A kind of supported tricobalt tetroxide catalyst and its preparation method and application

A technology of cobalt tetroxide catalyst and cobalt tetroxide, which is used in catalyst activation/preparation, cobalt oxide/cobalt hydroxide, physical/chemical process catalyst, etc., can solve the problem of catalyst activity decline, temperature can not meet the exhaust gas of natural gas engine, lack of precious metals and carriers problems of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

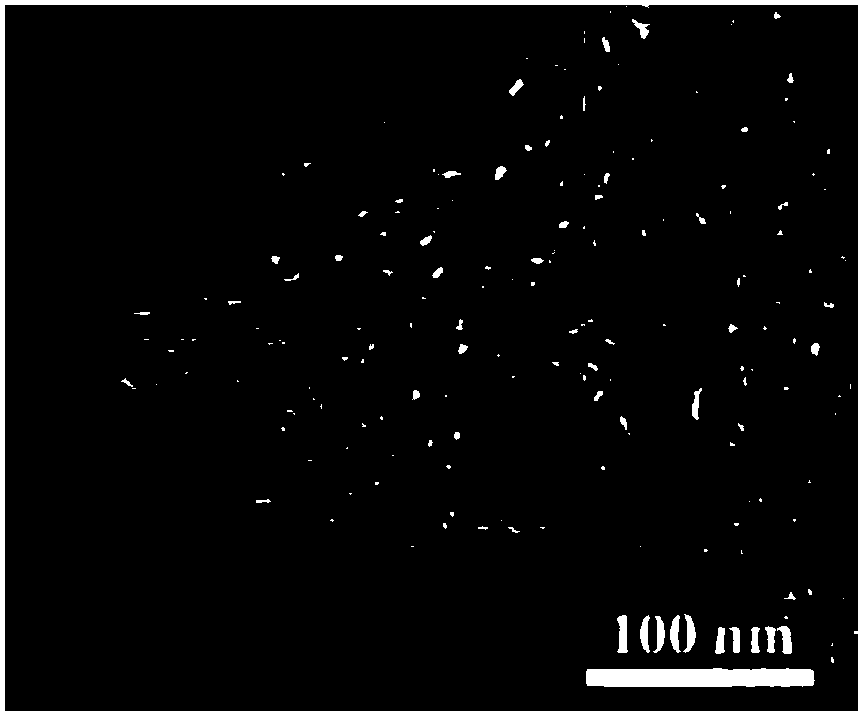

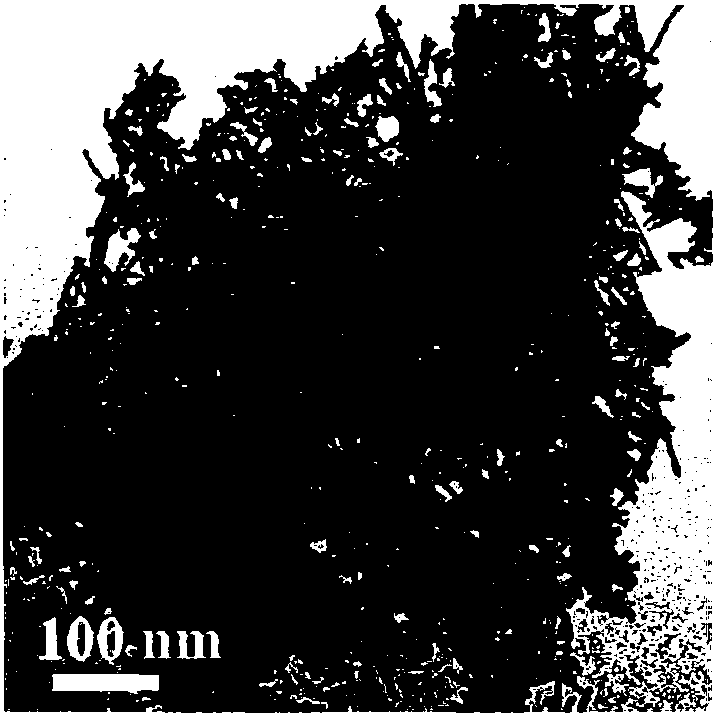

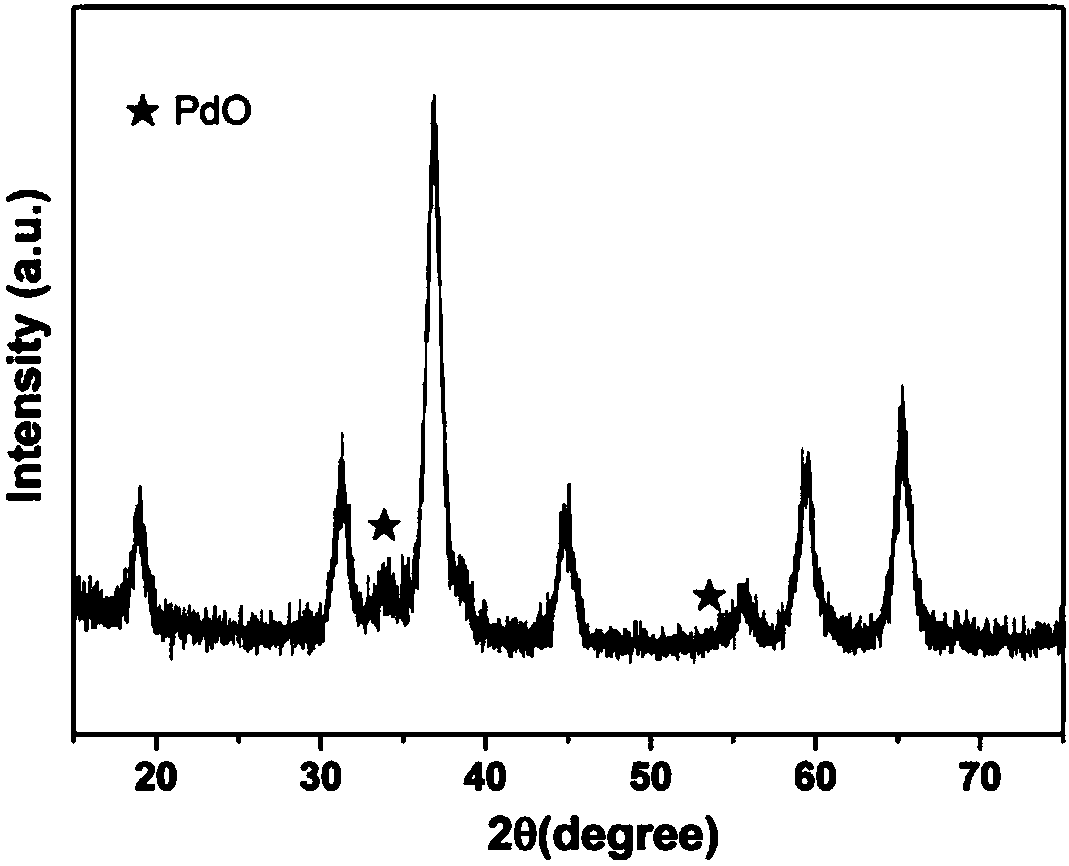

[0044] 3%Pd-Co 3 o 4 Nanorods (3% refers to the quality of noble metal elements and noble metal elements and Co 3 o 4 The ratio of the total mass, the following examples are defined the same): Weigh 10mmol cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) Dissolve in 30mL ethylene glycol, gradually heat to 80°C, then add 0.2mol / L Na in 100mL deionized water 2 CO 3 aqueous solution. After stirring vigorously for 10 min, 20 mL of 0.0628 g Pd(NO 3 ) 2 solution, and continuously feed N into it 2 Ageing. After reacting for one hour, it was transferred to a high-pressure reactor, heated in water at 160°C for 3h, cooled to room temperature, centrifuged and washed with deionized water, and then vacuum-dried at 60°C for 12h to obtain a catalyst precursor. TEM image See Figure 1a , and then fired at 300°C for 4h. Finally, the calcined body is ground into fine powder, extruded in a mold under a pressure of 40kN, crushed and sieved to obtain catalyst particles with a partic...

Embodiment 2

[0046] 1%Pd-Co 3 o 4 Nanorods: Weigh 10mmol cobalt nitrate and dissolve it in 25mL ethylene glycol, gradually heat to 80°C, then add 0.1mol / L NaHCO dissolved in 100mL deionized water 3 aqueous solution. After stirring vigorously for 10 min, 15 mL of 0.021 g Pd(NO 3 ) 2 solution, and continuously feed N into it 2 Ageing. After reacting for 1h, transfer it to a high-pressure reactor, heat it in water at 160°C for 3h, cool to room temperature, centrifuge and wash with deionized water, dry it in vacuum at 60°C for 12h, and then bake it at 400°C for 4h. Finally, the calcined body is ground into fine powder, extruded in a mold under a pressure of 40kN, crushed and sieved to obtain catalyst particles with a particle size of 40-60 mesh. The catalytic reaction conditions are: the temperature of the catalytic reaction is 150-450°C, the pressure is normal pressure; the total flow rate of the reaction is 50mL / min, and the flow rate of these three gases is higher than that of CH 4 :...

Embodiment 3

[0048] 5%Pd-Co 3 o 4 Nanorods: Weigh 5mmol cobalt chloride and dissolve it in 20mL ethylene glycol, gradually heat to 70°C, then add 0.3mol / L NH2 dissolved in 50mL deionized water 4 HCO 3 aqueous solution. After stirring vigorously for 10 min, 10 mL of 0.105 g Pd(NO 3 ) 2 solution, and continuously feed N into it 2 Ageing. After reacting for 1h, transfer it to a high-pressure reactor, heat it in water at 160°C for 2h, cool to room temperature, centrifuge and wash with deionized water, dry it in vacuum at 50°C for 10h, and finally bake it at 300°C for 3h. The calcined body is ground into fine powder, extruded in a mold under a pressure of 40kN, crushed and sieved to obtain catalyst particles with a particle size of 40-60 mesh. The catalytic reaction conditions are: the temperature of the catalytic reaction is 150-450°C, the pressure is normal pressure; the total flow rate of the reaction is 100mL / min, and the flow rate of these three gases is higher than that of CH 4 :O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com