Hot air evacuation type anti-freezing water feeding system of passenger train

A hot air and passenger technology, applied in the field of passenger train water supply system, can solve problems such as ballast bed deformation, endangering driving safety, blockage, etc., achieve timely and reliable water supply, prevent freezing blockage, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

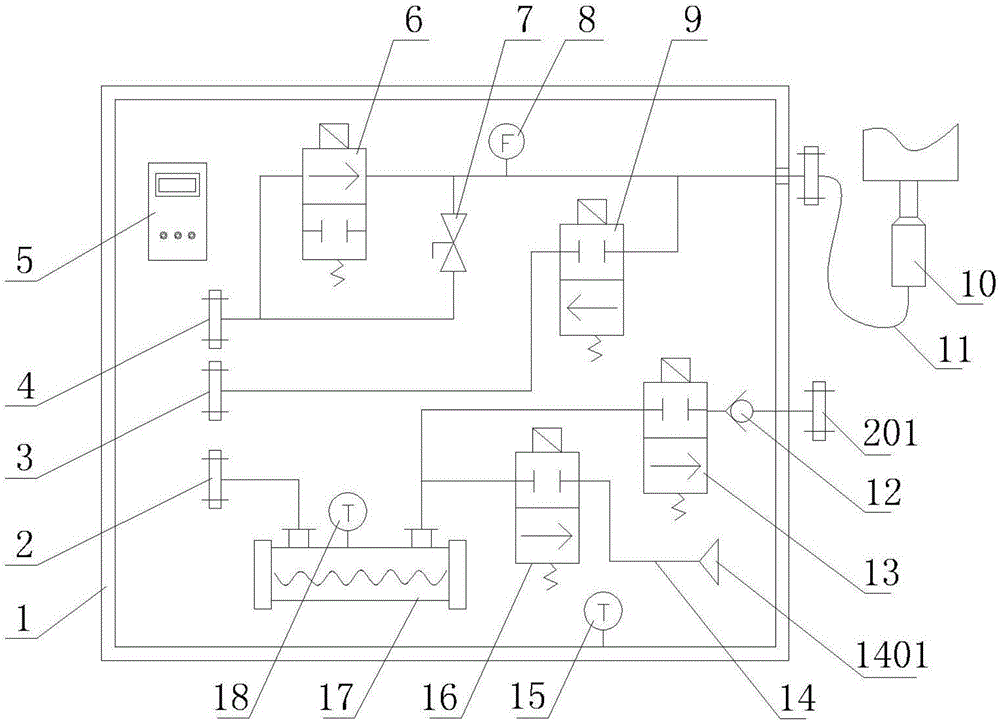

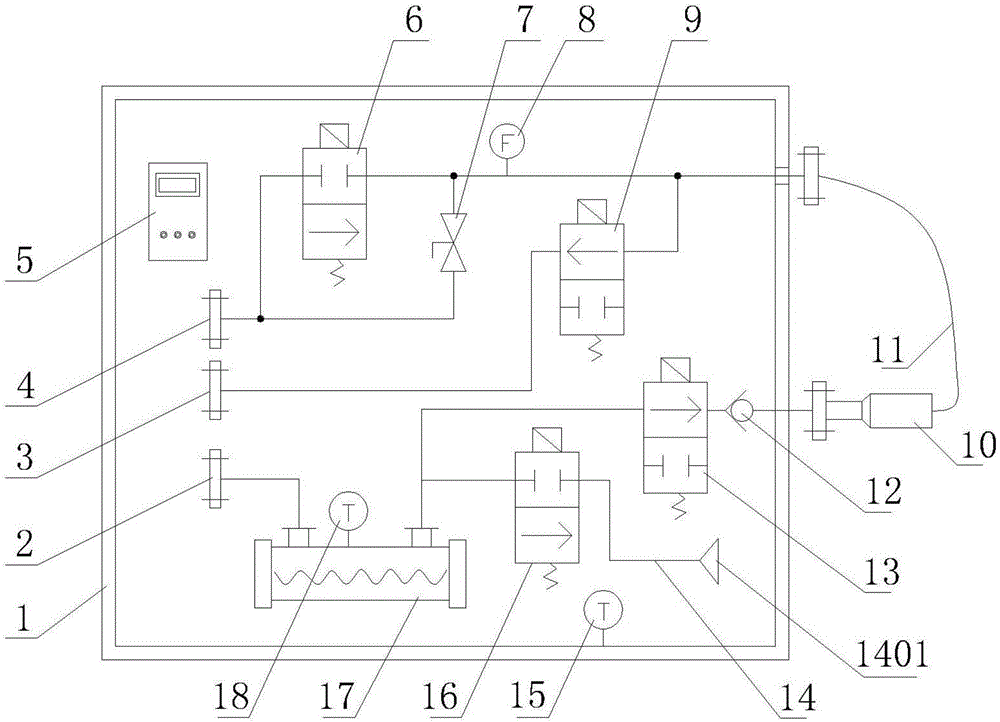

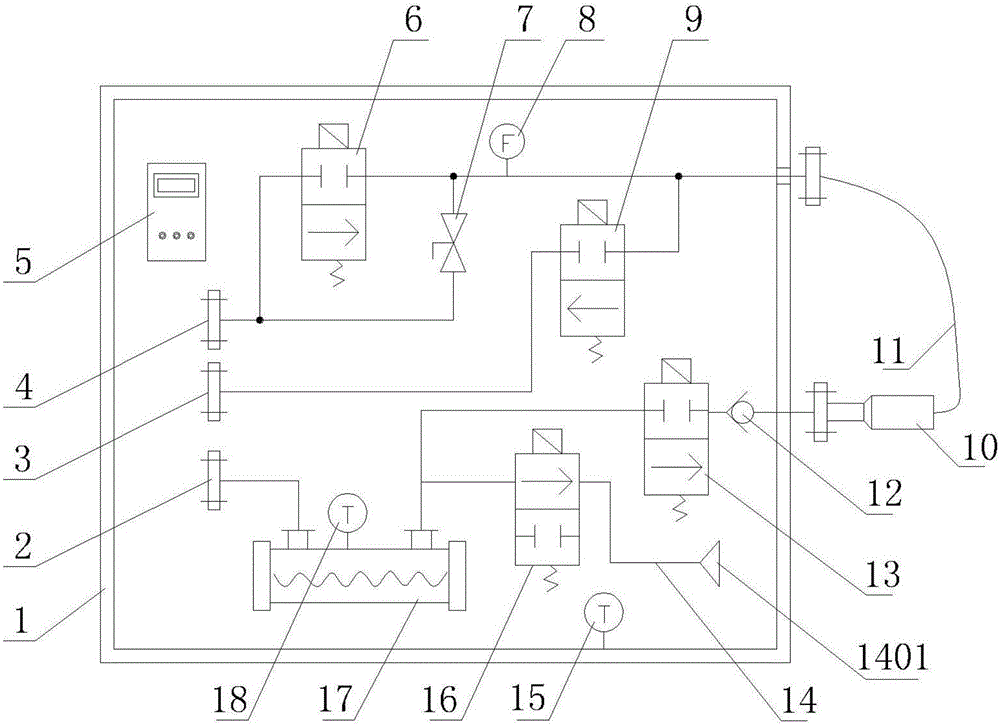

[0025] Such as figure 1 As shown, a kind of anti-freezing water filling system for hot air emptying passenger trains involved in the present invention includes several unit water supply stations 26, each unit water supply station 26 includes a thermal insulation room 1, and a water supply pipeline is arranged in the thermal insulation room 1 4. The drainage pipeline 3 and the hot air pipeline 2, the entrance of the water supply pipeline 4 is connected to the water supply pipeline of the station, the outlet of the water supply pipeline 4 is drawn from the heat preservation room 1 and connected to the water supply hose 11 and the water supply joint 10; the drainage pipeline The inlet 3 is connected with the middle part of the water supply pipeline 4, and the outlet of the drainage pipeline 3 is connected with the water circulation system of the station. A water supply solenoid valve 6 and a drain solenoid valve 9 are respectively installed on the water supply pipeline 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com