A four-way valve body casting

A technology of four-way valve and valve body, which is applied in casting molds, valve details, multi-way valves, etc., can solve problems such as easy cracks, difficult manufacturing, and casting pore defects, so as to achieve smooth exhaust and high tensile strength , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

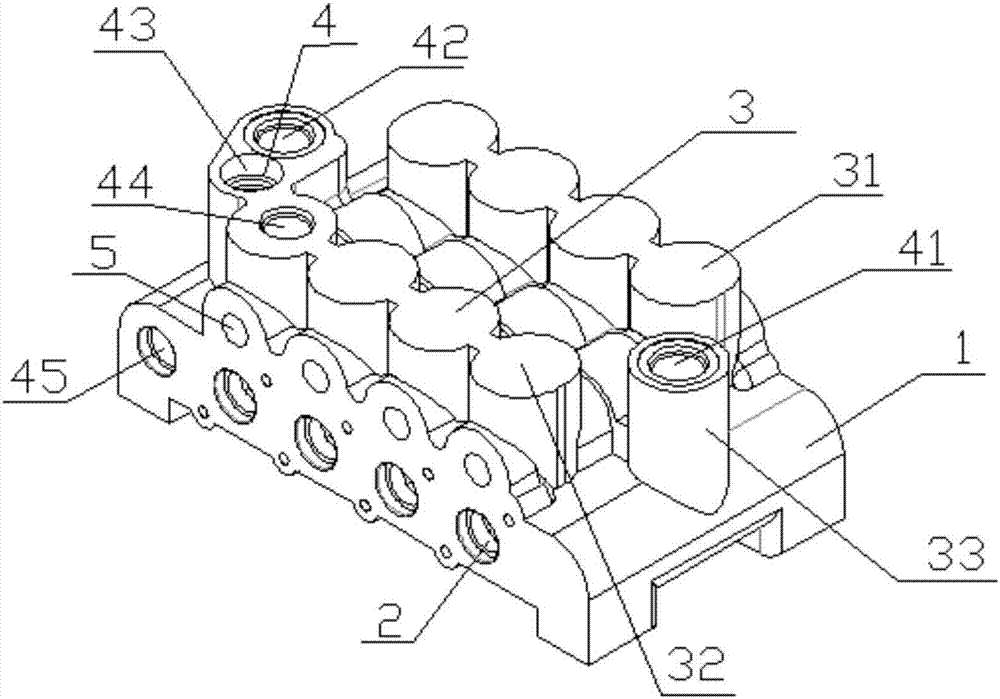

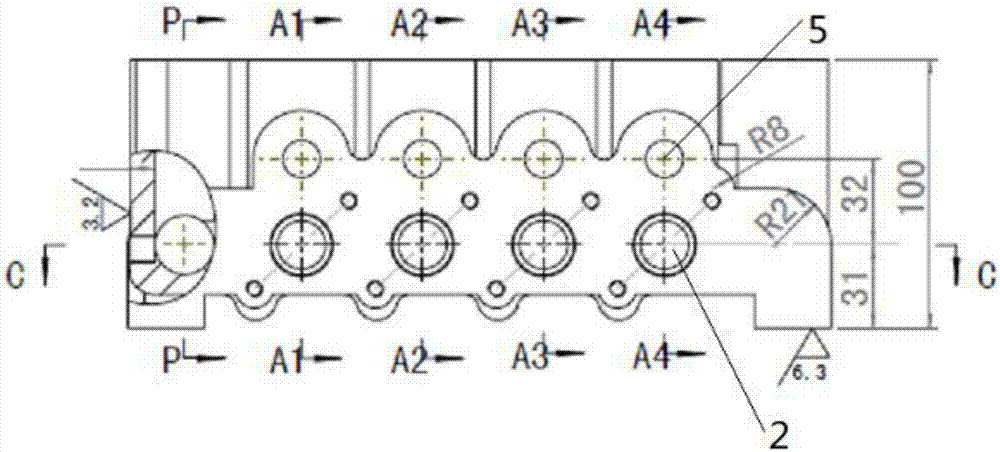

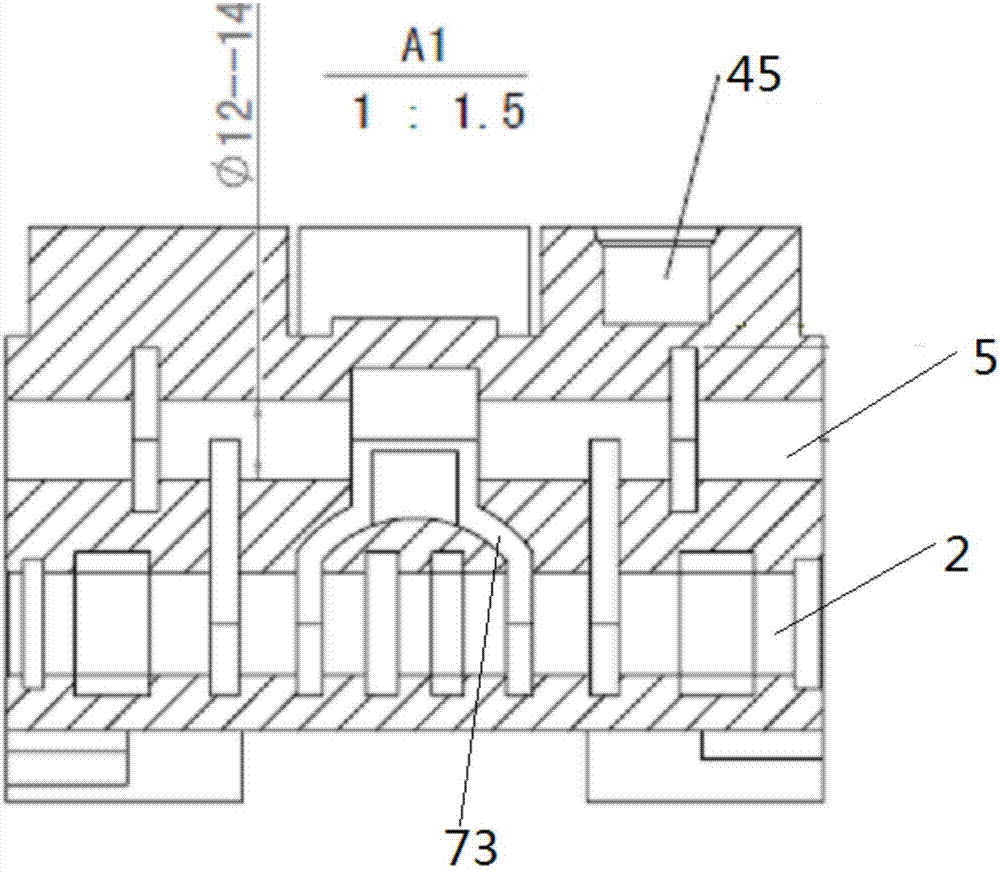

[0032] see Figure 1-6 . Such as Figure 1-6 As shown, the present invention discloses a valve body casting for a quadruple valve, including a valve body 1, a transverse flow channel 6, a longitudinal flow channel and a flow channel opening 4, the valve body 1 is in the shape of a cuboid, and the longitudinal flow channel includes a first A longitudinal flow channel 2 and a second longitudinal flow channel 5, the first longitudinal flow channel 2 and the second longitudinal flow channel 5 are both tubular structures, and the cavity 3 is vertically arranged above the second longitudinal flow channel 5 , the lower ends of the cavity 3 are openings, the cavity 3 includes a first cavity 31, a second cavity 32 and a third cavity 33, the first cavity 31 consists of four cylinders of the same size The body is connected transversely along the straight line where the center of the bottom surface is located. The second cavity 32 is formed by connecting six cylinders. The centers of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com