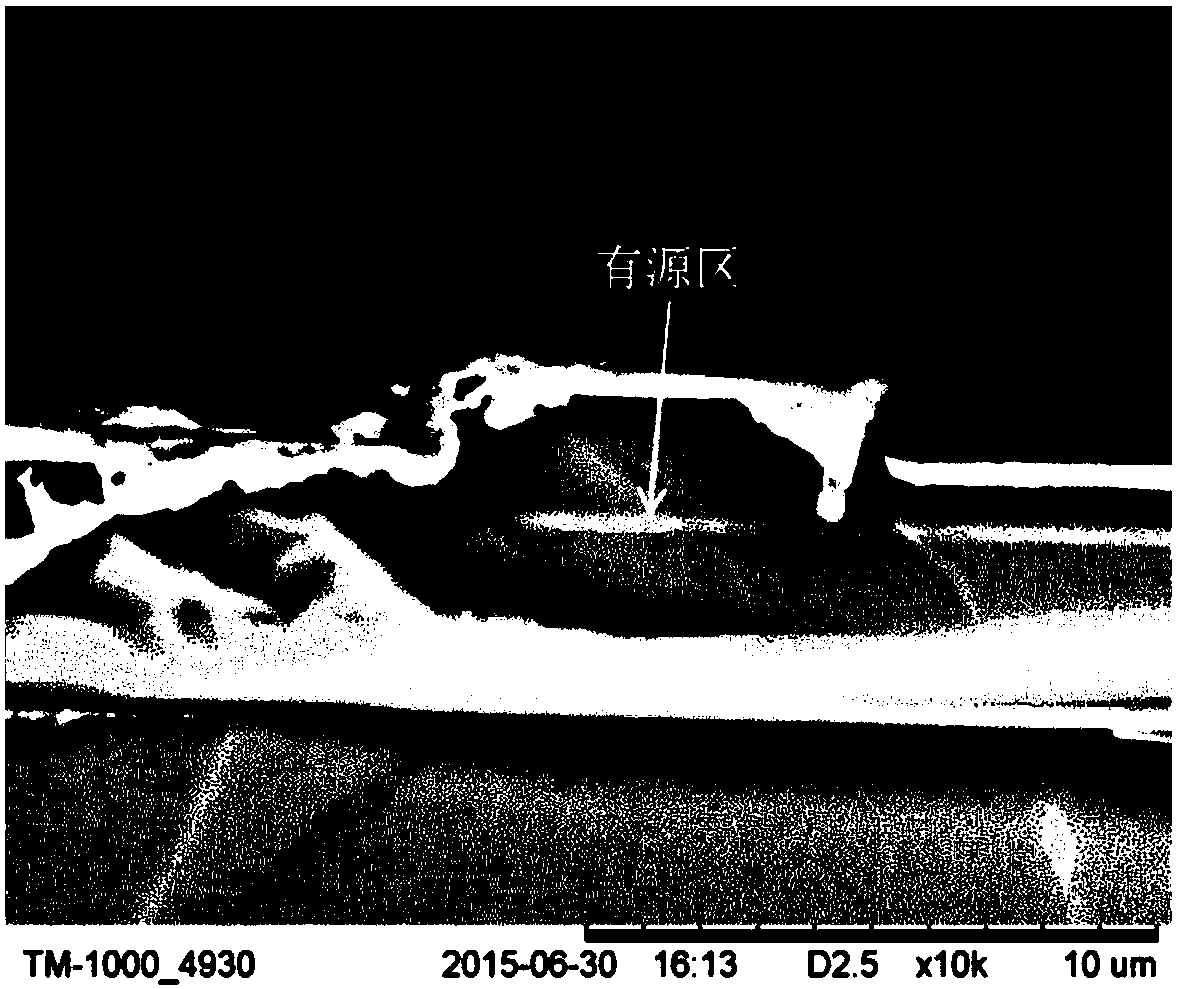

[0025] ②Preparation of cantilever structure on laser cavity surface: using H 2 o 2 Corrosion the failed laser, the corrosion condition is 50 ℃ water bath heating for 8h, under this condition, the corrosion liquid hardly affects the InAs / GaAs laser structure, the selection ratio is about 30:1; that is, the corrosion rate of GaAs is Ge substrate The corrosion rate is less than 1 / 30. Therefore, by choosing a suitable etching time, the Ge substrate can be etched laterally without corroding the epitaxial structure of the laser on the substrate, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com