Concave rib weathering resistant steel-concrete combination bridge deck

A technology for concrete slabs and composite bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of high welding process requirements and large amount of steel coating, so as to ensure industrialized construction, save steel consumption, and reduce the weight of the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

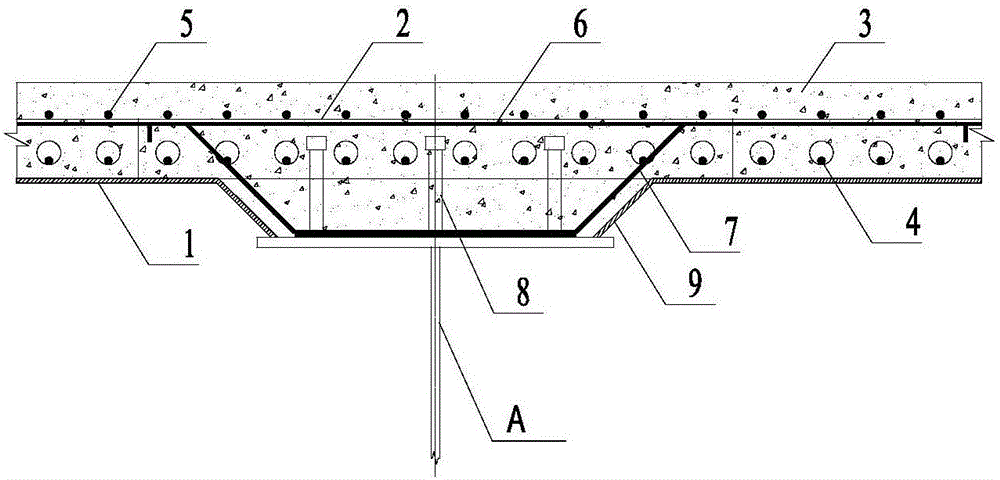

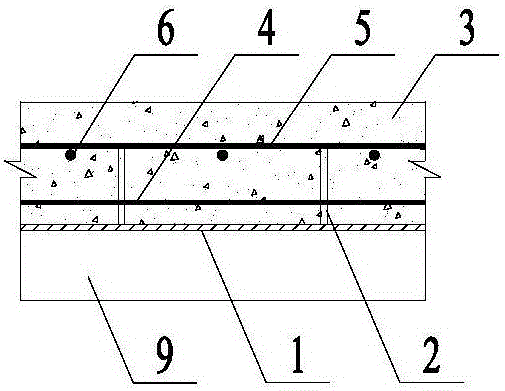

[0020] figure 1 , figure 2 The components and corresponding targets shown in the above are the existing steel-concrete composite bridge deck structure, specifically including the bottom steel plate 1 and the cast-in-place concrete slab 3 poured on it, and connecting the bottom steel plate 1 and the cast-in-place concrete slab 3 into one shear key. The shear key includes a steel plate with holes 2 welded on the bottom steel plate 1, and a steel bar shear key welded and fixed on the surface of the bottom steel plate 1. The cast-in-place concrete slab 3 is formed by pouring concrete on the slab surface of the bottom steel plate 1, and a steel bar shear key is embedded therein. The steel bar shear key includes a longitudinal steel bar 4 inside the hole of the steel plate with holes, a longitudinal steel bar 5 outside the hole, and a transverse steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com