Fine-tuning cradle structure

A technology of cradle and adjusting bracket, which is applied in textiles and papermaking, drafting equipment, spinning machines, etc. It can solve the problems of pressure and angle changes of cradle, influence on yarn consistency, low assembly efficiency, etc., and achieve stable cradle Reduce the pressure value of the rack, reduce labor intensity, and solve the effect of automatic pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

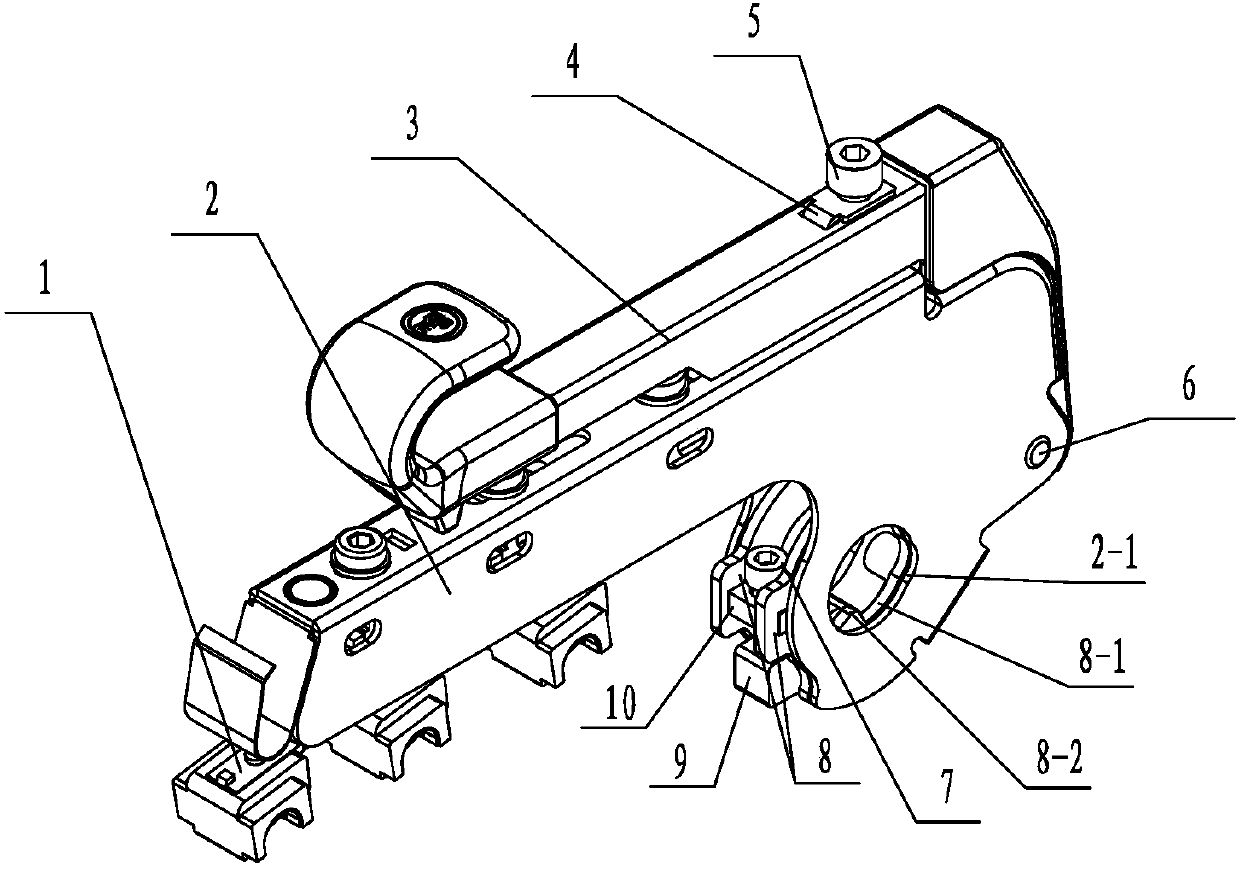

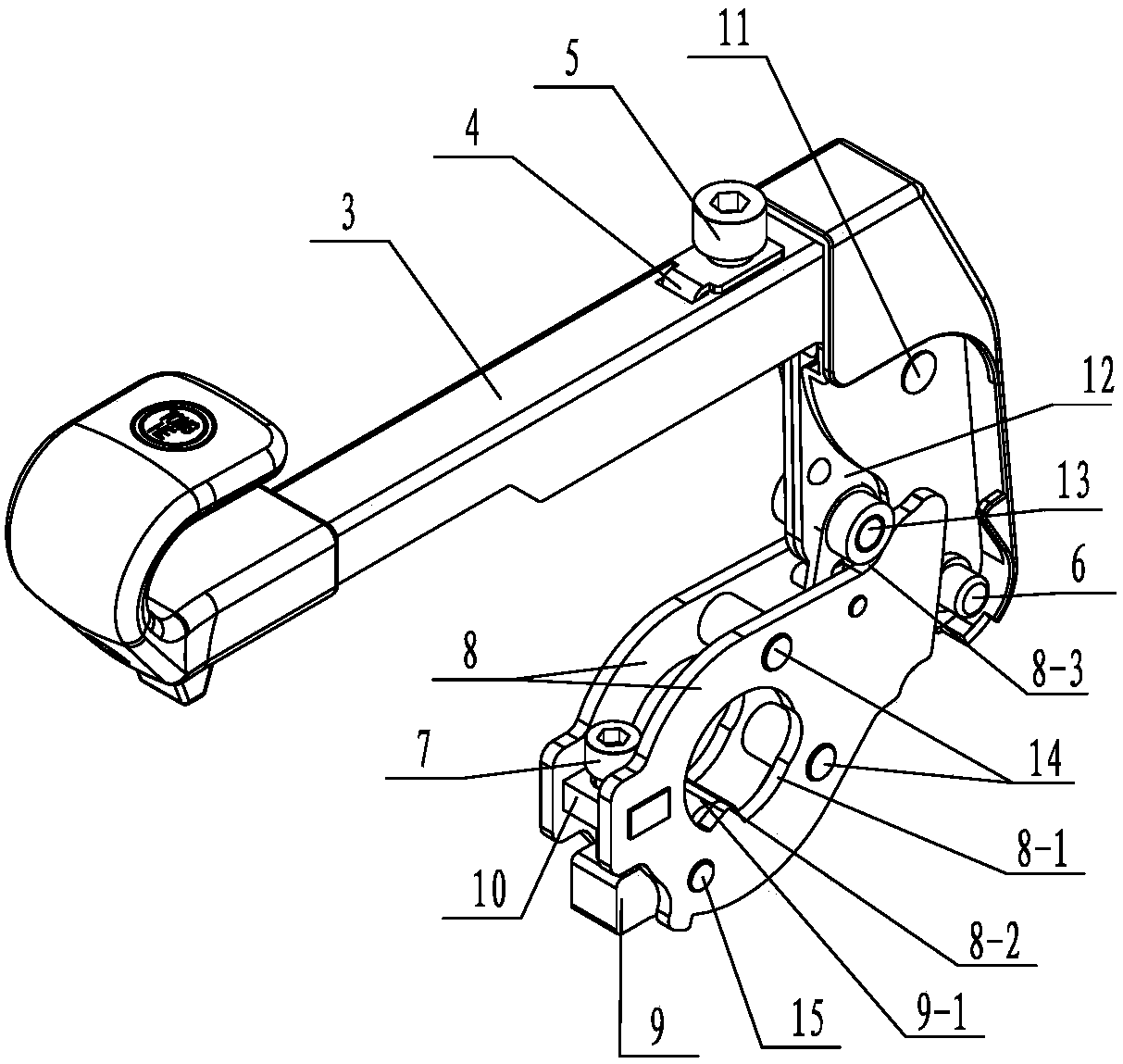

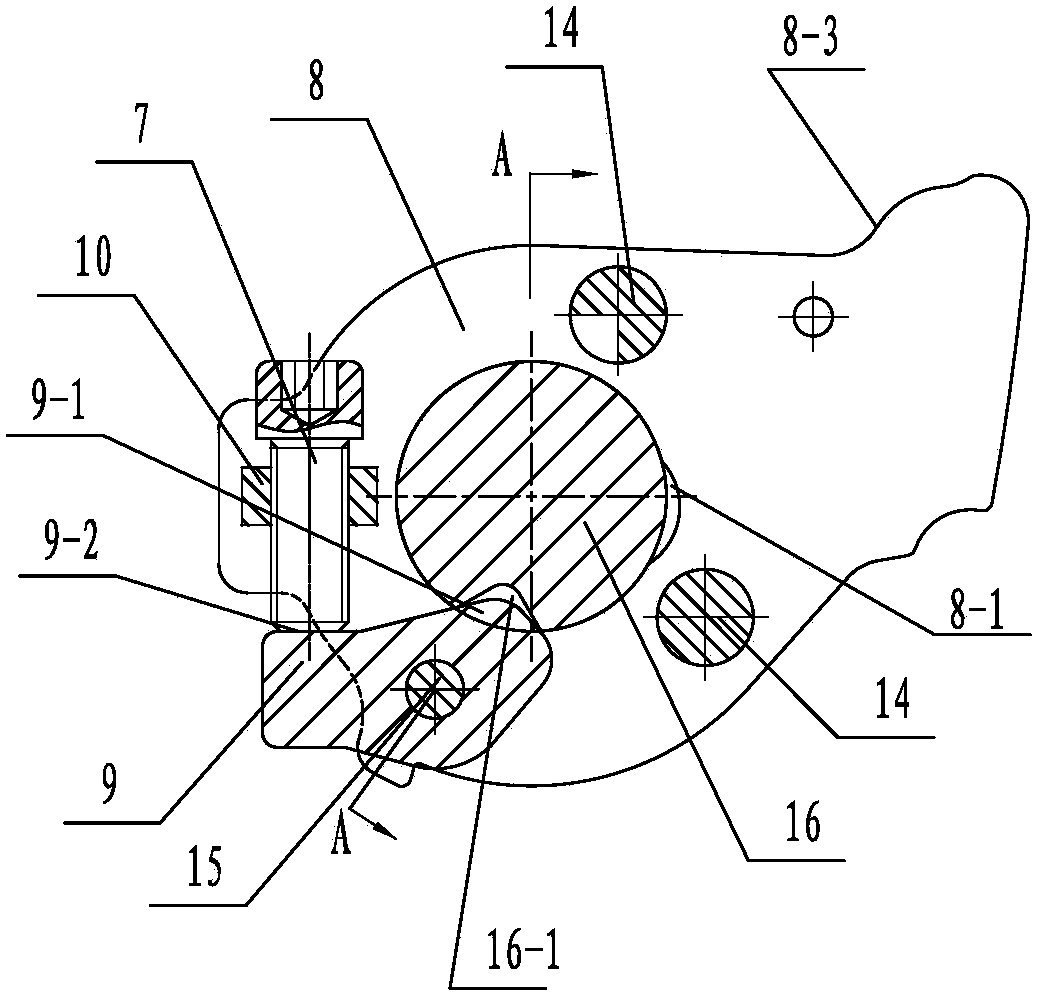

[0023] See Figure 1~5 As shown, the fine-tuning cradle structure of the present invention includes a handle 3, a cradle body 2 hinged on the handle 3, at least three pressurizing mechanisms 1 arranged on the cradle body 2, and a rod shaft for The upper locking mechanism on 16, the cradle body 2 and the two locking plates 8 of the locking mechanism are provided with the first pole hole 2-1 and the second pole hole 8-1 through which the pole shaft 16 passes, The first pole hole 2-1 of the cradle body 2 and the second pole hole 8-1 on the two locking pieces 8 are connected to the pole shaft 16 through the pole shaft 16, and the pole shaft 16 is then Installed on the machine base, each pressing mechanism 1 of the present invention adopts the existing structure, and the holding seat on each pressing mechanism 1 is then connected to the corresponding top roller, so that the top roller and each bottom roller correspond to form a drafting zone, and the fiber Do the drafting.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com