Production method for semi-processed electrical steel

A technology of semi-process electrical steel and production method, which is applied in the production field of semi-process cold-rolled non-oriented electrical steel, can solve problems such as unfavorable product deep processing, reduce product lamination coefficient, etc. Glitch increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1. Continuous casting is used to cast molten steel into billets and hot-roll to 2.15mm;

[0013] 2. Cold rolled to 0.54mm after pickling;

[0014] 3. Continuous furnace annealing is adopted after cold rolling, and N 2 +H 2 Atmosphere protection, N 2 : 65%; the rest is H 2 ;The temperature of the soaking section of the annealing furnace is 750°C, and the temperature is kept for 55s. The matrix structure has just undergone recrystallization, and the nucleation is uniform;

[0015] 4. Leveling, the reduction rate is 8%, the roughness Ra of the leveling roll on the leveling machine is: 2.0μm, the tension is controlled at 3KN, and the product thickness is 0.495mm;

[0016] 5. The coating is made into a finished product;

[0017] 6. Box furnace annealing, simulating user stress relief annealing, temperature 750°C, heat preservation 2h.

Embodiment 2

[0019] 1. Continuous casting is used to cast molten steel into billets and hot-roll to 2.2mm;

[0020] 2. Cold rolled to 0.55mm after pickling;

[0021] 3. Continuous furnace annealing is adopted after cold rolling, and N 2 +H 2 Atmosphere protection, N 2 : 70%; the rest is H 2 ;The temperature of the soaking section of the annealing furnace is 780°C, and the temperature is kept for 60s. The matrix structure has just undergone recrystallization, and the nucleation is uniform;

[0022] 4. Leveling, the reduction rate is 9%, the roughness Ra of the leveling roll on the leveling machine is: 2.5μm, the tension is controlled at 3KN, and the product thickness is 0.5mm;

[0023] 5. The coating is made into a finished product;

[0024] 6. Box furnace annealing, simulating user stress relief annealing, temperature 750°C, heat preservation 2h.

Embodiment 3

[0026] 1. Continuous casting is used to cast molten steel into billets and hot roll to 2.25mm;

[0027] 2. Cold rolled to 0.57mm after pickling;

[0028] 3. Continuous furnace annealing is adopted after cold rolling, and N 2 +H 2 Atmosphere protection, N 2 : 75%; the rest is H 2 ;The temperature of the soaking section of the annealing furnace is 790°C, and the temperature is kept for 65s. The matrix structure has just undergone recrystallization, and the nucleation is uniform;

[0029] 4. Leveling, the reduction rate is 13%, the roughness Ra of the leveling roll on the leveling machine is: 3.0μm, the tension is controlled at 4KN, and the product thickness is 0.493mm;

[0030] 5. The coating is made into a finished product;

[0031] 6. Box furnace annealing, simulating user stress relief annealing, temperature 750°C, heat preservation 2h.

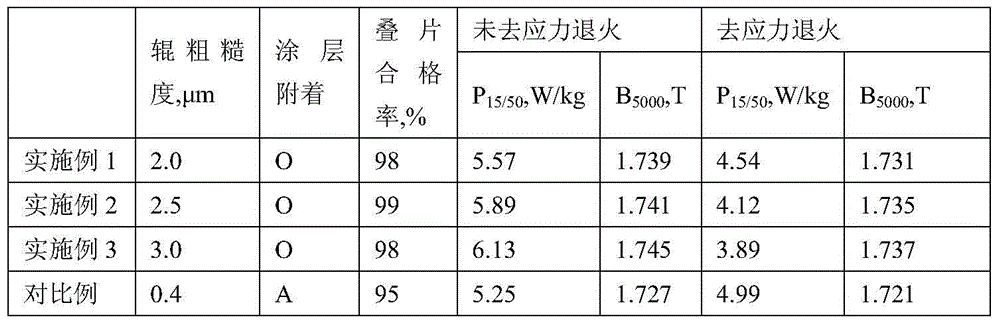

[0032] The performance of the product obtained according to the above process is as follows:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com