Flying ash desalination and water washing device

A technology for desalinated water and fly ash, applied in cement production, etc., can solve problems such as inadequate supervision, high cost of fly ash treatment, and inability to safely dispose of fly ash, and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

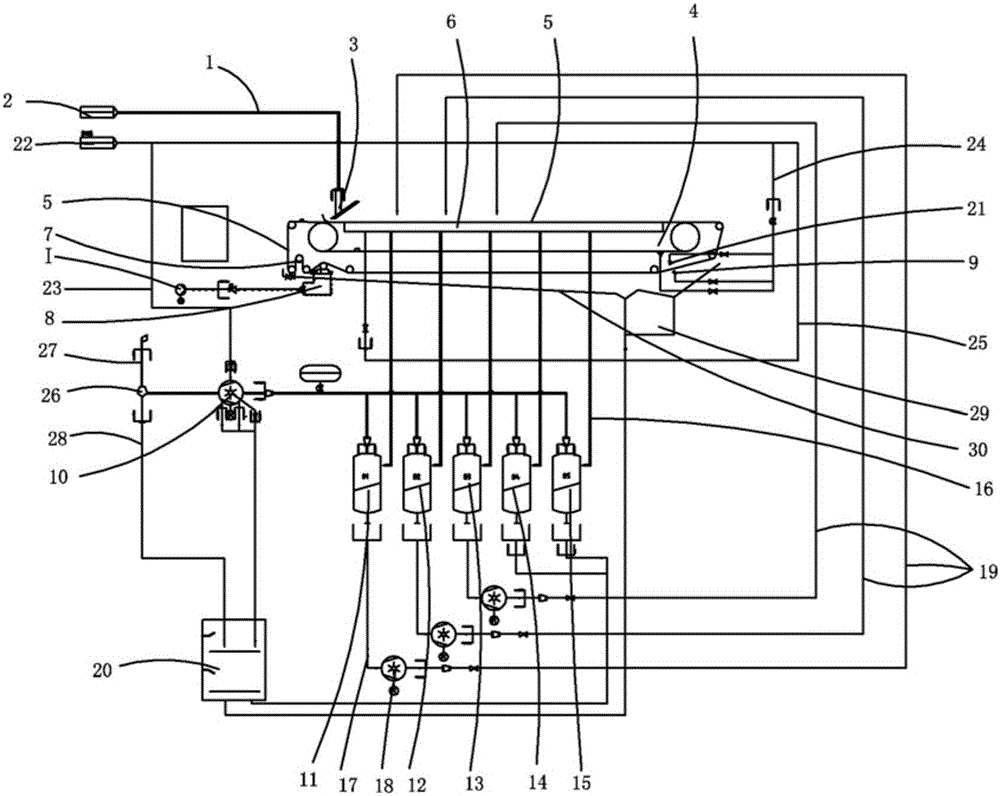

[0016] Examples, see attached figure 1 , a fly ash desalination washing device, comprising a feed pipeline 1, one end of the feed pipeline is connected to a storage 2, and the other end of the feed pipeline is connected to a feeding device 3, and the feeding device mixes a mixture of fly ash and water (and The solid-to-liquid ratio of fly ash and water is 1:4) into the filter cloth 5 of the vacuum belt conveyor 4; the vacuum belt conveyor is provided with a vacuum box 6, and the conveyor belt of the vacuum belt conveyor is a filter cloth, and the filter cloth covers On the vacuum box, the filter cloth is attached with a microporous membrane, the fly ash on the filter cloth is mixed with water, and the filter cloth is continuously running, and the washed fly ash solution is sucked by the vacuum pump of the vacuum suction device. The aqueous solution in the vacuum suction device is pumped out and sent to the drain tank to achieve the effect of solid-liquid separation. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com