Elastic wind power coupler with stepless speed change and on-off functions

A continuously variable speed and coupling technology, applied in elastic couplings, clutches, couplings, etc., can solve the problems of rotational speed, torque fluctuations, shortened gearbox life, gearbox failures, etc., to achieve constant torque , Excellent cost performance, the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

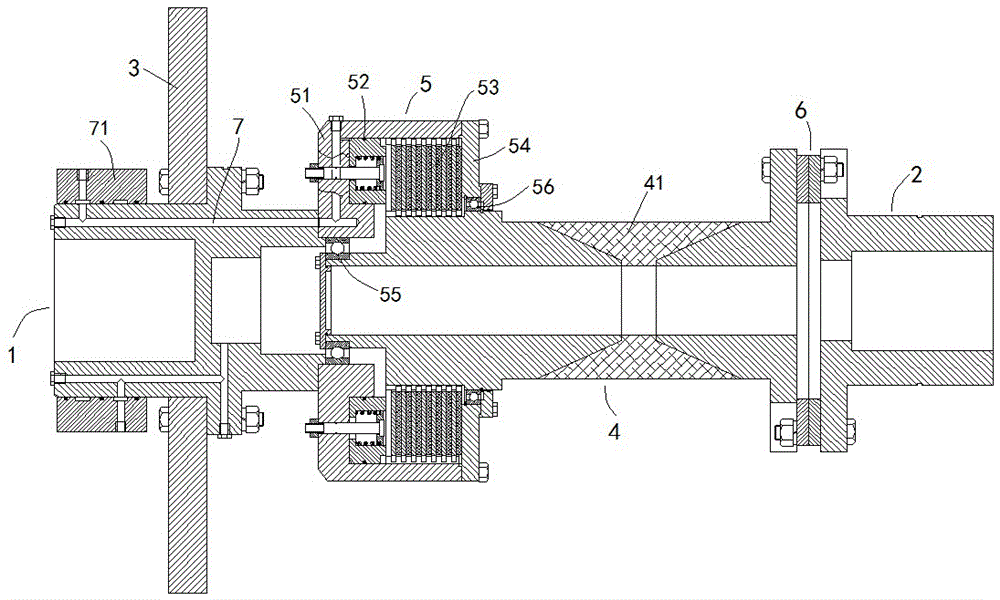

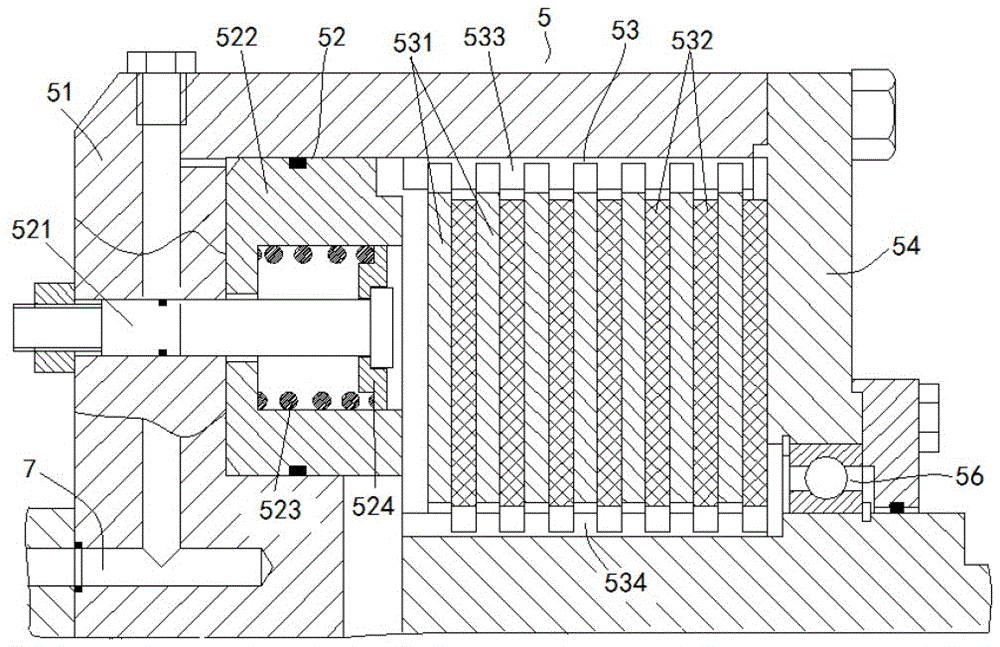

[0032] Such as figure 1 As shown, in one embodiment of the present invention, an elastic wind power coupling with continuously variable speed and clutch functions, its structure is: the first flange 1 is connected to the intermediate shaft 4 of the coupling through the governor 5 , the second flange 2 is connected with the coupling intermediate shaft 4 through the diaphragm coupling 6 . In use, the first flange 1 is connected to the output shaft of the gearbox through a flat key, and the second flange 2 is connected to the motor shaft without a key. The first flange 1 is also connected to a brake pad 3 .

[0033] Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com