Industrial treatment method of high-valence chromium wastewater

A treatment method, high-valent chromium technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. and other problems, to achieve the effect of improving treatment capacity, reducing the production of high-salt wastewater, and achieving obvious treatment effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for industrialized treatment of high-priced chromium wastewater, comprising the following steps:

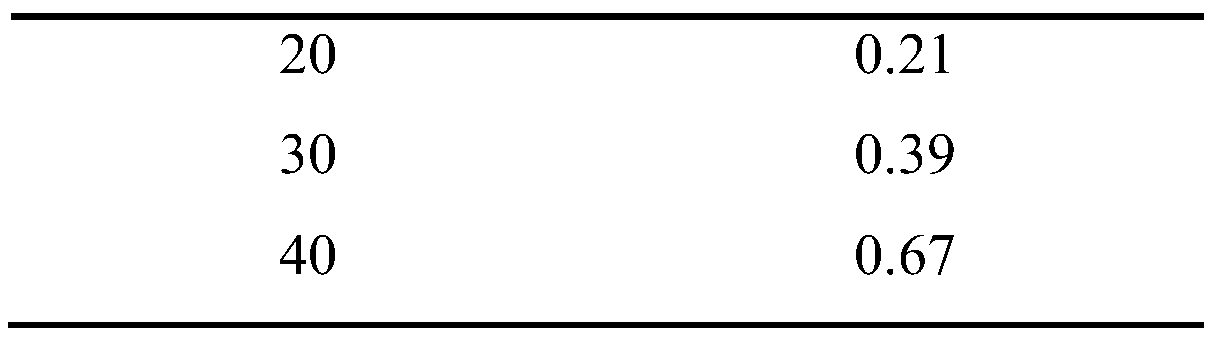

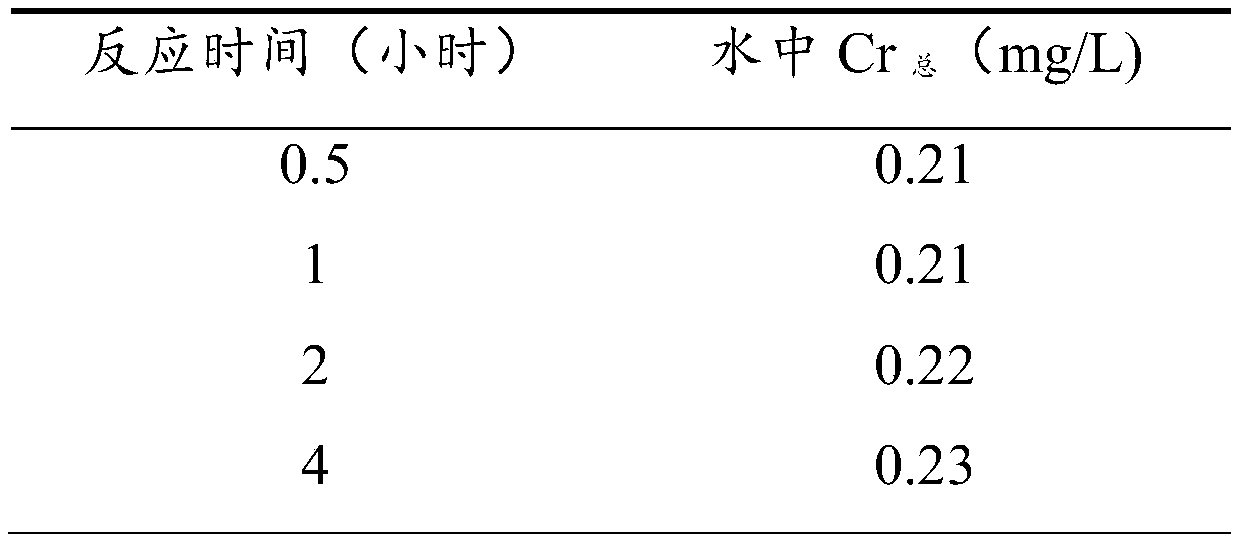

[0018] Under mechanical stirring, add industrial chromium waste water 2000L and water treatment defoamer BYK2kg in the 5000L reactor, (in the industrial chromium waste water, H 2 CrO 4 The concentration is 22690mg / L, H 2 CrO 4 The calculated amount is 45.38kg=2000L*22690mg / L) Stir evenly, add dropwise 57.69kg of 30% hydrazine hydrate (the molar ratio of hexavalent chromium to 30% hydrazine hydrate is 1:0.75), react at 20°C for 0.5h, Add 46.15 kg of sodium hydroxide to precipitate, and filter after the precipitation is complete, separate the precipitate from the supernatant to obtain a clear water phase, and take the supernatant to detect Cr 总 content, C Cr总 = 0.21 mg / L.

Embodiment 2

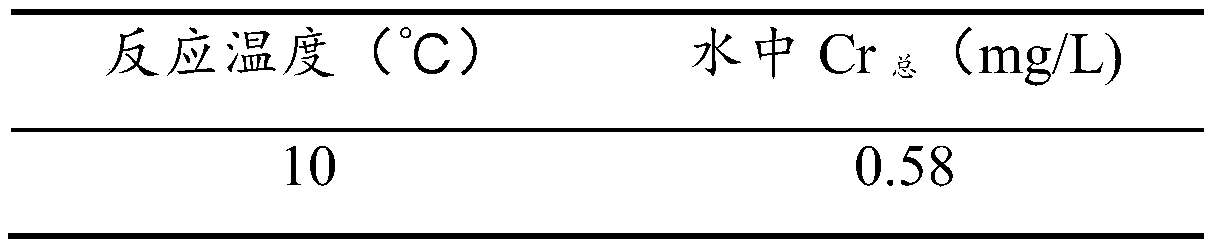

[0020] An industrial treatment method for high-valent chromium wastewater, the steps are the same as in Example 1, except that the reaction is carried out at 10°C for 0.5h.

Embodiment 3

[0022] An industrialized treatment method for high-valent chromium wastewater, the steps are the same as in Example 1, except that the reaction is carried out at 30°C for 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com