A kind of cultivation method of citrus

A cultivation method and citrus technology, applied in the field of citrus cultivation, can solve the problems of inability to realize factory production, low land utilization rate, and low input-output ratio, so as to increase effective absorption of roots and photosynthesis, and improve land utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

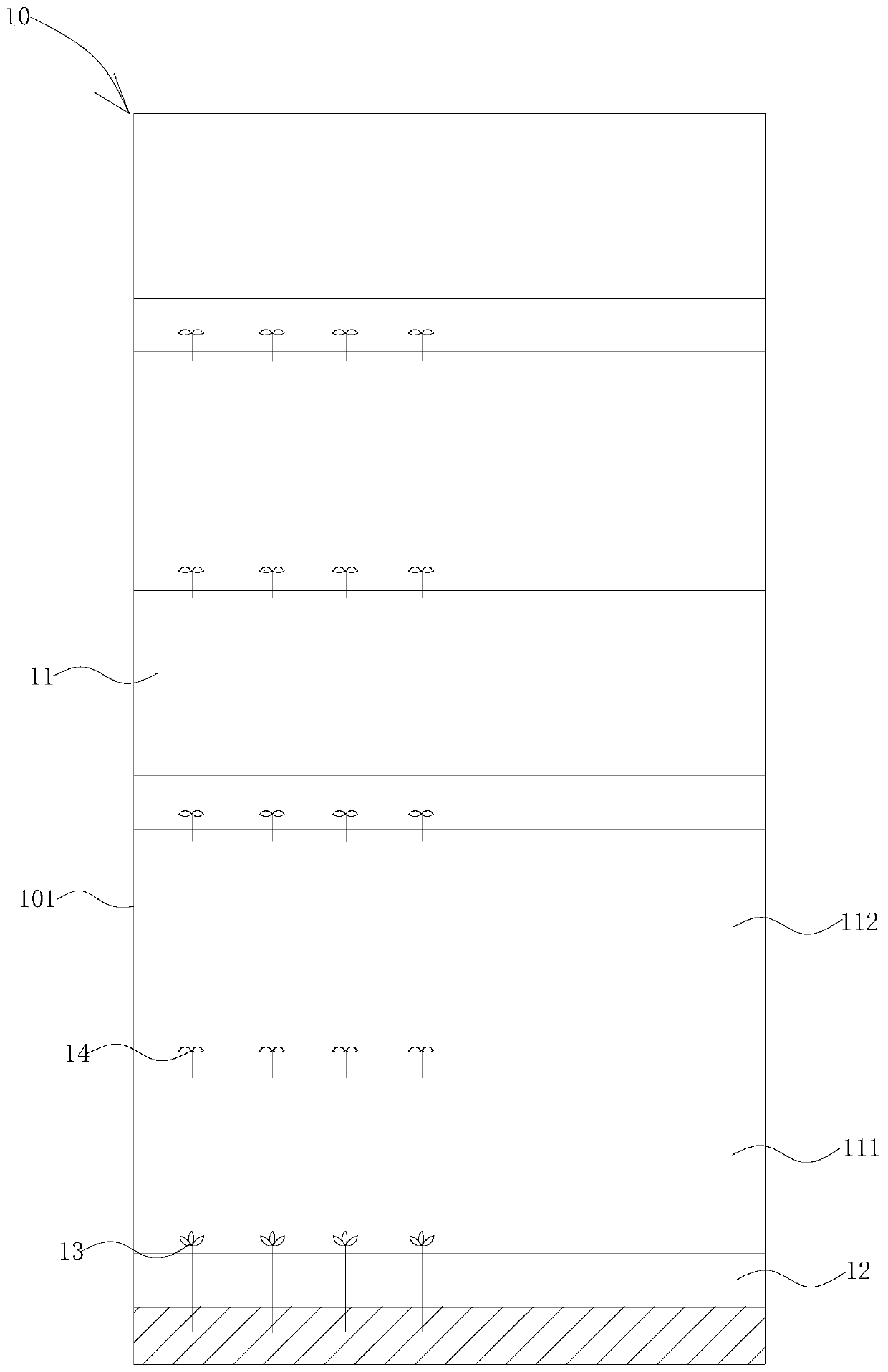

[0051] see figure 1 and figure 2 , first make the planting wall 10, set the wall skeleton 101 on the land, and set a plurality of matrix grooves 11 and a plurality of spacer gaps 12 in the vertical direction on the wall skeleton 101 to form the planting wall 10, and the plurality of matrix grooves 11 Alternately arranged with the interval band gaps 12, five matrix grooves 11 and five interval band gaps 12 are preferably set in this embodiment, the height of each matrix groove 11 is 0.8m, and the height of the interval band gaps 12 is 0.2m, The wall of matrix tank 11 is built with bricks, wherein the side wall of matrix tank 11 is provided with movable plate, and the height of movable plate is 0.4m, is convenient to replace root system and matrix. Matrix groove 11 and spacer band gap 12 form planting wall 10; Multiple planting walls 10 are set in the shed room, 1.6m is spaced between each planting wall 10, and lime water is coated on the sidewall of matrix groove 11, and in ...

Embodiment 2

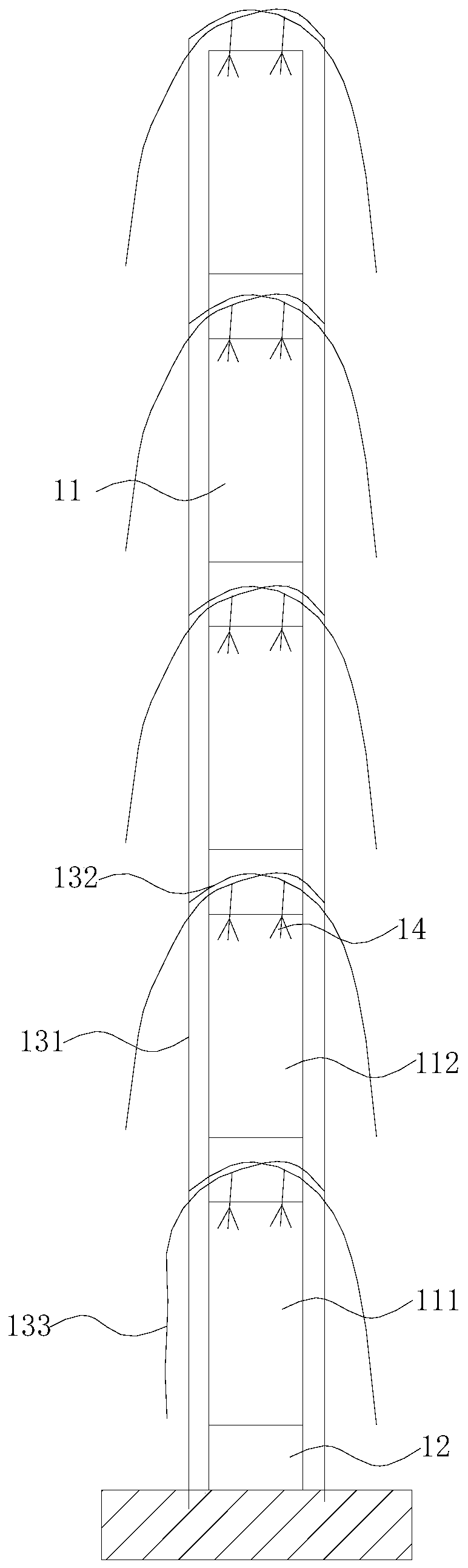

[0059] see image 3 , first make the planting wall 10, set the wall skeleton 101 on the land, and set a plurality of matrix grooves 11 and a plurality of spacer gaps 12 in the vertical direction on the wall skeleton 101 to form the planting wall 10, and the plurality of matrix grooves 11 Alternately arranged with the interval band gaps 12, in this embodiment, four matrix grooves 11 and four interval band gaps 12 are preferably set, the height of each matrix groove 11 is 1.1m, and the height of the interval band gaps 12 is 0.3m, The wall of matrix tank 11 is built with bricks, wherein the side wall of matrix tank 11 is provided with movable plate, and the height of movable plate is 0.3m, is convenient to replace root system and matrix. Matrix groove 11 and spacer band gap 12 form planting wall 10; Multiple planting walls 10 are set in the shed room, 1.5m is spaced between each planting wall 10, and lime water is coated on the sidewall of matrix groove 11, and in Lay reflective...

Embodiment 3

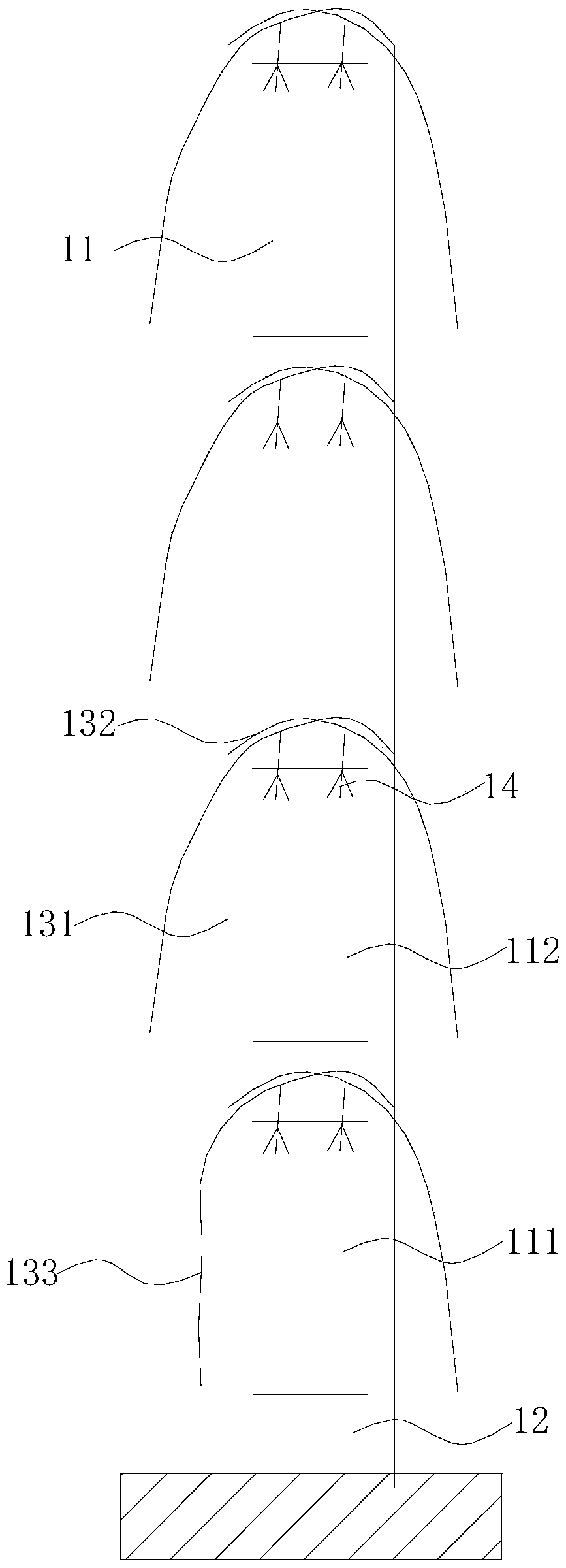

[0067] see Figure 4 , first make the planting wall 10, set the wall skeleton 101 on the land, and set a plurality of matrix grooves 11 and a plurality of spacer gaps 12 in the vertical direction on the wall skeleton 101 to form the planting wall 10, and the plurality of matrix grooves 11 Alternately arranged with the spacer band gaps 12, seven matrix grooves 11 and seven spacer band gaps 12 are preferably set in this embodiment, the height of each matrix groove 11 is 0.5m, and the height of the spacer band gaps 12 is 0.1m, The wall of matrix tank 11 is built with bricks, wherein the side wall of matrix tank 11 is provided with movable plate, and the height of movable plate is 0.3m, is convenient to replace root system and matrix. Matrix groove 11 and spacer band gap 12 form planting wall 10; Multiple planting walls 10 are set in the shed room, 1.4m is spaced between each planting wall 10, and lime water is coated on the sidewall of matrix groove 11, and in Lay reflective fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com