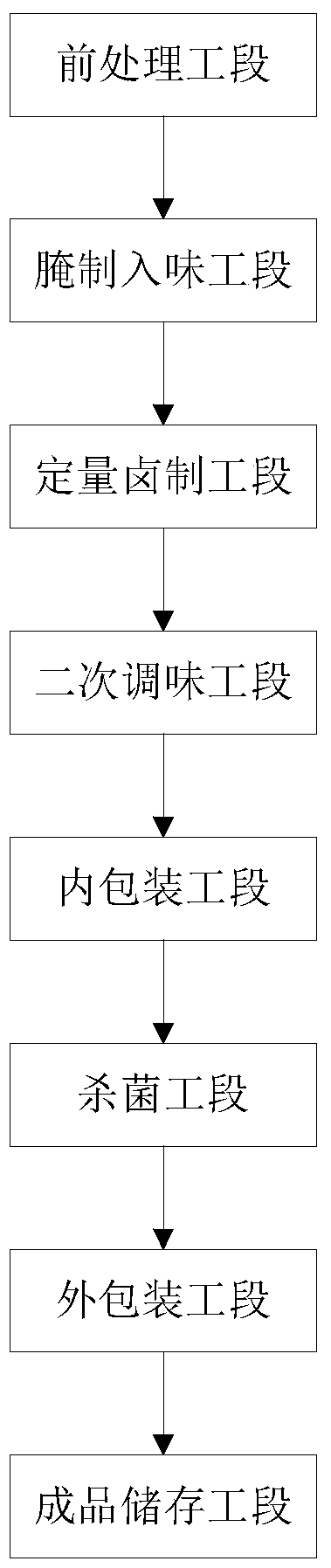

Quantitative marinating production line for meat products

A quantitative technology of marinating and meat products, applied in food heat treatment, food science, etc., can solve the problems of complex operation, harsh production environment, short shelf life, etc., and achieve the effect of uniform taste and flavor, uniform and stable products, and less product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

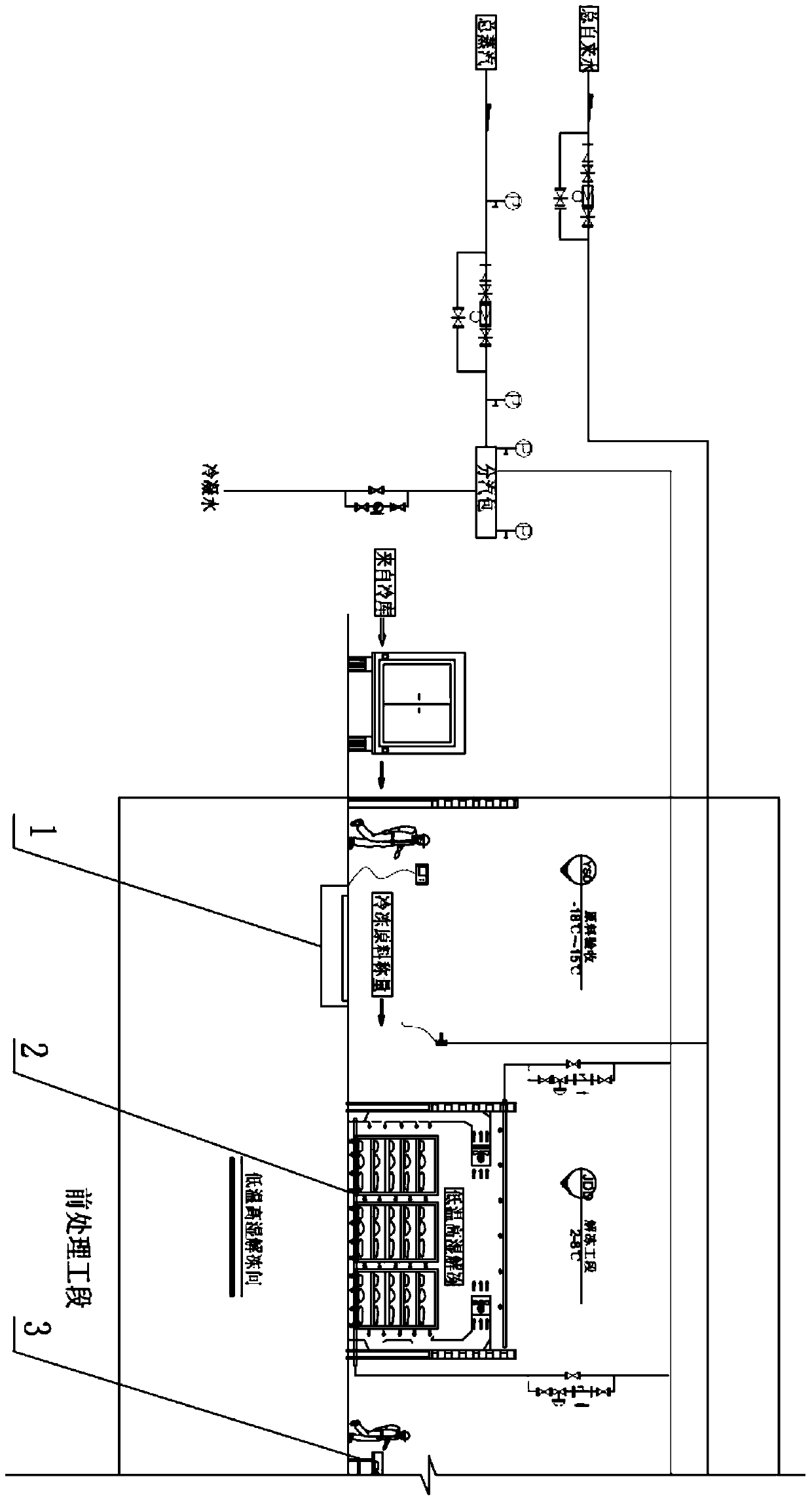

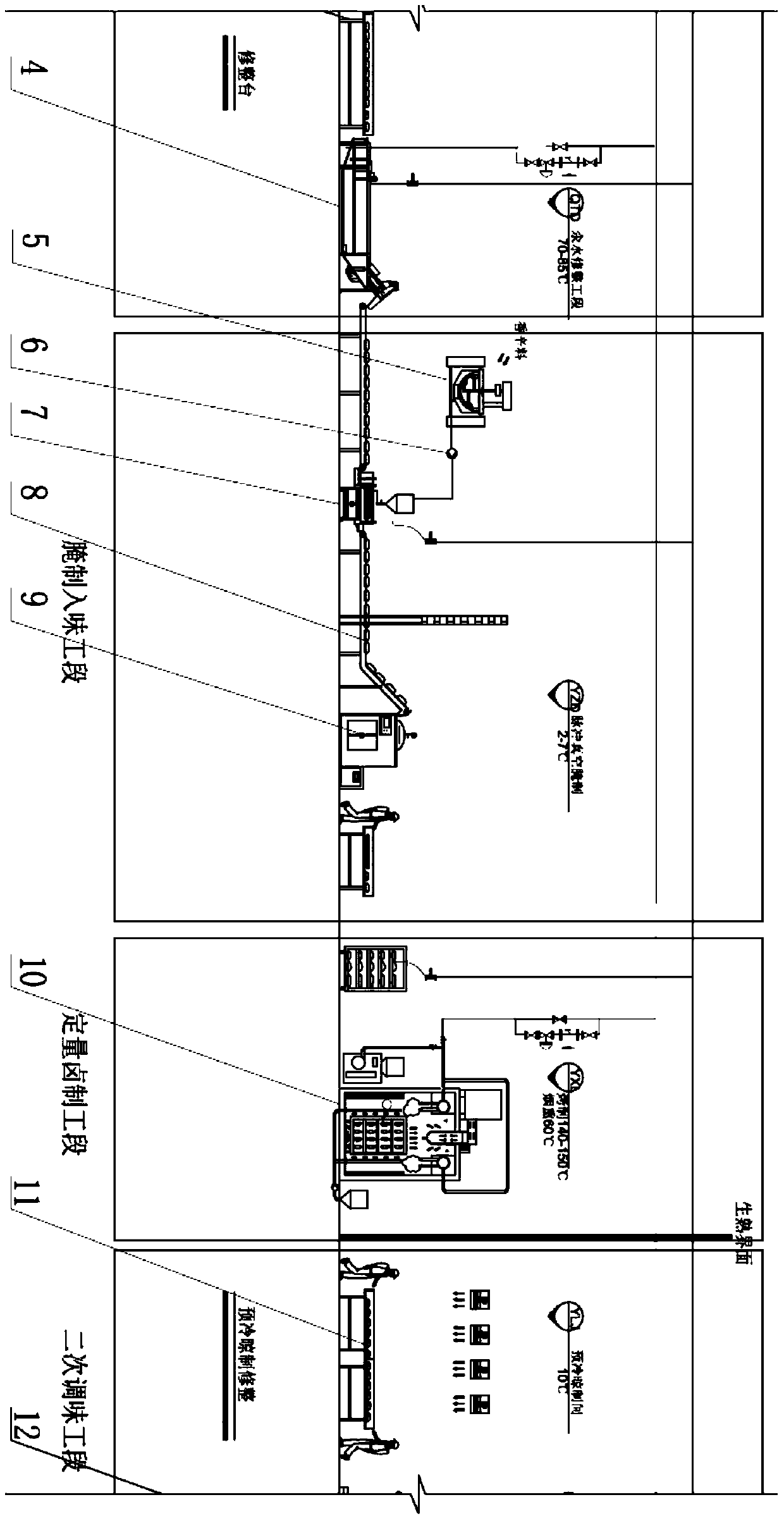

[0029] The invention provides a quantitative marinating production line for meat products, which includes: the raw materials of frozen products that have passed the inspection are transported to the processing workshop by a cold storage or a refrigerated truck, and the raw materials are weighed by a weighbridge 1 to confirm the processed quantity. Before processing, the raw materials enter the high-humidity and low-temperature thawing warehouse 2 for slow thawing. After 12 to 16 hours (the thawing time is different for different raw materials), the central temperature of the raw materials reaches -2°C, which meets the processing needs. Then the raw material is placed on the trimming table 3 for trimming and segmentation to remove the lymph and fascia on the surface of the material. After trimming, it can be placed on the conveyor belt and enter the water scalding machine 4. Adjust the water scalding temperature and conveying speed of the water scalding machine 4 to meet For raw...

Embodiment 2

[0038]The invention provides a quantitative marinating production line for meat products, which includes: the raw materials of frozen products that have passed the inspection are transported to the processing workshop by a cold storage or a refrigerated truck, and the raw materials are weighed by a weighbridge 1 to confirm the processed quantity. Before processing, the raw materials enter the high-humidity and low-temperature thawing warehouse 2 for slow thawing. After 12 to 16 hours (the thawing time is different for different raw materials), the central temperature of the raw materials reaches 0°C, which meets the processing needs. Then the raw material is placed on the trimming table 3 for trimming and segmentation to remove the lymph and fascia on the surface of the material. After trimming, it can be placed on the conveyor belt and enter the water scalding machine 4. Adjust the water scalding temperature and conveying speed of the water scalding machine 4 to meet For raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com