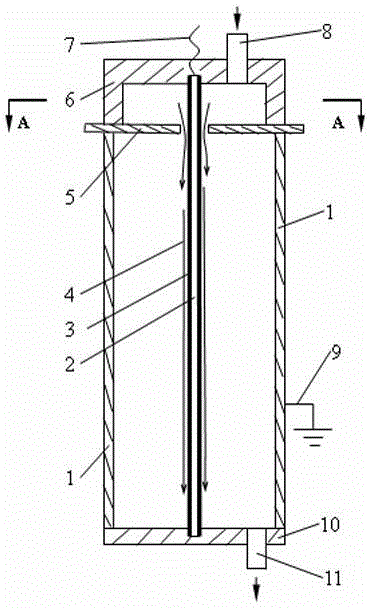

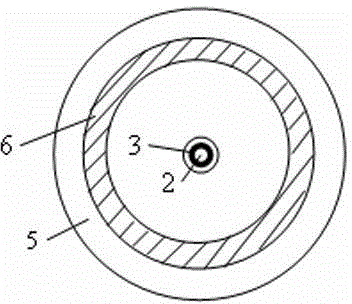

Non-uniform electric field liquid sterilization processing chamber

A non-uniform electric field and sterilization treatment technology, which is applied in the field of sterilization treatment chambers, can solve the problems of low electric field strength, low sterilization rate, and small electrode spacing, etc., and achieve simple structure, improved sterilization effect, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Connect the high-voltage DC power supply to figure 1 The voltage is adjusted to 26kV on the inner electrode, and the outer electrode is grounded. Inoculate beer yeast in sterile water with a bacterial content of 10 6 cfu / ml, after the bacterial liquid flows through the sterilization chamber, the bacterial content is reduced to 100cfu / ml, which meets the sterilization requirements.

Embodiment 2

[0023] Connect the high voltage pulse power supply to figure 1 On the electrode, the voltage is adjusted to 50kV, the pulse width is 10μm, and the pulse repetition frequency is 1Hz. Make the initial bacteria content 6×10 6 After cfu / ml of orange juice flows through the sterilization chamber, the number of viable bacteria in the orange juice is reduced to 2×10 3 cfu / ml, the effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com