Industrial robot product assembling method based on internet of things

An industrial robot and assembly method technology, applied in the direction of instruments, network interconnection, comprehensive factory control, etc., can solve problems such as the inability to meet the production needs of multiple varieties and small batches, to improve production efficiency and resource utilization, and enhance core competition. force, use reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific examples.

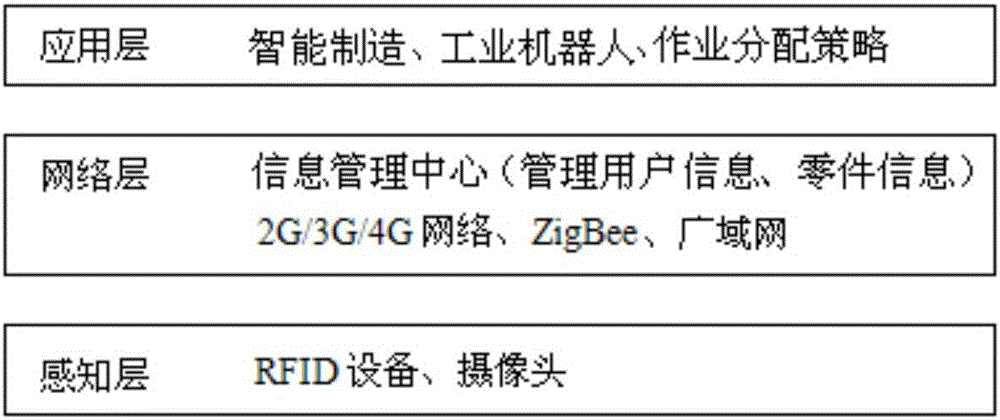

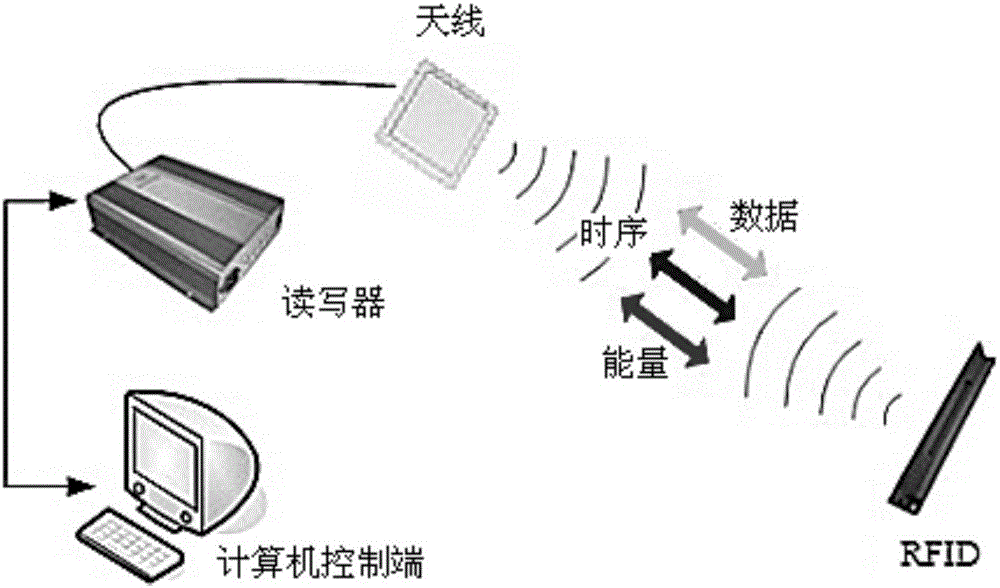

[0046] The method for assembling industrial robot products based on the Internet of Things in the present invention specifically combines RFID technology, mobile communication technology and embedded technology to build an Internet of Things and its communication gateway, and through its perception layer, the product parts information to be assembled Access to the Internet to achieve information acquisition, transmission, and interaction among various elements in the manufacturing process; then integrate production resources, customer product requirements, and product part information to build an information management center that treats assembled product part information, customer product information, etc. Manage demand information, and generate job allocation algorithms for product part assembly based on these information and data, and rationally allocate production resources...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com