Workpiece jig with adjustable clamping angle

A workpiece and angle technology, applied in the field of processing fixtures, can solve the problems of inconvenient operation, reduced processing efficiency, and the clamping device cannot adjust the clamping angle, etc., and achieves the effect of convenient angle adjustment and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

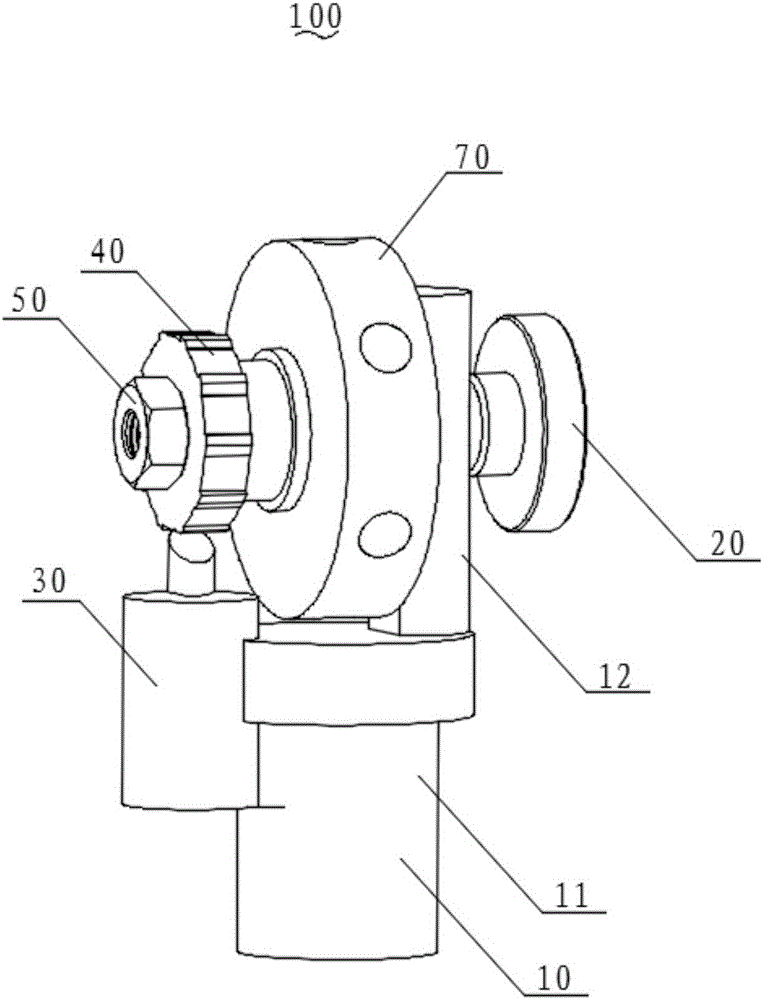

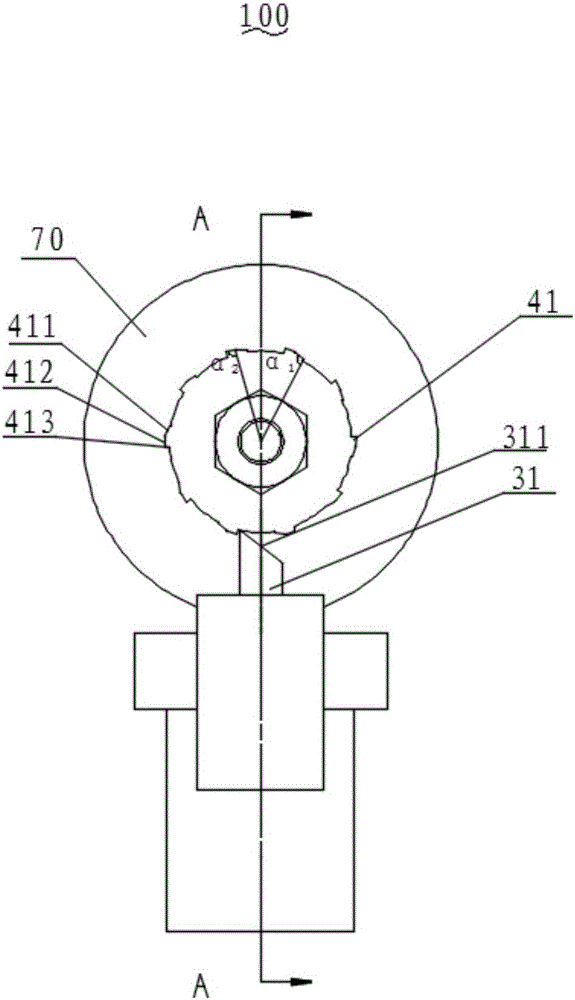

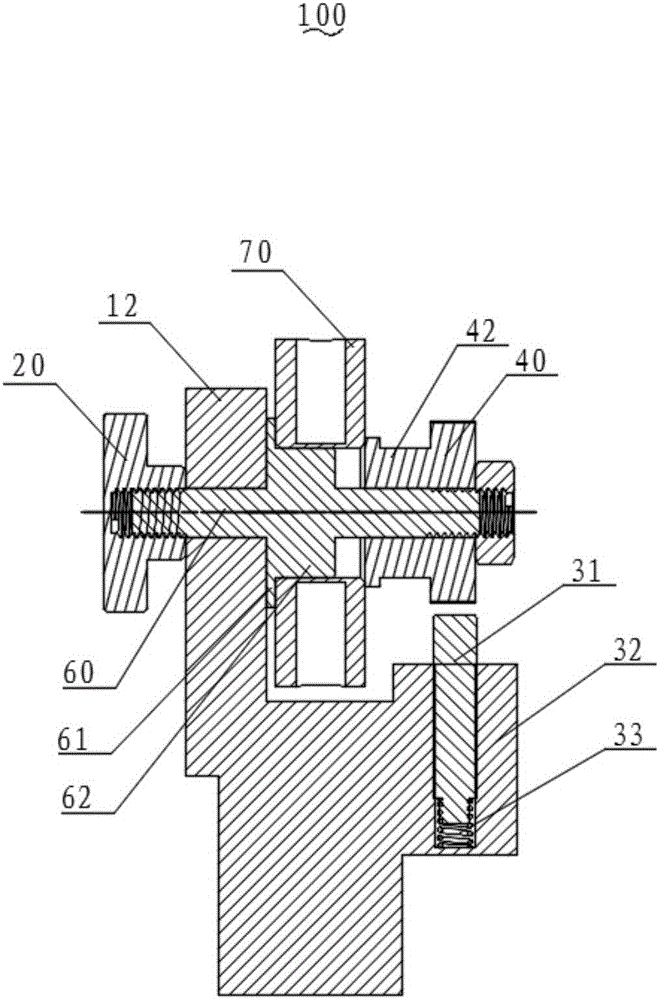

[0029] Please refer to Figure 1 to Figure 4 , a workpiece fixture with adjustable clamping angle, used for clamping workpieces, including a base 10, a connecting shaft 60, a handle 20, a ratchet 40, a non-return tappet 30 and a fixing member 50. One end of the connecting shaft 60 passes through the base 10 and is connected with the handle 20 , and the handle 20 fixes the connecting shaft 60 on the base 10 . The ratchet 40 is arranged on the connecting shaft 60, the workpiece is clamped between the connecting shaft 60 and the ratchet 40, and the fixing member 50 is connected to the other end of the connecting shaft 60 for fixing the ratchet 40 and the workpiece in the connection. on axis 60. A plurality of teeth are provided on the outer edge of the ratchet 40 , the non-return tappet 30 is arranged on the base 10 , and the non-retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com