Batch circular grain dryer

A grain dryer, batch technology, applied in the direction of saving seeds by drying, can solve the problems of constant feeding and discharging operations, waste of heat, difficult maintenance, etc., to reduce maintenance costs, reduce waist burst rate, dry area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] The following are specific embodiments of the present invention.

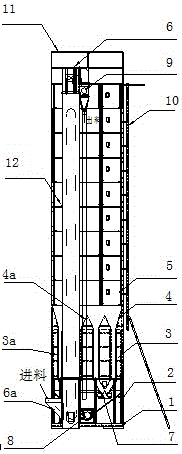

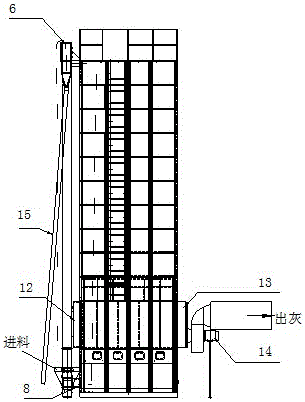

[0025] as attached figure 1 As shown, this embodiment provides a batch type circulating grain dryer, including a base 1 . The bottom layer 2, the drying layer 3, the diversion layer 4 and the storage layer 5 are sequentially arranged on the base from bottom to top, and the bottom layer 2, the drying layer 3, the diversion layer 4 and the storage layer 5 are connected to each other; the base 1 is also connected with the lower auger 8 and the hoist 6; the lower side of the hoist is provided with a feed hopper 6a, the upper part of the hoist 6 is connected with the upper auger 9, and the upper auger 9 is connected with the storage layer 5 is connected; the drying layer 4 is communicated with the grain dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com