Production method for quantum dot solid powder

A technology of solid powder and production method, applied in the field of quantum dots, can solve problems such as destructiveness and destroy the physical and chemical properties of quantum dots, and achieve the effects of excellent performance, uniform size, and overcoming fine particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

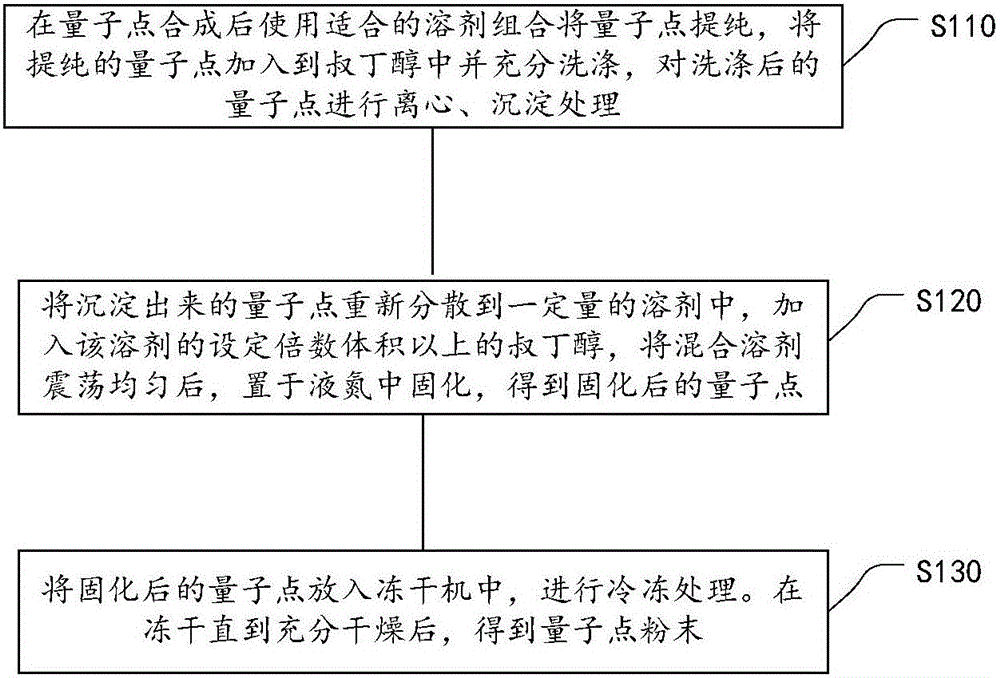

[0028] The processing flow of a quantum dot desolventization process method provided by the embodiment of the present invention is as follows: figure 1 As shown, the following processing steps are included:

[0029] Step S110, after the quantum dots are synthesized, use a suitable solvent combination to purify the quantum dots, add the purified quantum dots to tert-butanol and wash them thoroughly, and perform centrifugation and precipitation treatment on the washed quantum dots.

[0030] The aforementioned synthesis of quantum dots includes, but is not limited to, quantum dots synthesized in water phase or oil phase.

[0031] The choice of solvent is dictated by the surface ligands of the bound quantum dots. For quantum dots synthesized in oil phase, the solvent includes toluene, chloroform, n-hexane and / or cyclohexane. For quantum dots synthesized in water phase, the solvent includes water, ethanol, isopropanol, butanol and / or ethyl acetate.

[0032] Step S120, redispersi...

Embodiment 2

[0038] For some quantum dots synthesized in oil phase such as CuInZnS quantum dots, after synthesis and purification, a part of quantum dots is dried by traditional process, and another part of quantum dots is dried by the process method of the present invention: redisperse with 0.5mL of chloroform, then add 50mL of tert-butanol was used to precipitate the quantum dots, solidified with liquid nitrogen and placed in a lyophilizer for lyophilization.

[0039] For quantum dots synthesized in aqueous phase such as CdSe, after synthesis and purification, a part of the quantum dots is dried by the traditional process, and another part of the quantum dots is dried by the process of the present invention; redispersed with 0.5mL of water, and then added 500mL of tert-butanol When the quantum dots are precipitated, they are solidified with liquid nitrogen and placed in a lyophilizer.

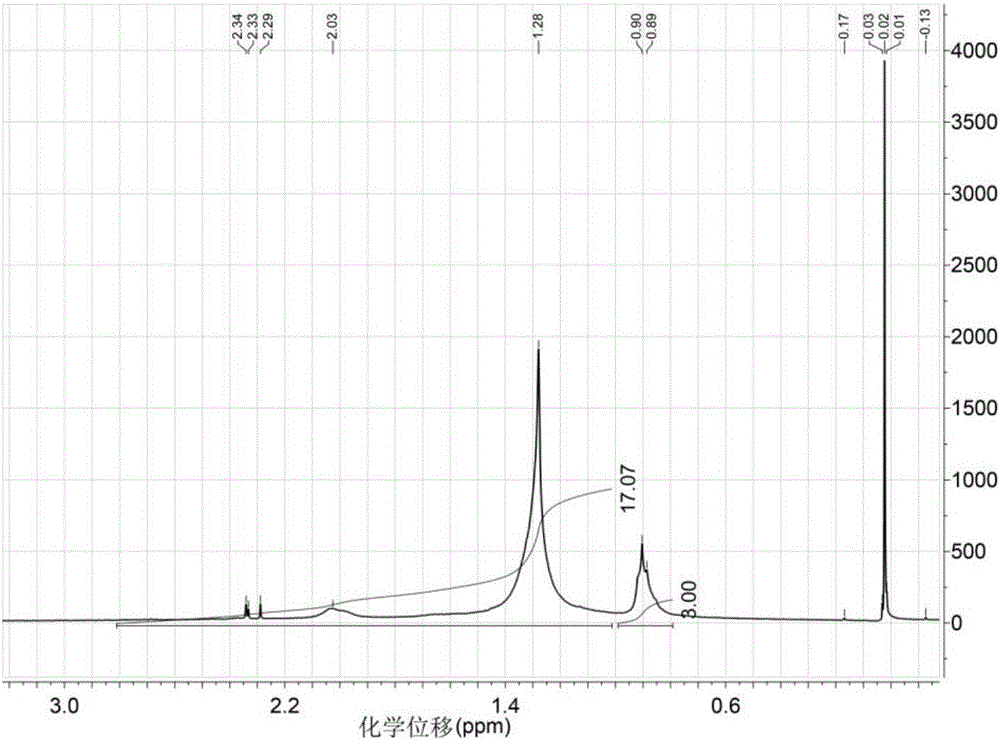

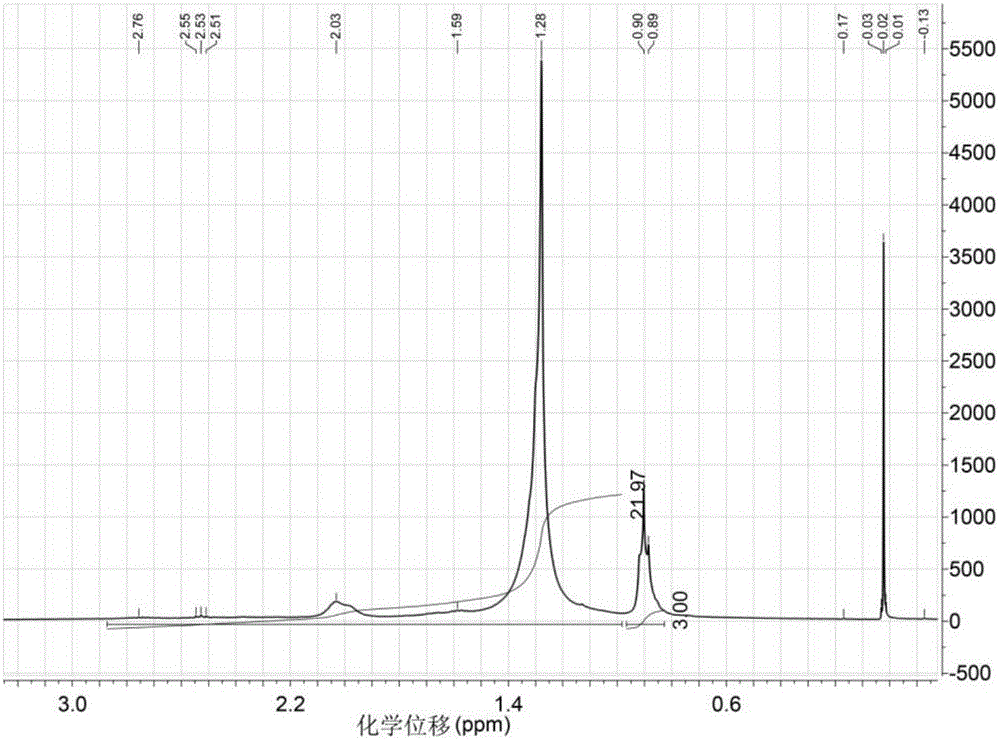

[0040] figure 2 , 3 are the CuInZnS quantum dots of the oil phase synthesis that are made by the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com