Compensation adjusting method for main steam pressure of thermal power generating unit

A technology of main steam pressure and main steam pressure, applied in the field of control, can solve the problems of difficult control of large inertia and large delay characteristics, fluctuation of superheated steam temperature, fluctuation of boiler fuel quantity, etc. Improve the effect of control quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

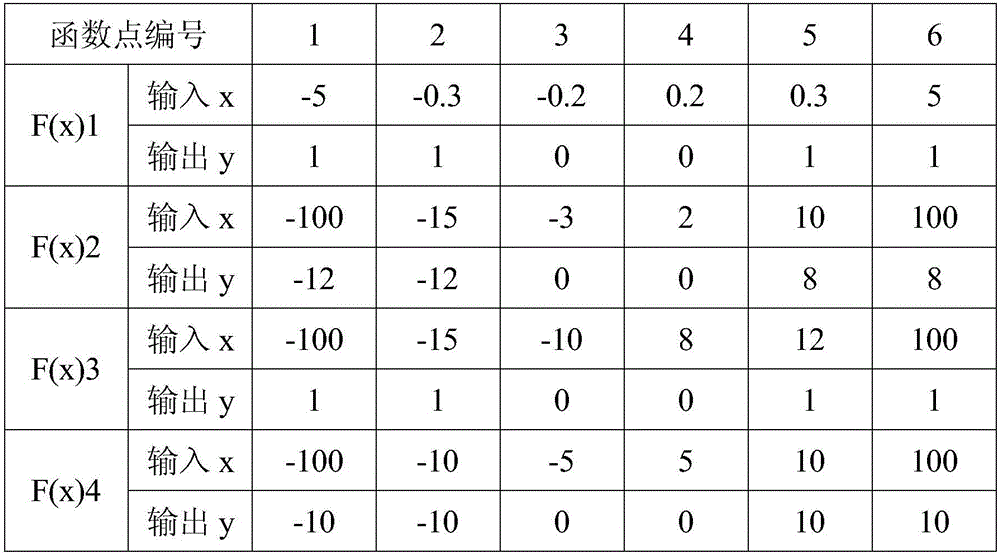

[0026] The present invention will be further described below in conjunction with accompanying drawing.

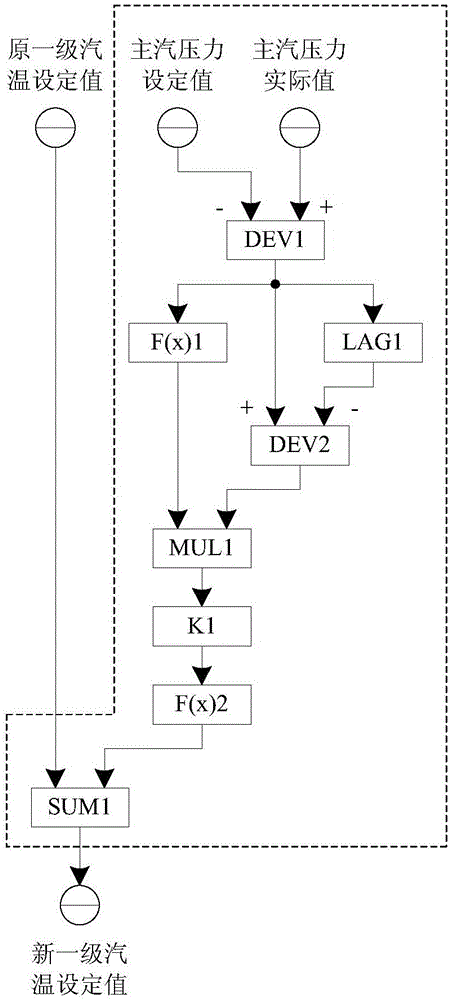

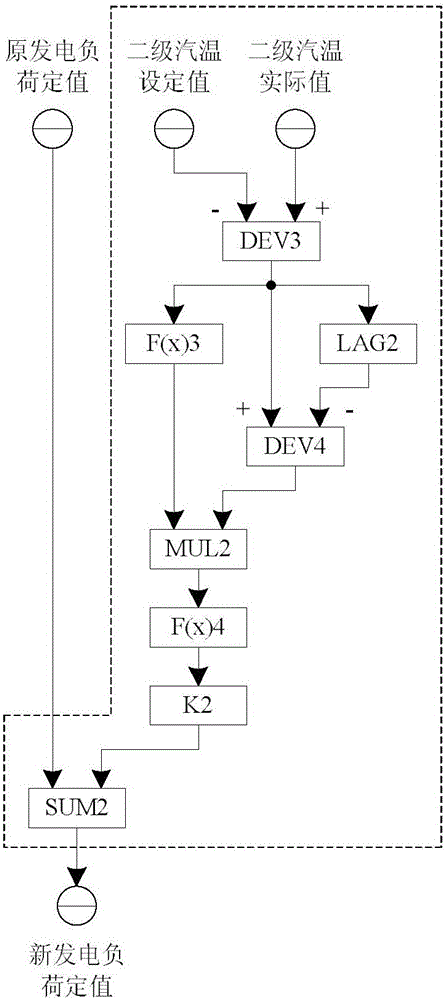

[0027] Aiming at the problem of large fluctuations in main steam pressure and superheated steam temperature caused by frequent changes in power generation load of thermal power units, the present invention proposes a method for compensating and adjusting main steam pressure by using the desuperheating water flow of the first-stage superheater.

[0028] From the design analysis, the control target of the primary superheated steam temperature control system is not unique, it only needs to maintain the primary superheated steam temperature within a certain range, so it has the conditions to compensate and adjust the main steam pressure. After the superheater desuperheating water is injected, it can quickly affect the main steam pressure, and the rapidity of the compensation adjustment process is obviously better than that of the fuel quantity adjustment. At the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com