Hardware injection molded switch preparation method

A hardware and switch technology, which is applied in the field of switch preparation, can solve problems such as terminal deformation, quality problems, and time-consuming process of electroplated parts, and achieve the effects of overcoming the influence of switch terminals, saving manpower and cost, and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

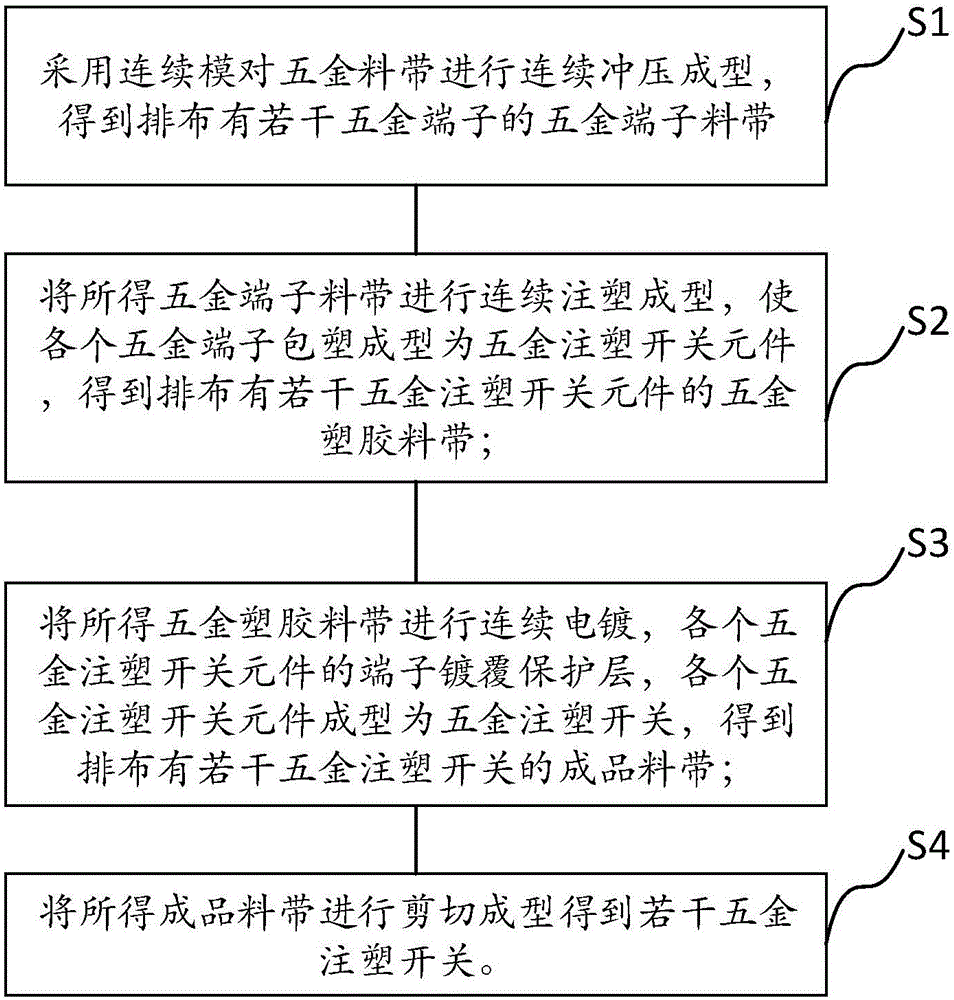

[0034] Such as figure 1 Shown, a kind of preparation method of metal injection switch, comprises the following steps:

[0035] S1. Continuous stamping and forming of the metal strip by using a continuous mold to obtain a metal terminal strip with a plurality of hardware terminals arranged therein;

[0036] S2. Perform continuous injection molding of the obtained metal terminal material strip, so that each metal terminal is molded into a metal injection molded switch element, and a metal plastic plastic strip with a plurality of metal injection molded switch elements arranged therein is obtained;

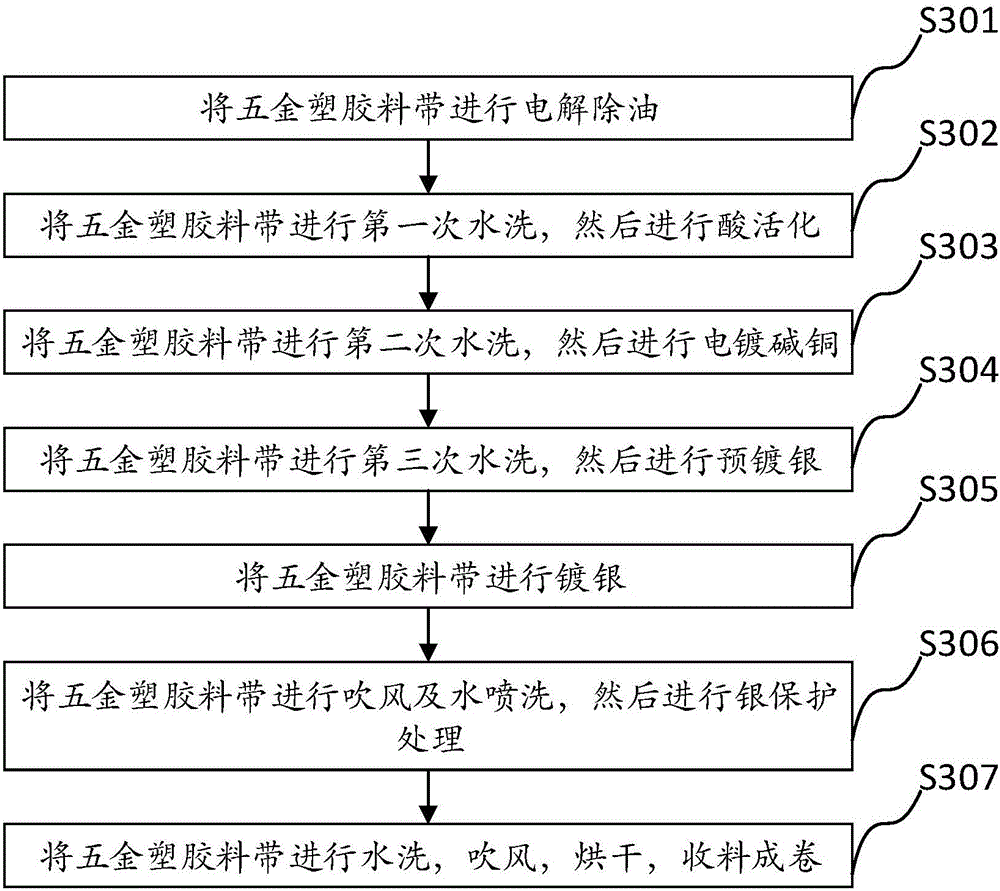

[0037] S3, performing continuous electroplating on the obtained hardware and plastic strips, coating the terminals of each metal injection molded switch element with a protective layer, forming each metal injection molded switch element into a metal injection molded switch, and obtaining a finished strip with a number of metal injection molded switches;

[0038] S4. Cutting and mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com