Reducing reamer

A technology of a reamer and a body, which is applied in the special field of horizontal directional drilling method, can solve the problems of delaying human and material resources, wasting time, energy, material resources, financial resources, reverse reaming, etc. The effect of working efficiency, expanding the scope of application and reducing the risk of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

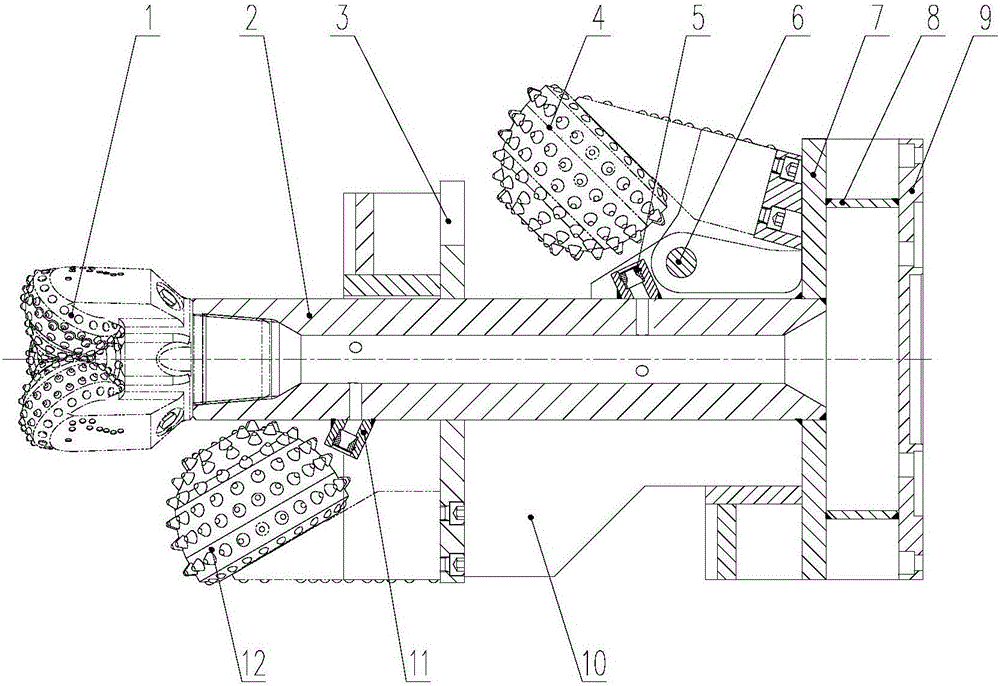

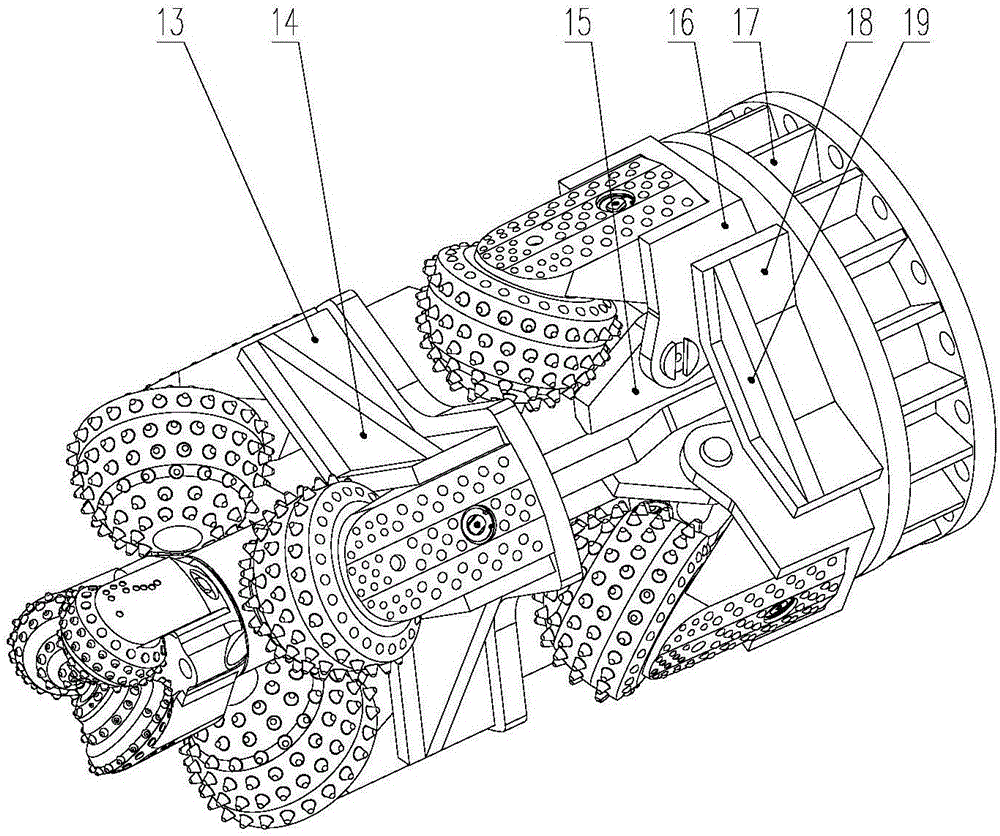

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0025] A variable diameter reamer, such as figure 1 and figure 2 As shown, the reamer body 2, the tri-cone bit 1, the fixed cone 12, the reversing cone 4 and the connection plate 9 are included. The front end of the reamer body 2 is the advancing direction of reaming, and the rear end is connected to the drilling rig, the pipe jacking machine or the power mechanism of the reamer through the connection plate 9 . The reamer body 2 is respectively connected with the three-cone bit 1, the fixed cone 12, the reversing cone 4 and the connecting plate 9 from front to back.

[0026] The head of the three-cone bit 1 is a structure in which three cones are fixedly connected, and the tail is a threaded rod with a tapered thread. The front end of the reamer body 2 is correspondingly provided with an internal thread taper hole. The reamer body 2 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com