Fabric and making method thereof

A technology of fabric and hydrothermal method, which is applied in the direction of plant fiber, textile, papermaking, fiber treatment, etc. It can solve the problems of single function and inability to adapt to changes, etc., and achieve the effect of simple process, multiple functions and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

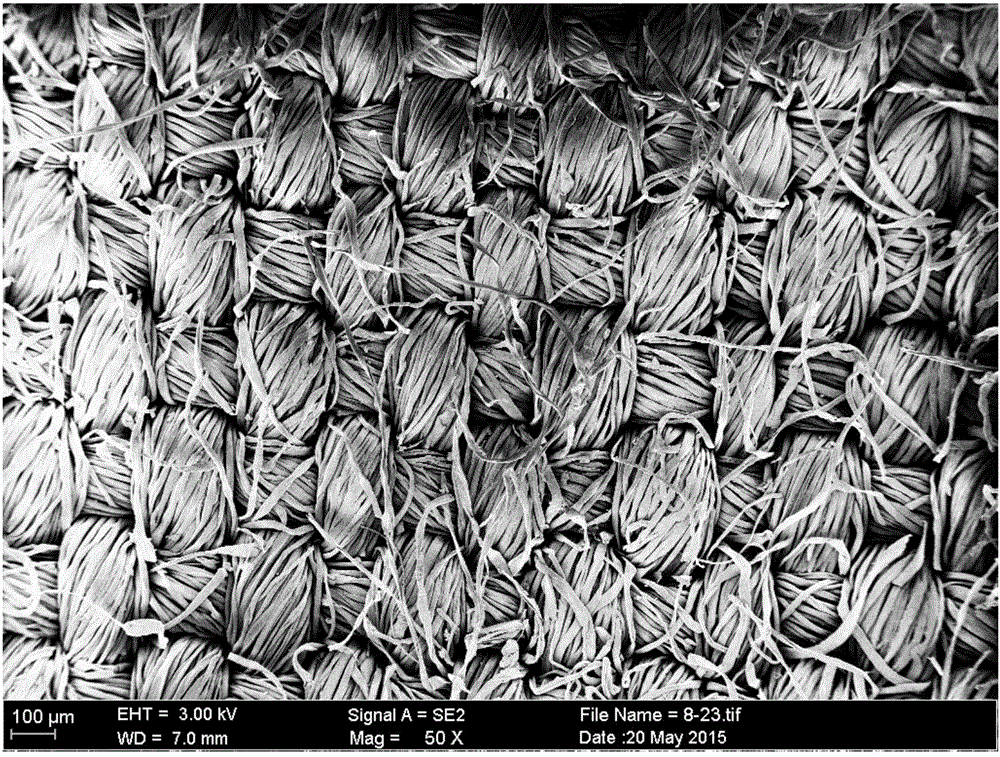

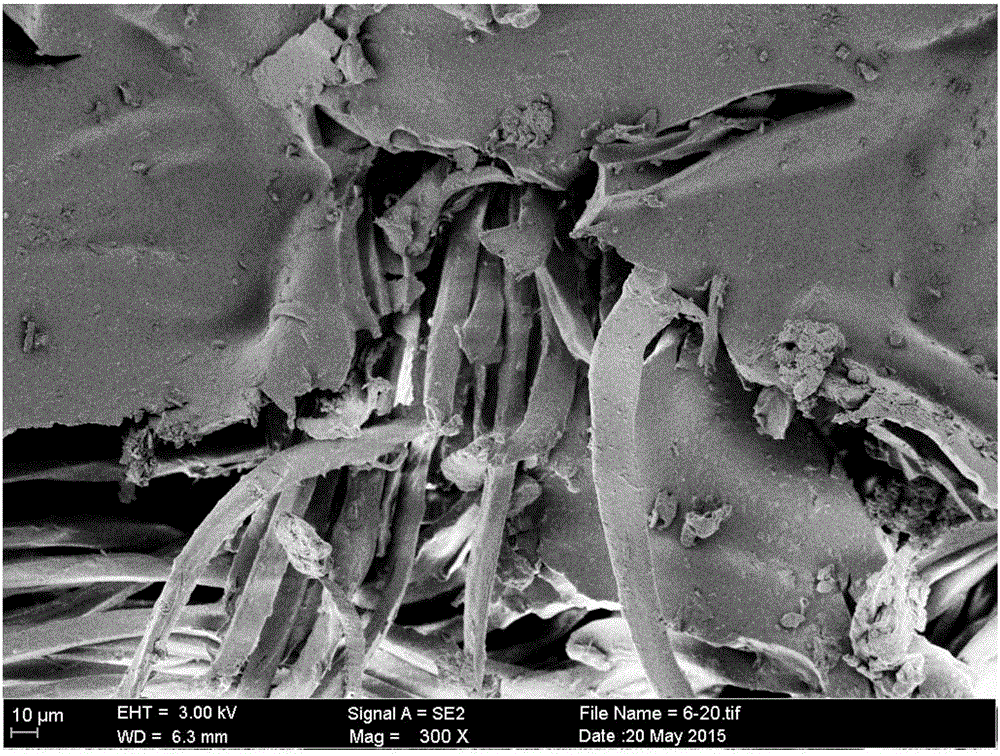

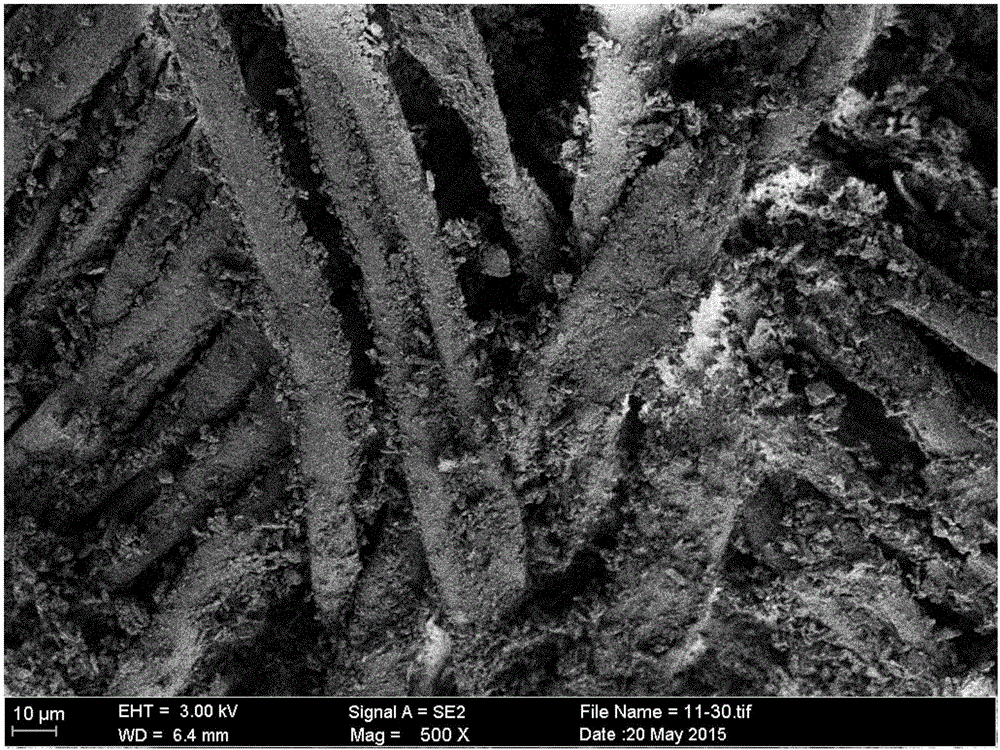

[0032] A kind of preparation method of multifunctional cotton fabric, described preparation method comprises the steps:

[0033] ① Clean the cotton fabric with deionized water and 95% ethanol by ultrasonic oscillation at 80°C to remove particles, dust impurities and residual liquid left after incomplete desizing on the surface of the cotton fabric, and then dry it; Citric acid and catalyst sodium hypophosphite are dissolved in water, and the weight ratio of the citric acid, sodium hypophosphite and water is 3:2:100; the cotton fabric after pretreatment is mixed with citric acid and sodium hypophosphite Two soaking treatments were carried out in the middle, each soaking time was 20min, after soaking, it was taken out, dried at 100°C for 30min, washed with deionized water until neutral, and the modified cotton fabric was obtained.

[0034] ② Use 4mol / L mineralizer sodium hydroxide solution to adjust the filling degree of magnesium hydroxide to 70%, ultrasonically disperse for 10...

Embodiment 2

[0038] The multifunctional cotton fabric (group A) obtained by the unwashed embodiment 1, the multifunctional cotton fabric (group B) obtained by the embodiment 1 of washing 15 times and the multifunctional cotton fabric obtained by the embodiment 1 of washing 30 times (Group C) According to GB / T17591-2006, GB / T5455-2014, FZ / T01004-2008, GB / T20944.3-2008, GB / T17596-1998, GB / T19981.2-2005, GB / T25471, SJ20524 The performance test was carried out, and the results are shown in Table 1.

[0039] Table 1 Performance test results of multifunctional cotton fabric

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com