Polypropylene resin composition having excellent whitening resistance and impact resistance

A technology of polypropylene resin and composition, which is applied in the field of polypropylene resin composition with excellent whitening resistance and impact resistance, can solve the problems of poor shrinkage, lower processing performance, high cost of manufacturing, etc., and achieve excellent results, durability Excellent effect of whitening and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (a) First polymerization stage

[0054] In the presence of a catalyst produced by reacting a titanium compound with a phthalate-based internal donor on a dialkoxymagnesium carrier, ethylene, propylene, and 1-butene are simultaneously injected to perform bulk polymerization, and The ethylene-propylene-butene random copolymer was produced by copolymerizing so that ethylene contained 2 weight% and 1-butene contained 6 weight% in the produced copolymer.

[0055] (b) Second polymerization stage

[0056] In the presence of the ethylene-propylene-butene random copolymer produced through the first polymerization stage, additional ethylene and propylene are added so that the ethylene content of the ethylene-propylene block copolymer becomes the weight percent 32% was produced, and the amount of polymerization was adjusted so that the ethylene-propylene-butene random copolymer became 88% by weight, the ethylene-propylene block copolymer became 12% by weight, and the intrinsic vi...

Embodiment 2 to 7

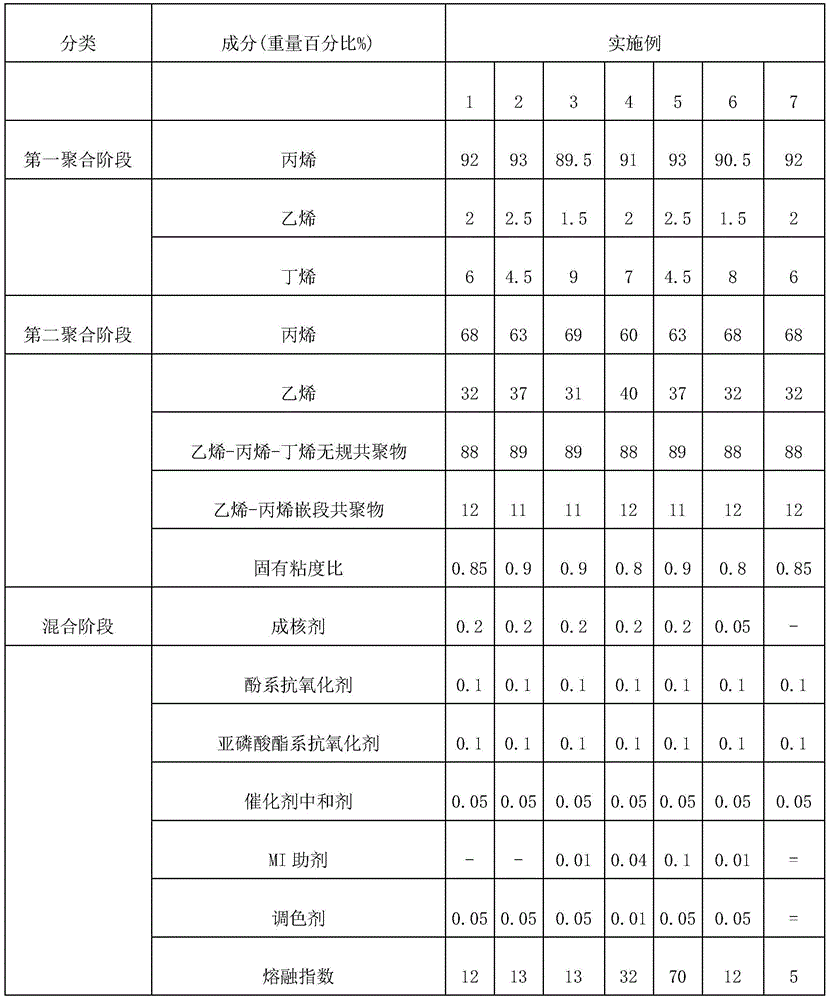

[0060] Implement in the same manner as described Example 1, and the content of each component is shown in the following table 1 (however, the MI auxiliary agent uses PK010 (POLYMODIFIER), and the melting process before adding the MI auxiliary agent is 4 ~ 5g / min).

[0061] 【Table 1】

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com