Spherical fuel element disintegration device

A spherical fuel element and electrolytic cell technology, which is applied in nuclear engineering, radioactive purification, etc., can solve the problems of being unsuitable for shielding rooms and unable to obtain the position information of coated particles, etc., and achieves easy remote control, avoiding interference and pollution, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

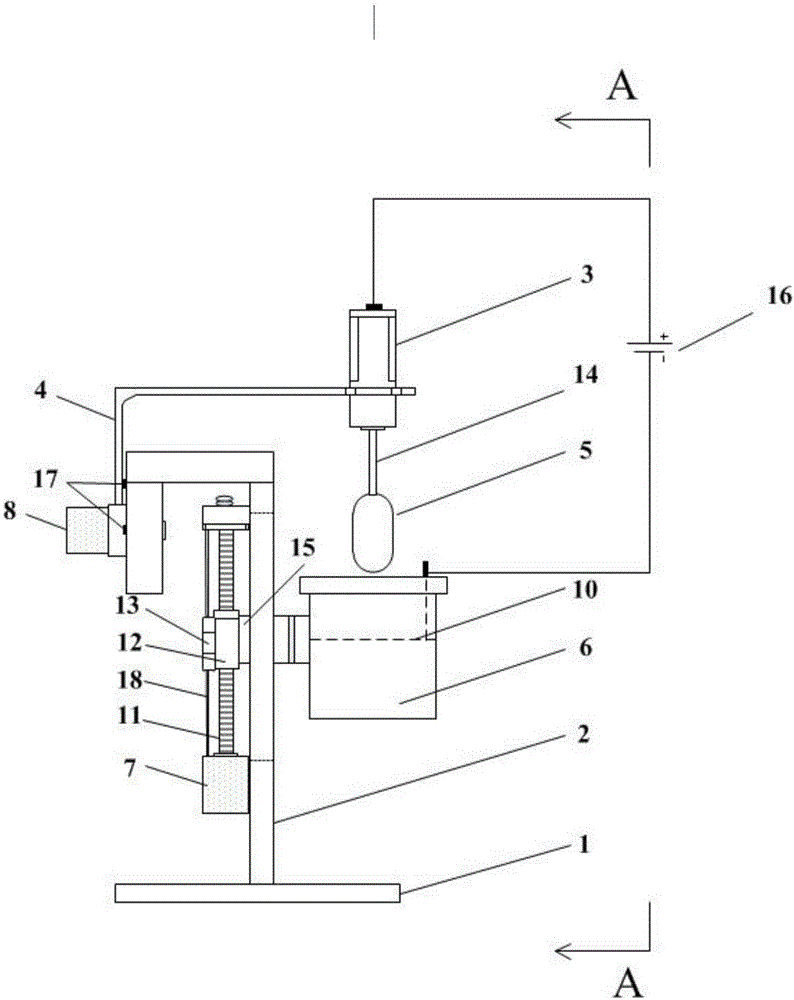

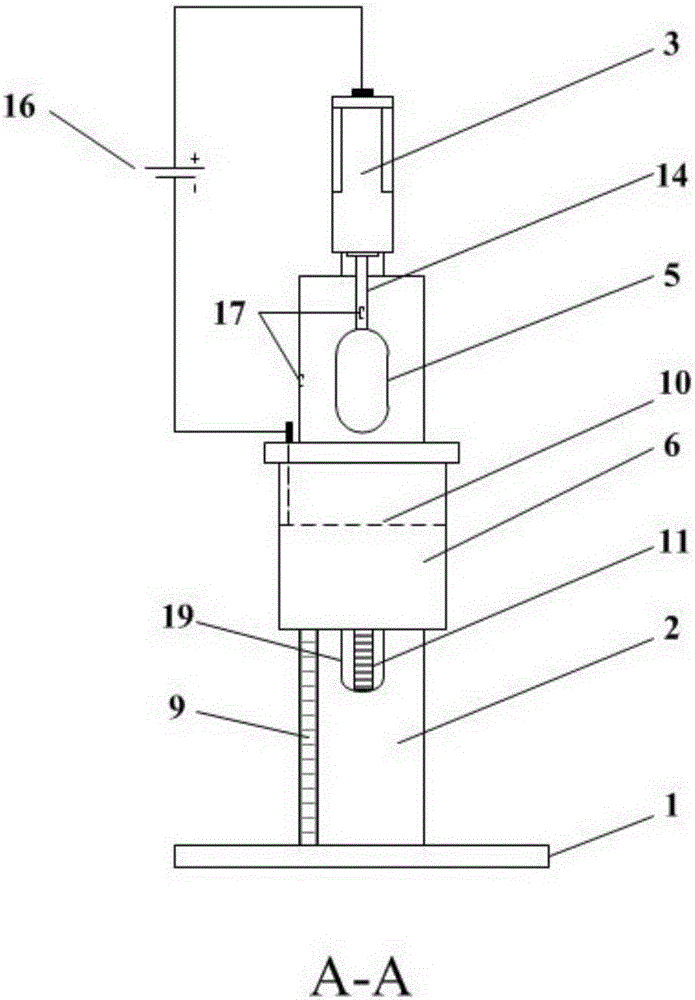

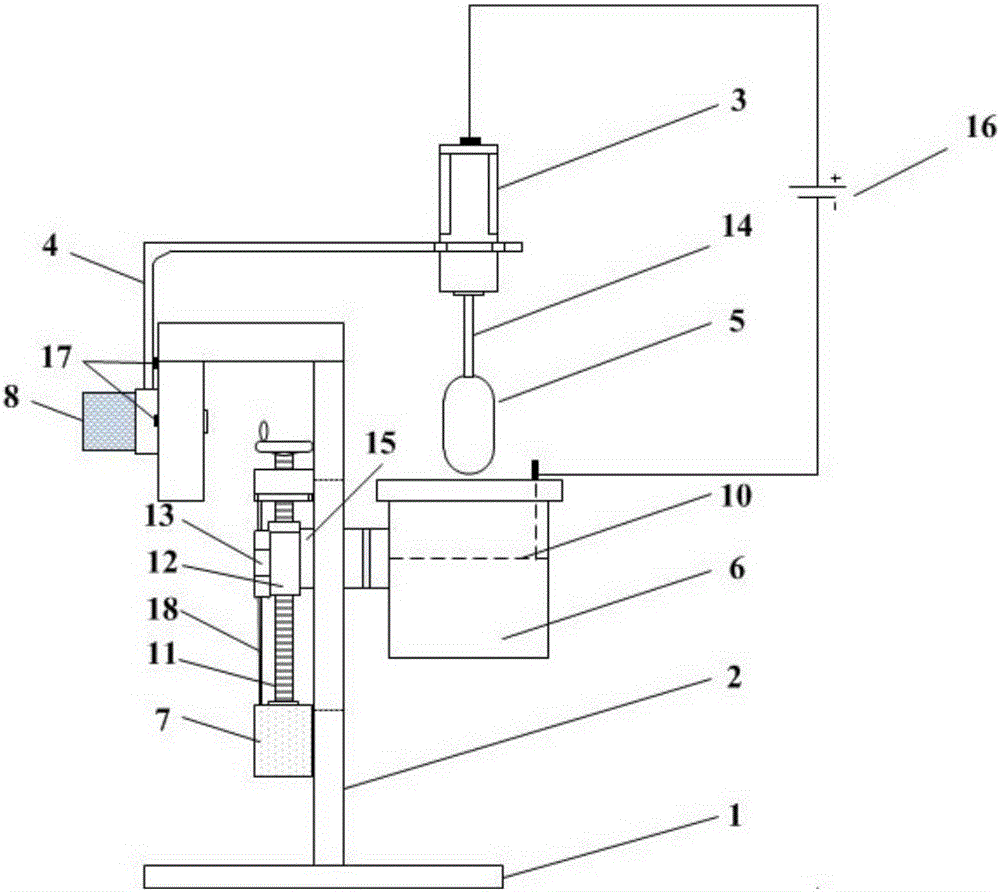

[0014] The spherical fuel element dismantling device that the present invention proposes, its structure is as follows figure 1 As shown, it includes a base 1, a door-shaped column 2, a rotating motor 3, a lifting module 7, a rotating module 8, a cantilever bracket 4, an electrolytic cell 6, a screw motor 7, a scale 9, a mesh cathode 10, a ball screw 11, Screw nut 12, sliding seat 13, fixture 14, connecting frame 15, DC power supply 16, limit switch 17, guide rail 18, opening groove 19. One side of the door-shaped column 2 is fixed on the base 1, and the column has an open groove 19, and the rotating module 8 is relatively fixed with the other side of the door-shaped column 2. The short arm of the cantilever bracket 4 is linked with the output shaft of the rotary module 8 . Rotating motor 3 is fixed on the end of the long arm of cantilever support 4 . The lifting module 7 is fixed on the upper or lower part of one side of the door column 2 . The electrolytic cell 6 is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com