High-entropy alloy with high strength and toughness and preparation method thereof

A high-entropy alloy and toughness technology, applied in the field of high-entropy alloys and their preparation, can solve the problems of poor matching of strength and toughness of high-entropy alloys, and achieve the effects of good safety, simple and reliable preparation methods, and convenient acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

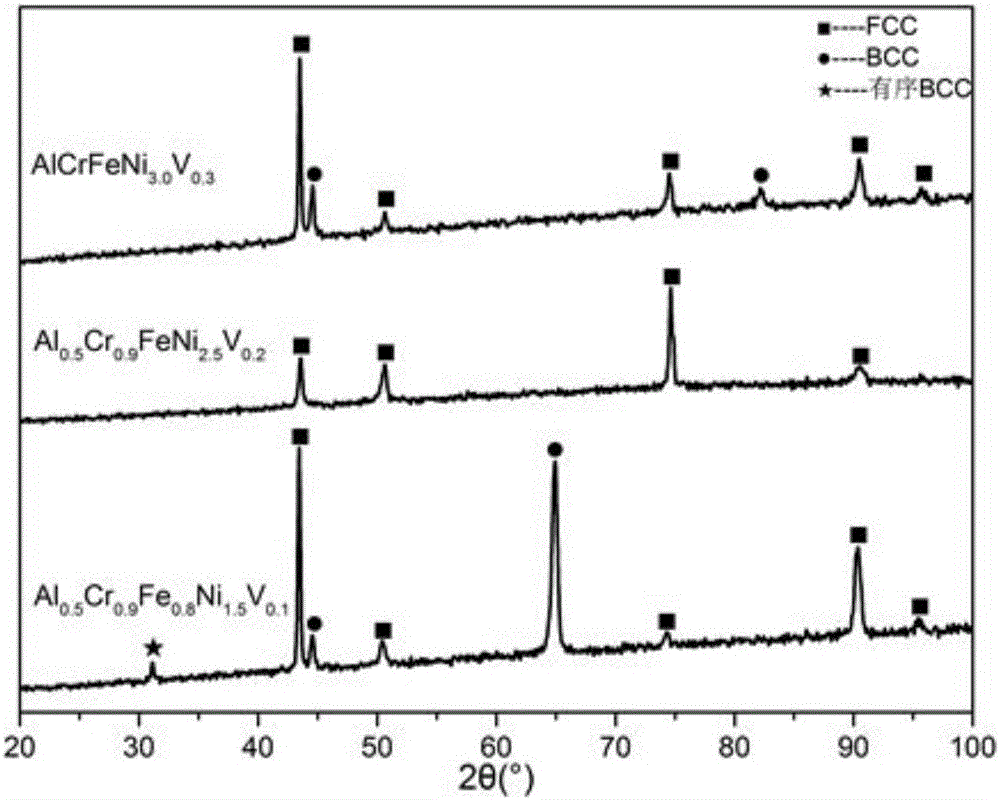

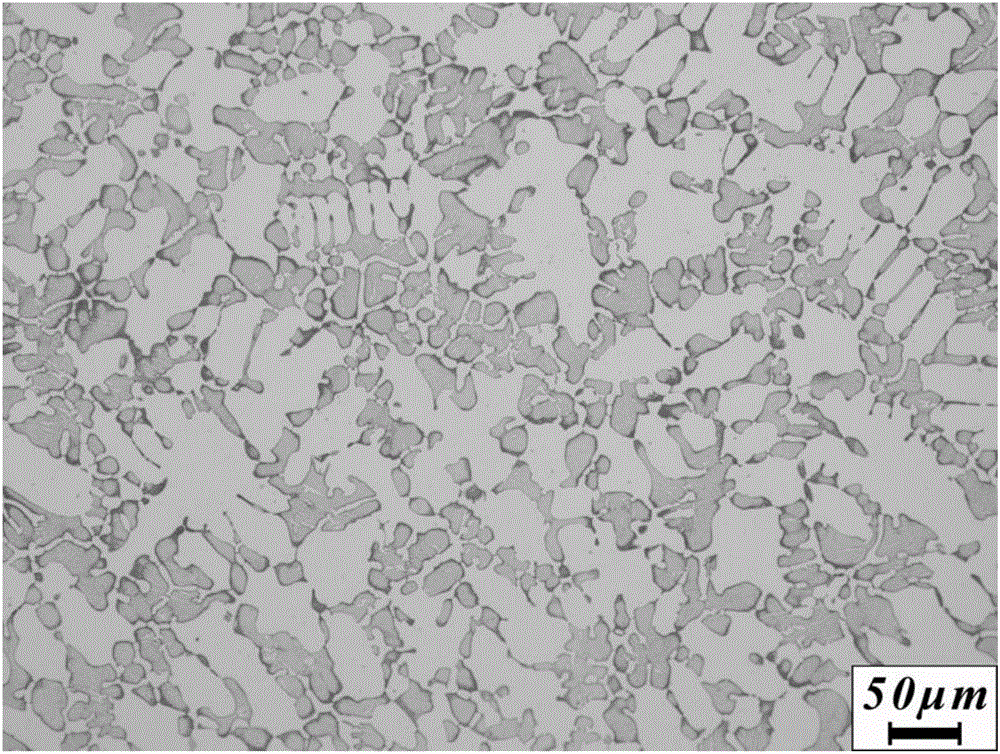

[0035] A method for preparing a high-entropy alloy having both strength and toughness, the high-entropy alloy being Al in molar ratio 0.5 Cr 0.9 Fe 0.8 Ni 1.5 V 0.1 ; The specific steps of the method are as follows:

[0036] (1) Utilize No. 60 SiC sandpaper and grinder to remove surface impurities and oxides of elemental Al, Cr, Fe, Ni and V, then use acetone to clean, and weigh Al, Cr, Fe, Ni and V with a total mass of 80g, And ultrasonic cleaning twice;

[0037] (2) Put Al, Cr, Fe, Ni and V after ultrasonic cleaning in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of less than or equal to 1.0×10 ﹣3 Carry out arc melting under MPa to obtain alloy liquid, stir and cool to obtain alloy ingot;

[0038] (3) Repeat the arc melting, stirring and cooling process in the step (1) after the alloy ingot is turned over;

[0039] (4) repeat step (3) 2 times, obtain the Al described in the present embodiment 0.5 Cr 0.9 Fe 0.8 ...

Embodiment 2

[0046] A method for preparing a high-entropy alloy having both strength and toughness, the high-entropy alloy being Al in molar ratio 0.5 Cr 0.9 FeNi 2.5 V 0.2 ; The specific steps of the method are as follows:

[0047] (1) Utilize No. 60 SiC sandpaper and grinder to remove surface impurities and oxides of elemental Al, Cr, Fe, Ni and V, then use acetone to clean, and weigh Al, Cr, Fe, Ni and V with a total mass of 80g, And ultrasonic cleaning twice;

[0048] (2) Put Al, Cr, Fe, Ni and V after ultrasonic cleaning in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of less than or equal to 1.0×10 ﹣3 Carry out arc melting under MPa to obtain alloy liquid, stir and cool to obtain alloy ingot;

[0049] (3) Repeat the arc melting, stirring and cooling process in the step (1) after the alloy ingot is turned over;

[0050] (4) repeat step (3) 2 times, obtain the Al described in the present embodiment 0.5 Cr 0.9 FeNi 2.5 V 0...

Embodiment 3

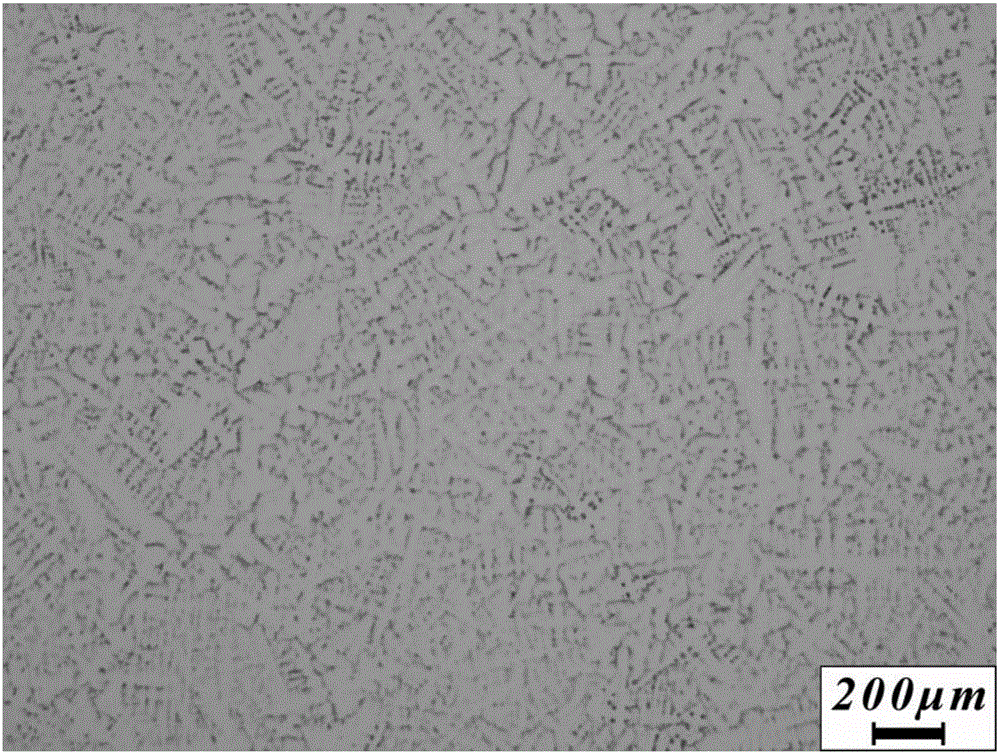

[0057] A method for preparing a high-entropy alloy having both strength and toughness, the high-entropy alloy being AlCrFeNi in molar ratio 3.0 V 0.3 ; The specific steps of the method are as follows:

[0058] (1) Utilize No. 60 SiC sandpaper and grinder to remove surface impurities and oxides of elemental Al, Cr, Fe, Ni and V, then use acetone to clean, and weigh Al, Cr, Fe, Ni and V with a total mass of 80g, Ultrasonic cleaning twice;

[0059] (2) Put Al, Cr, Fe, Ni and V after ultrasonic cleaning in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of less than or equal to 1.0×10 ﹣3 Carry out arc melting under MPa to obtain alloy liquid, stir and cool to obtain alloy ingot;

[0060] (3) Repeat the arc melting, stirring and cooling process in the step (1) after the alloy ingot is turned over;

[0061] (4) repeat step (3) 3 times, obtain AlCrFeNi described in the present embodiment 3.0 V 0.3 High entropy alloys.

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com