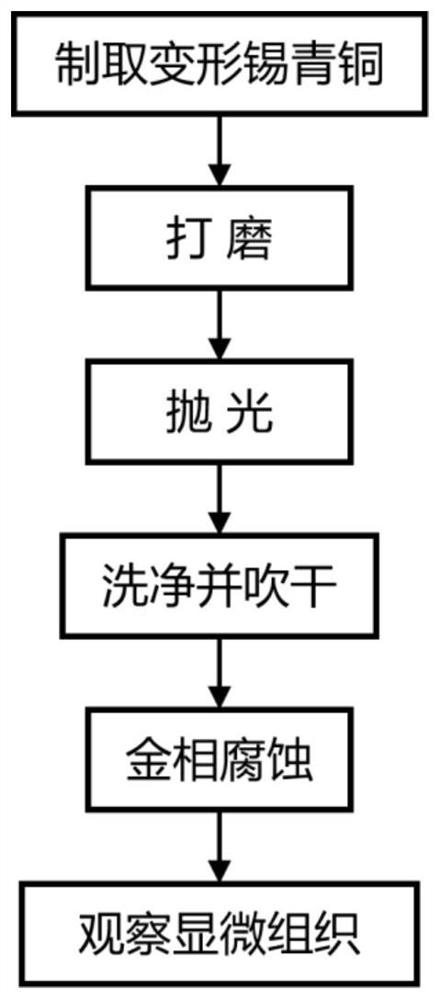

Metallographic corrosive for deformed tin bronze and crystal grain display method thereof

A display method, tin bronze technology, applied in the preparation of test samples, instruments, analysis materials, etc., can solve the problem of inability to clearly distinguish the grain size and shape, excessive corrosion on the surface of the sample, and affect the accuracy of metallographic structure evaluation Sex and other issues to achieve the effect of avoiding drag marks, avoiding excessive corrosion, and controlling corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

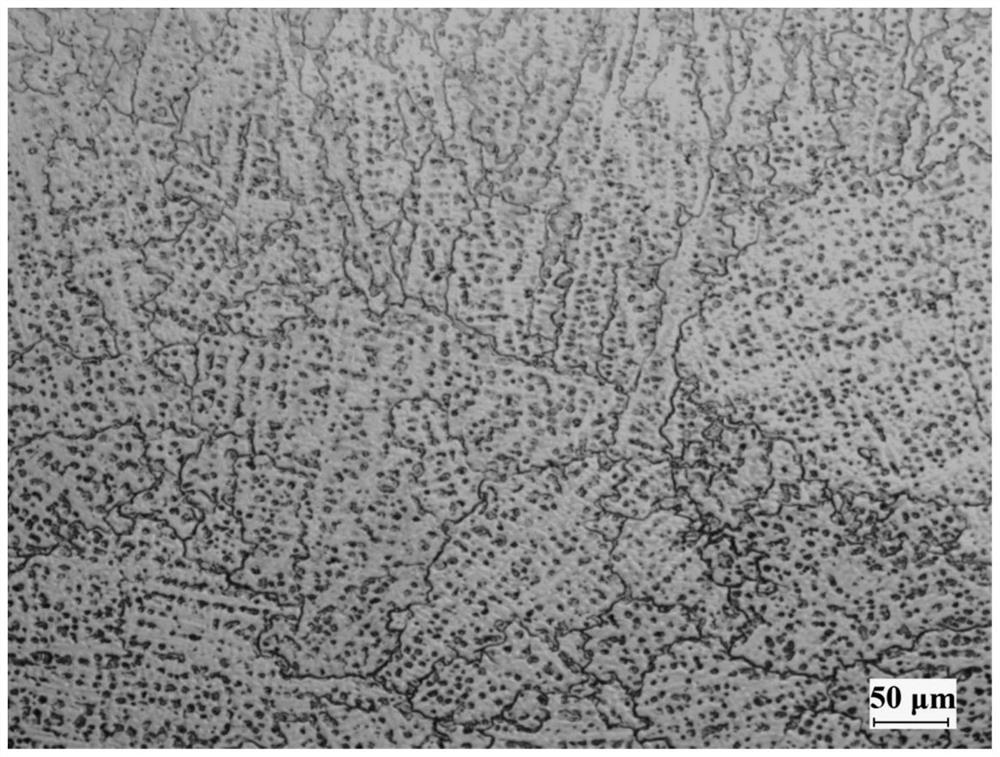

Embodiment 1

[0041] Step (1), by rolling, rolling a tin bronze plate with a grade of SCu5210 and an initial thickness of 1mm into a tin bronze plate with a thickness of 0.8mm, and the rolling deformation is 20%;

[0042] Step (2), cut a sample of 10mm×10mm on the tin bronze plate with the above-mentioned 20% rolling deformation;

[0043] Step (3), using 80 mesh, 400 mesh, 800 mesh, and 1500 mesh sandpaper on the metallographic pre-grinder to polish the above-mentioned sample, until the surface of the sample is smooth and smooth and the scratch direction is consistent;

[0044] Step (4), spray the diamond polishing agent of 1.5 μm on the black velvet cloth, control the rotating speed of the polishing machine to be 500 rpm, and polish the above-mentioned polished sample;

[0045] Step (5), rinse and dry with water and dehydrated alcohol successively after polishing;

[0046] Step (6), take 0.5mL of the metallographic etchant with a plastic tip dropper, drop it on the surface of the sample, ...

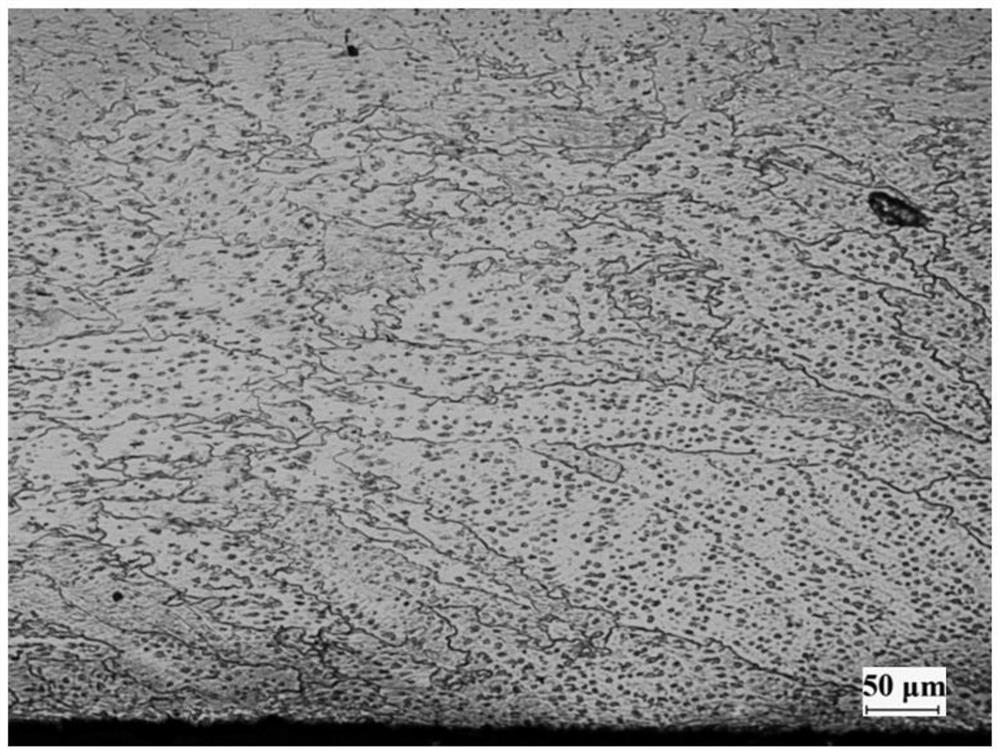

Embodiment 2

[0049] Step (1), by rolling, rolling a tin bronze plate with a grade of SCu5210 and an initial thickness of 1mm into a tin bronze plate with a thickness of 0.6mm, and the rolling deformation is 40%;

[0050] Step (2), cut a sample of 10mm×10mm on the tin bronze plate with the above-mentioned 40% rolling deformation;

[0051] Step (3), using 80 mesh, 400 mesh, 800 mesh, and 1500 mesh sandpaper on the metallographic pre-grinder to polish the above-mentioned sample, until the surface of the sample is smooth and smooth and the scratch direction is consistent;

[0052] Step (4), spray the diamond polishing agent of 1.5 μm on the black velvet cloth, control the rotating speed of the polishing machine to be 500 rpm, and polish the above-mentioned polished sample;

[0053] Step (5), rinse and dry with water and dehydrated alcohol successively after polishing;

[0054] Step (6), take 0.5mL of the metallographic etchant with a plastic tip dropper, drop it on the surface of the sample, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com