Combined paint spray booth

A spray booth, combined technology, applied in the field of new combined spray booth, to achieve the effect of convenient construction, environmental protection, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

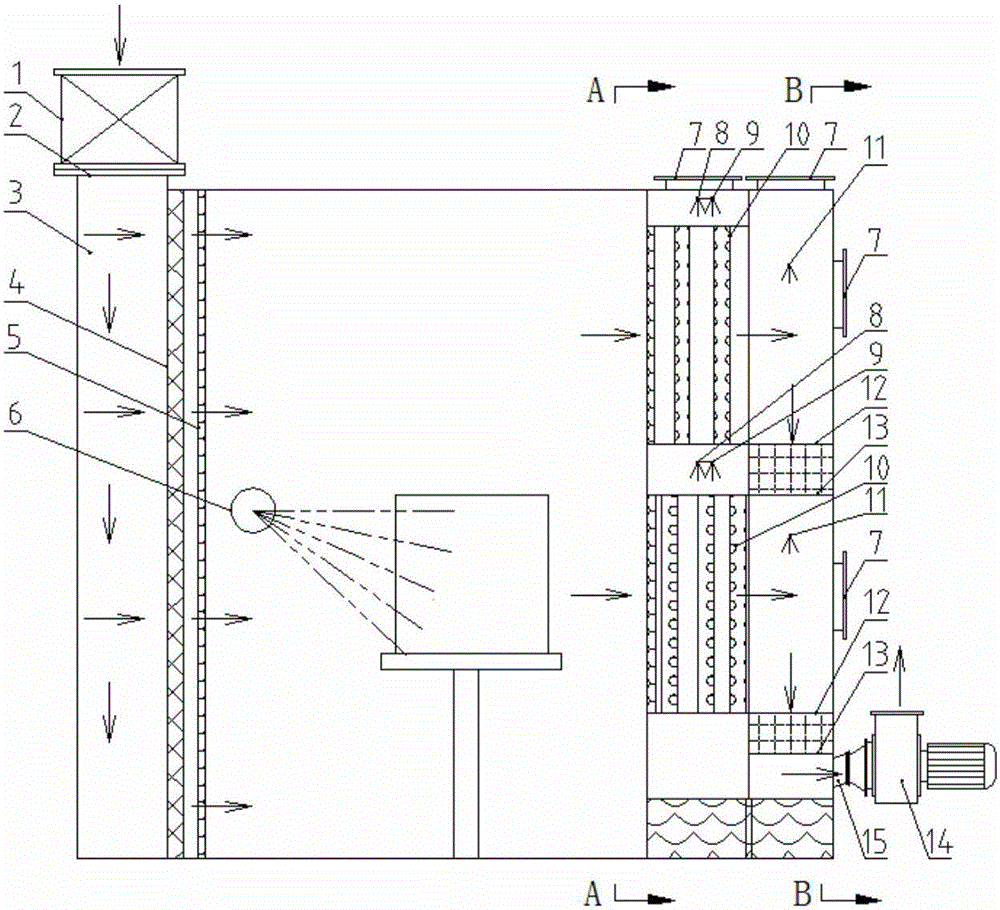

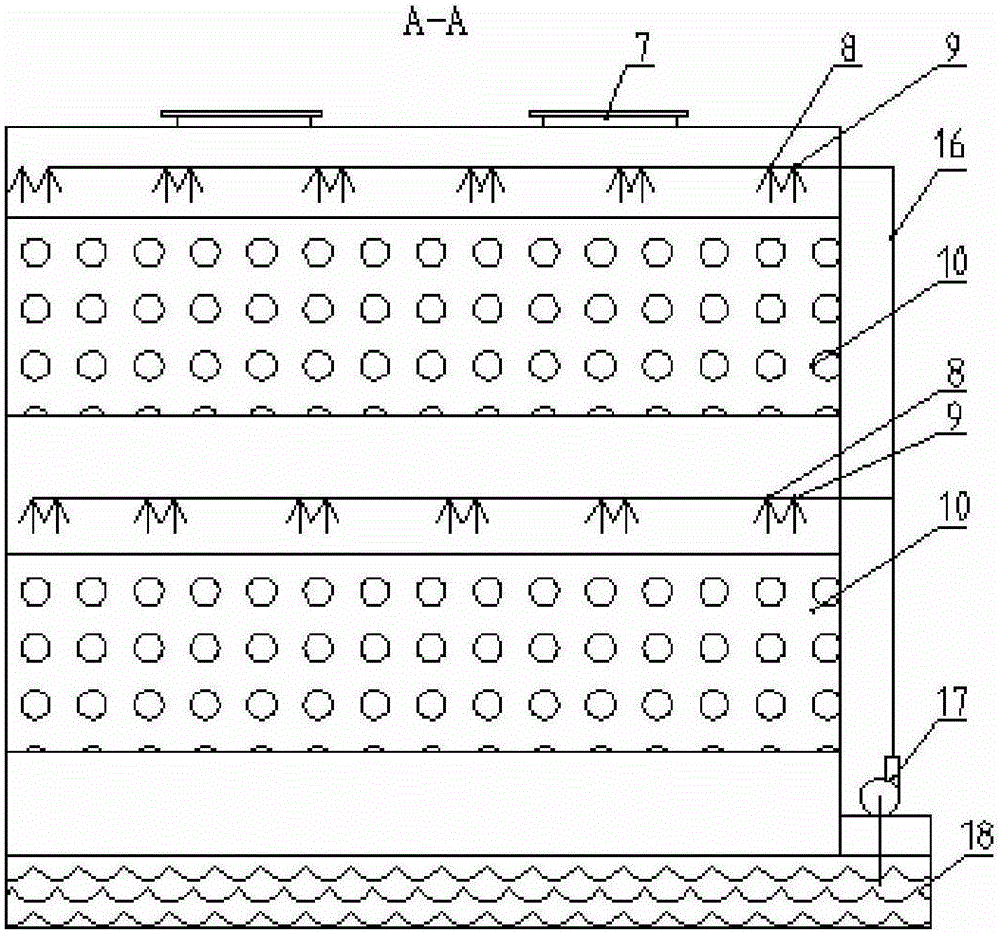

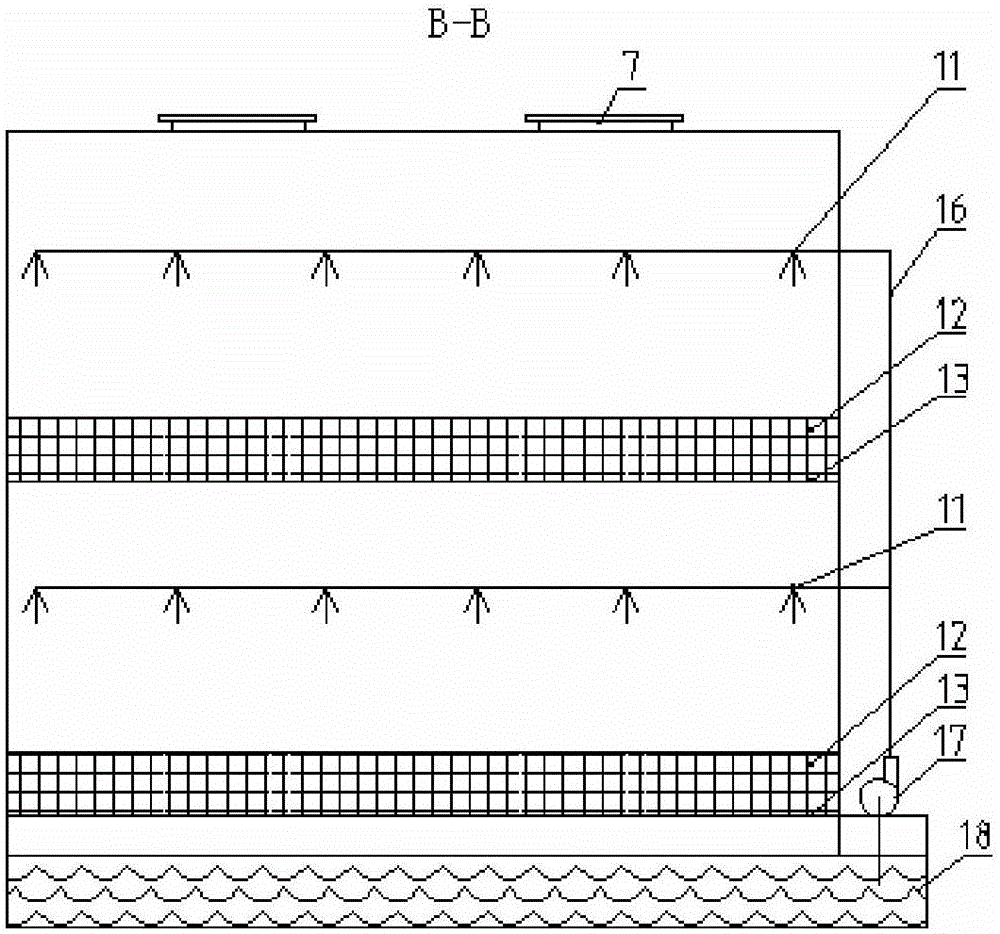

[0033] join figure 1 , the combined spray booth in the illustration is a preferred embodiment of the present invention, specifically including air supply fan 1, air inlet 2, air supply channel 3, filter cotton 4, equalizer plate 5, inspection port 7, flushing nozzle 8, Micro-bubble high-pressure nozzle 9, metal filter plate 10, nozzle 11, biological filler layer 12, grid plate 13, exhaust fan 14, air outlet 15, water pipe 16, water pump 17 and circulating water tank 18.

[0034] Specifically, the spray booth in this embodiment can be divided into an air supply module, a dry-wet combination module, a biological filtration module, and an exhaust module, wherein the air supply module and the exhaust module are respectively arranged on opposite walls of the spray booth. The wet combination module and the biological filtration module are overlapped and arranged in the wall of the spray booth where the exhaust module is located, and are connected in series with the exhaust module. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com