System for rapidly dispersing and diluting powder polymer in offshore or alpine or fault-block oil field

A technology of polymers and fault blocks, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of feeding influence, polymer moisture absorption and solidification, target fluid affecting oil recovery, etc., and achieve mobile Convenience, simple operation, avoid the effect of damp and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

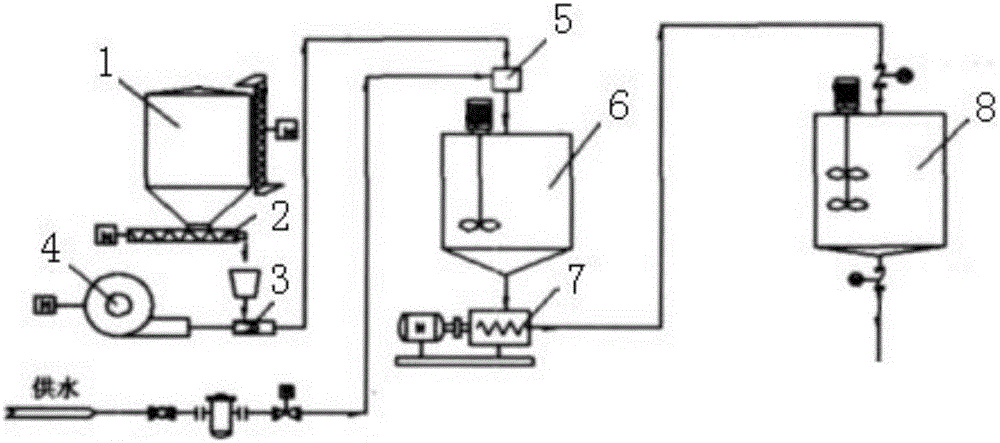

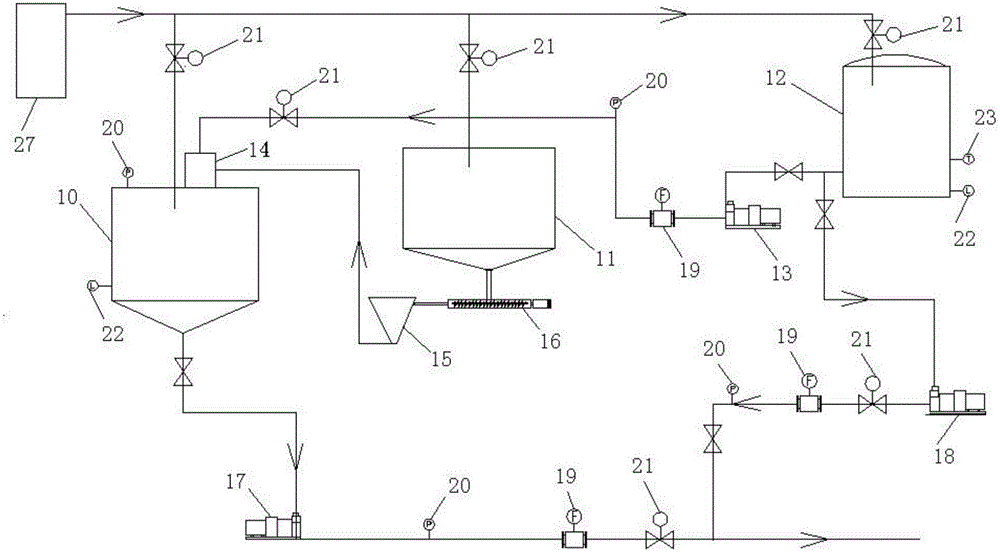

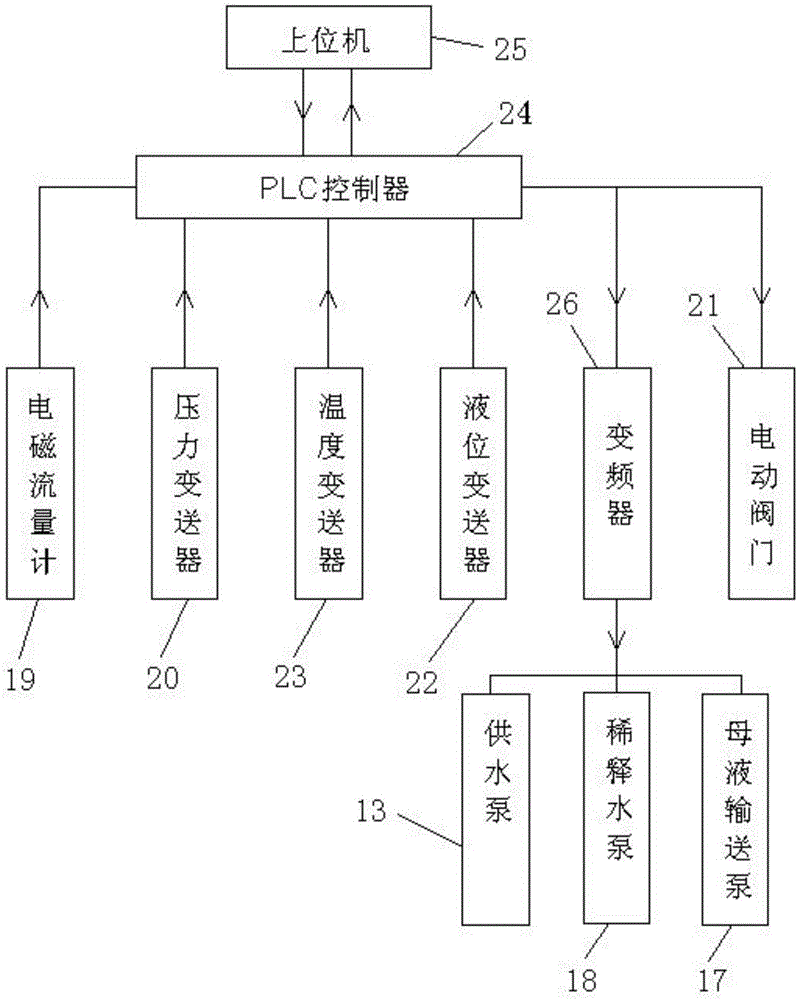

[0022] The technical scheme of the present invention will be introduced below in conjunction with the accompanying drawings.

[0023] Such as figure 2 As shown, the powdery polymer rapid dispersion and dilution system of offshore or alpine or fault block oil fields of the present invention includes a water supply tank 12, a dry powder tank 11 and a buffer tank 10, the water supply tank 12 is used for storing injection water, and the dry powder tank 11 is used for storing Powdery polymer, buffer tank 10 is used for temporarily storing the mother liquor after injecting water and powdery polymer mixing, water supply tank 12, dry powder tank 11 and buffer tank 10 are all connected with nitrogen source 27 by pipeline, and water supply tank 12 and An electric valve 21 is provided on the pipeline between the nitrogen source 27 , an electric valve 21 is provided on the pipeline between the dry powder tank 11 and the nitrogen source 27 , and an electric valve 21 is provided on the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com