A system and method for evaluating the life of a boiler heating surface

A technology of life assessment and heating surface, applied in the testing, instruments, measuring devices of machine/structural components, etc., can solve the problems of unverifiable, unable to predict the remaining life of the equipment, and no control strategy for extending life, etc., to extend the life. , to ensure the effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. Contents Some non-essential improvements and adjustments have been made to this application.

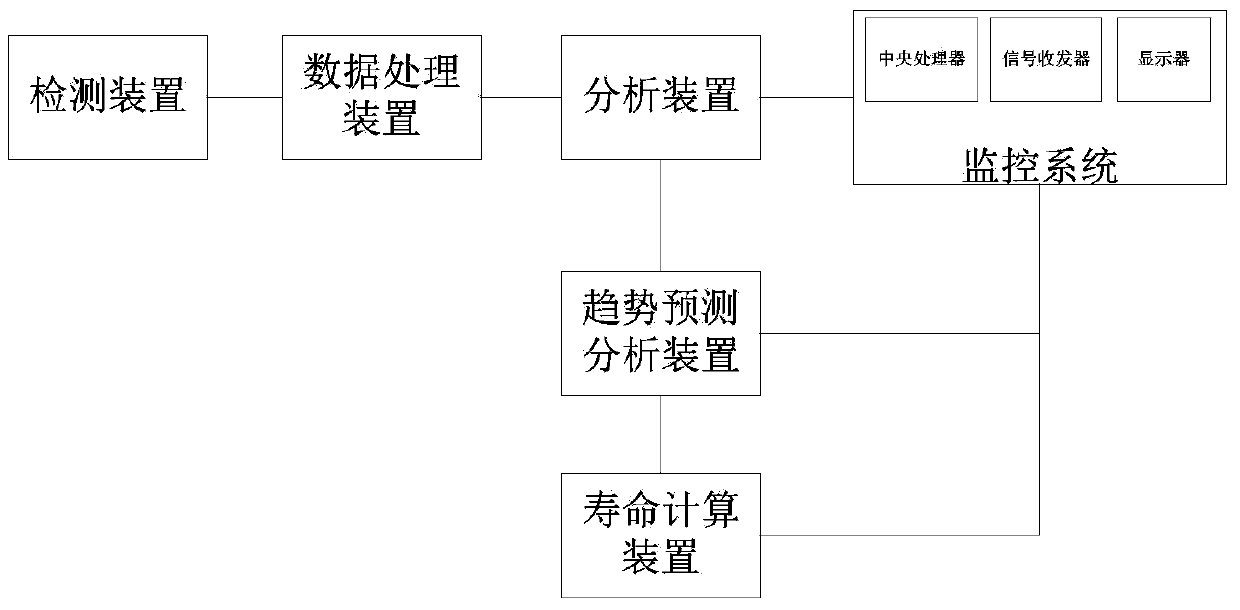

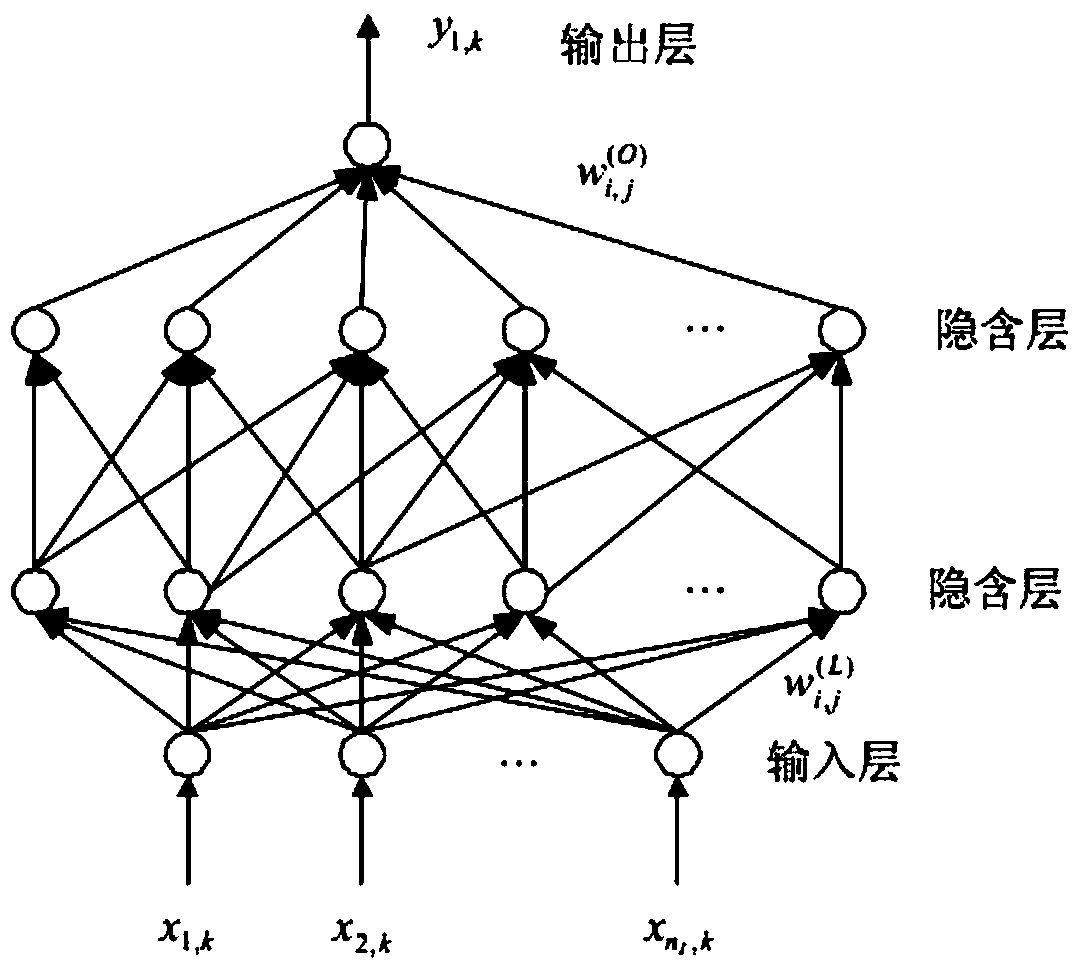

[0030] Such as figure 1 As shown, this application proposes a boiler heating surface life evaluation system, including a detection device, a data processing device, an analysis device, and a monitoring system. The detection device is connected to a data processing device and an analysis device in sequence, and the analysis device analyzes the data. , and sent to the monitoring system; also includes a trend prediction analysis device, a life calculation device, the trend prediction analysis device uses the fuzzy neural network method to perform future operation trend analysis b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com