Asphalt regenerant as well as preparation method and application thereof

An asphalt regenerating agent and asphalt technology, which is applied in recycling technology, building components, building insulation materials, etc., can solve the problems of poor regeneration effect, low cost performance, poor effect, etc., and achieves a simple and controllable preparation method. Environmentally friendly, effect of improving anti-rutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

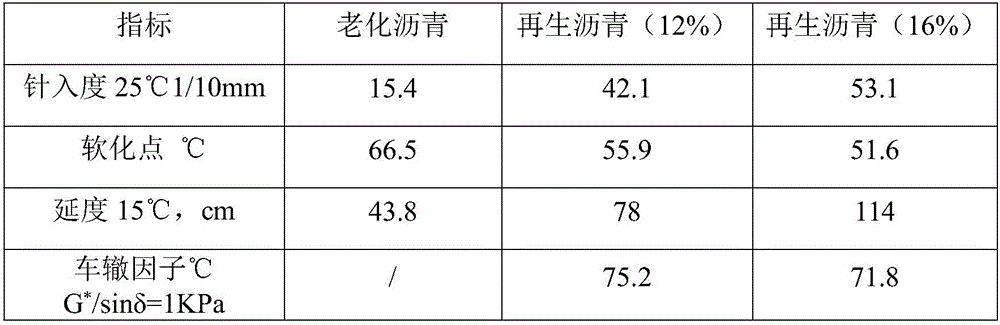

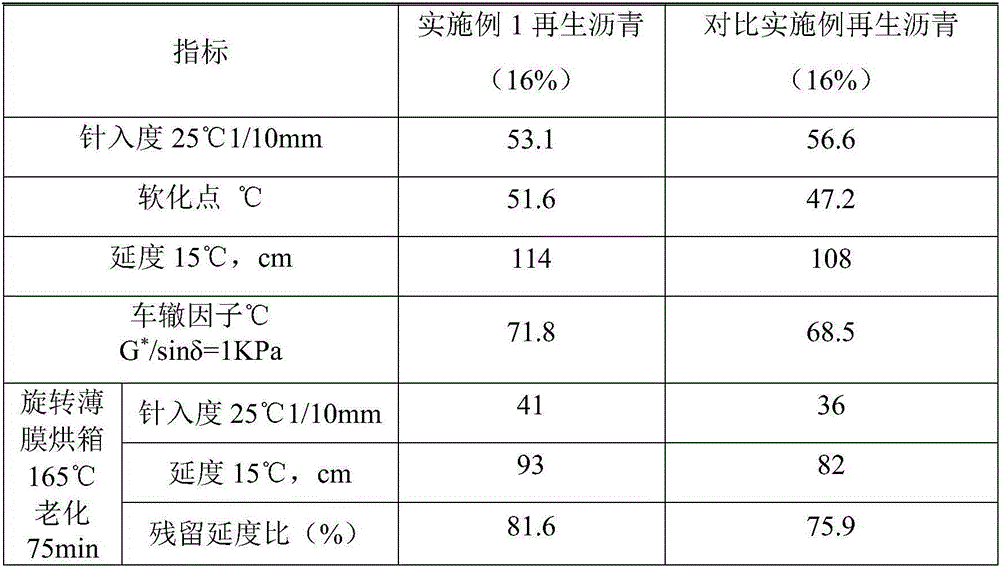

Embodiment 1

[0033] A kind of asphalt regenerant of the present invention is mainly formulated by the following components in parts by mass:

[0034]50 parts of mixed oil; the mixed oil is mainly prepared by mixing rapeseed oil (its aromatic content is greater than 70%, the same below) and waste lubricating oil (its aromatic content is greater than 75%, the same below) in a mass ratio of 1:2. become;

[0035] 25 parts of nano-organic montmorillonite modified asphalt; the penetration of matrix asphalt used in nano-organic montmorillonite-modified asphalt is 75dmm, and the dosage of nano-organic montmorillonite in the nano-organic montmorillonite-modified asphalt is 13%;

[0036] 25 parts of plasticizer dioctyl phthalate;

[0037] Penetrant fatty alcohol polyoxyethylene ether 3 parts.

[0038] The preparation method of the above-mentioned asphalt rejuvenator in this embodiment specifically includes the following steps: preheat the reactor to 130°C, weigh 50 parts of mixed oil into the reac...

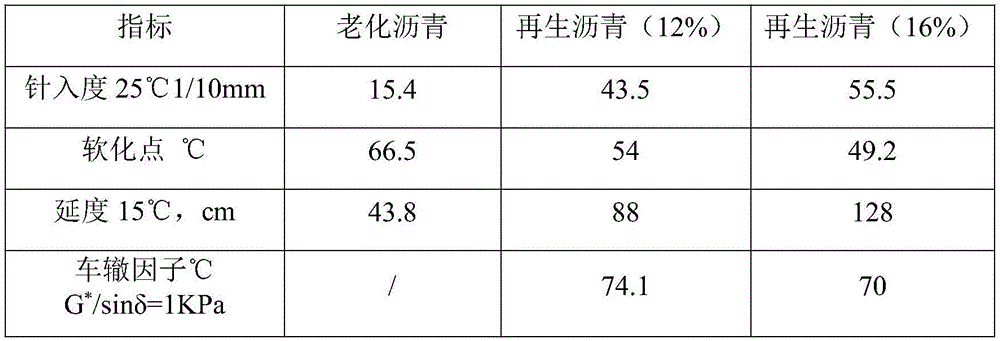

Embodiment 2

[0046] A kind of asphalt regenerant of the present invention is mainly formulated by the following components in parts by mass:

[0047] 45 parts of mixed oil; the mixed oil is mainly formed by mixing rapeseed oil and furfural extracted oil (its aromatic content is greater than 75%, the same below) in a mass ratio of 1:2.5;

[0048] 30 parts of nano-organic montmorillonite modified asphalt; the penetration of matrix asphalt used in nano-organic montmorillonite-modified asphalt is 75dmm, and the dosage of nano-organic montmorillonite in the nano-organic montmorillonite-modified asphalt is 8%;

[0049] 30 parts of plasticizer dioctyl phthalate;

[0050] 2 parts of penetrant dodecyltrimethylammonium bromide.

[0051] The preparation method of the above-mentioned bitumen regenerant in this embodiment specifically includes the following steps: preheating the reactor to 120°C, weighing 45 parts of mixed oil into the reactor according to the ratio of rapeseed oil and furfural extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com