Paint mist capturing water cyclone

A water cyclone and paint mist technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve problems affecting the capture effect of paint mist, blockage of high-pressure equipment, accumulation of paint mist, etc., and achieve high water quality Purification performance, increase the total amount, and avoid the effect of paint mist accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

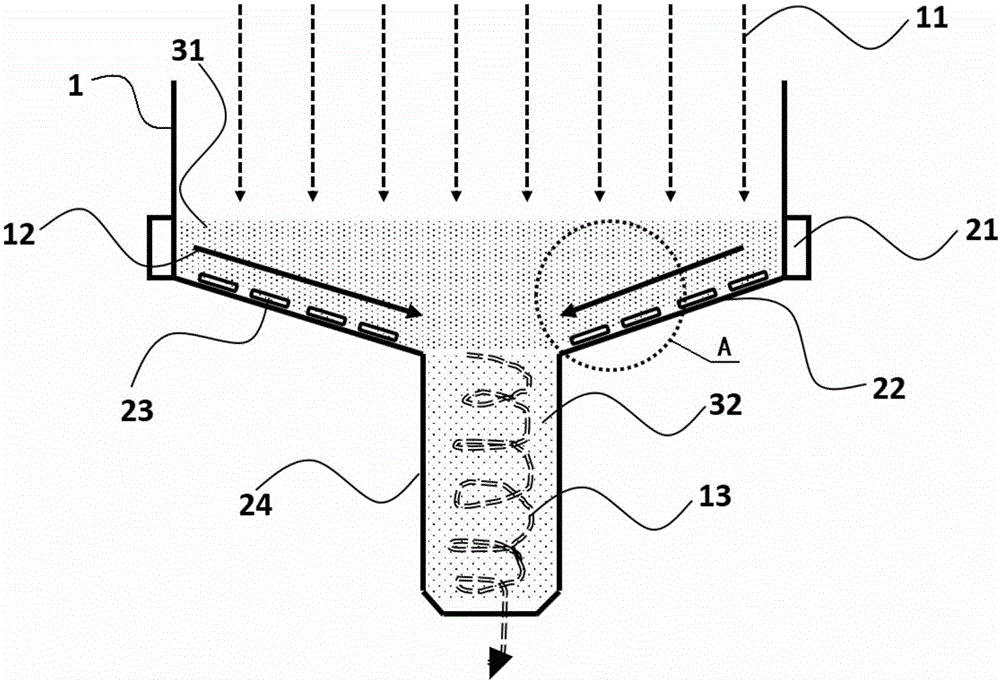

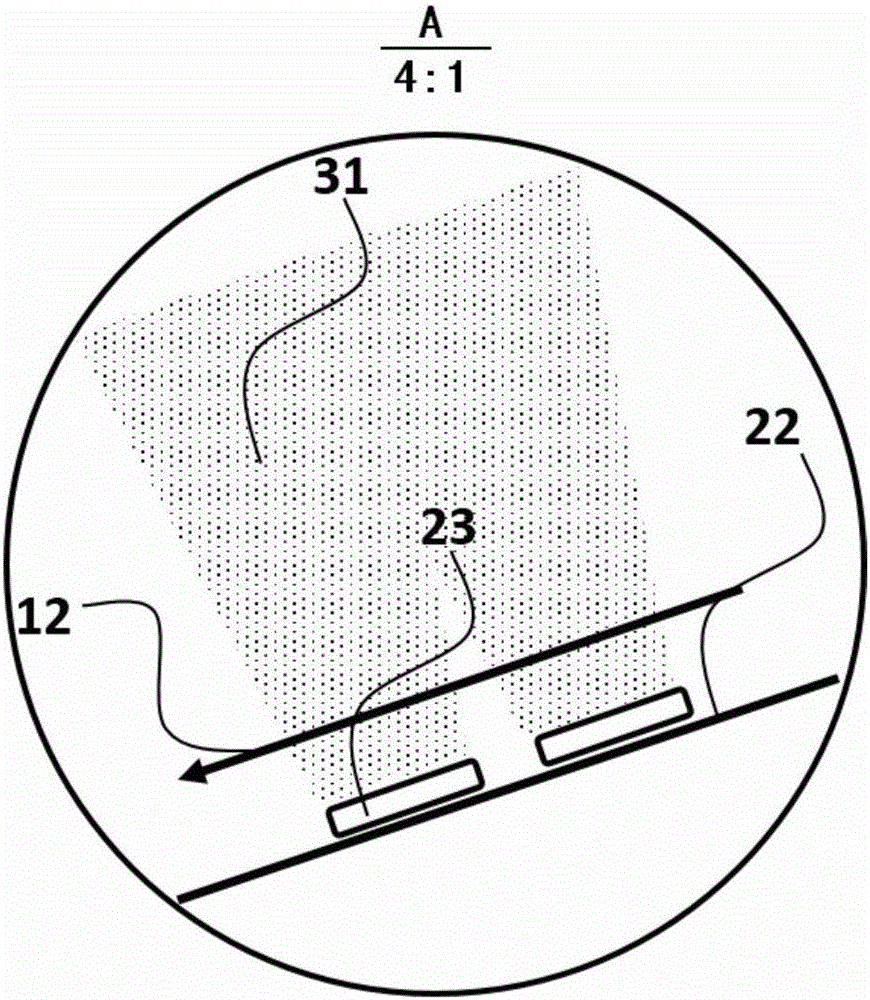

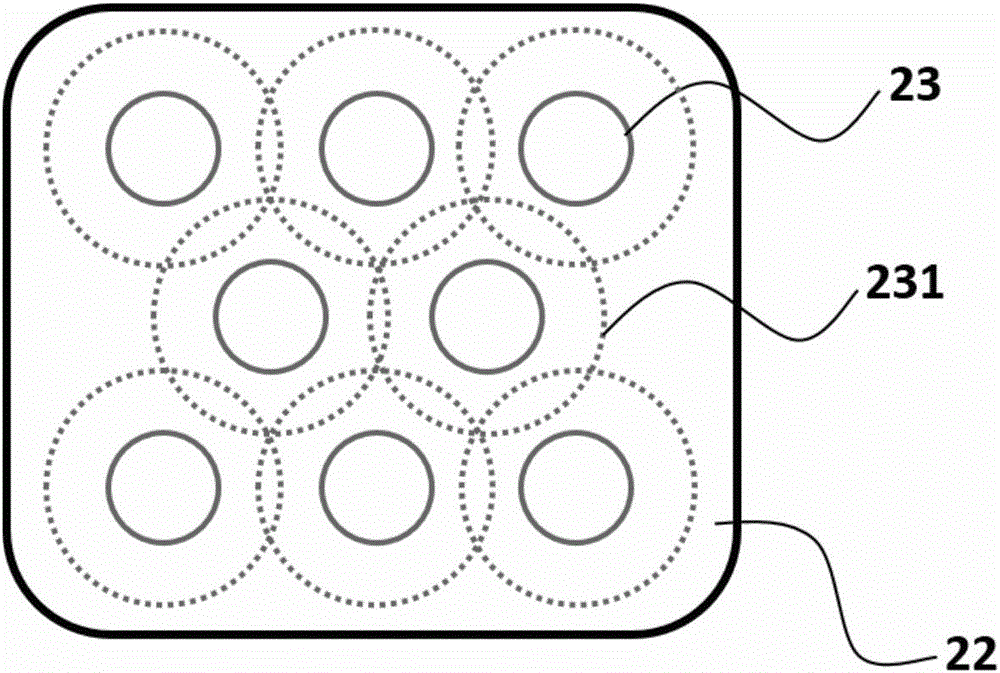

[0032] see figure 1 , the paint mist capture water cyclone in the illustration includes a cylinder 1 and a water cyclone 24. The cylinder 1 in the illustration is a straight cylinder, and the bottom of its inner cavity is an impact plate 22 with an inverted conical bottom. The middle of the impact plate 22 The position is connected to the water cyclone 24, and the inner cavity of the cylinder and the water cyclone are connected to each other; an overflow 21 is set on the outer wall of the cylinder 1, and the overflow flow 12 outside the cylinder flows to the impact plate through the overflow, and the impact plate 22 is laid with an oscillating slice 23, such as figure 2 As shown, part of the overflow water flow 12 forms an oscillating water mist 31 through high-frequency oscillation.

[0033] In this embodiment, the impact plate 22 is an inverted conical structure with high surroundings and low center, wherein the overflow port 21 is arranged around the height of the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com