Large-aperture aspheric surface measurement system and method based on real-time computer-generated hologram

A technology of real-time calculation and measurement methods, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of large return error in non-zero position measurement, low spatial resolution, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

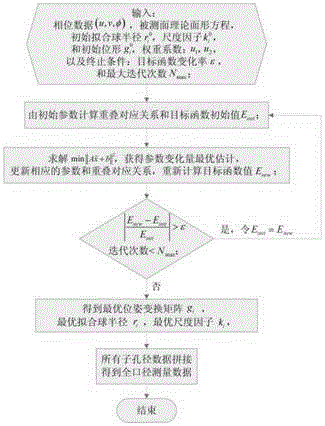

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in further detail below in conjunction with accompanying drawing:

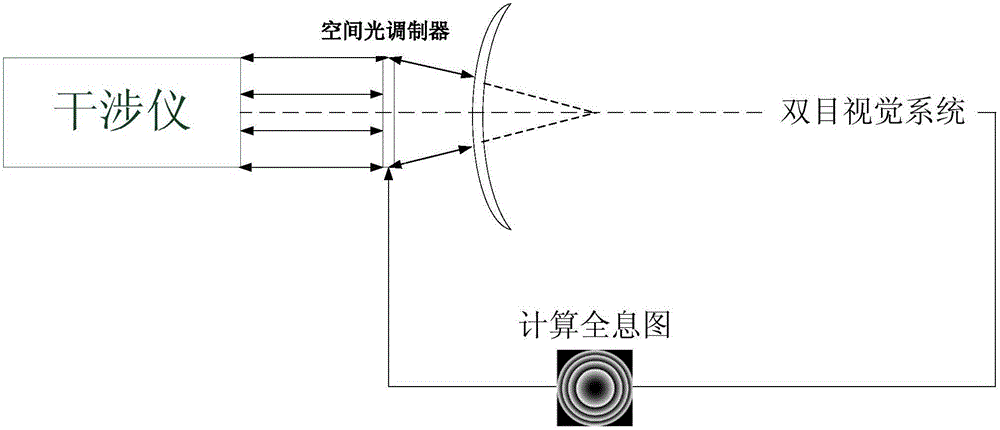

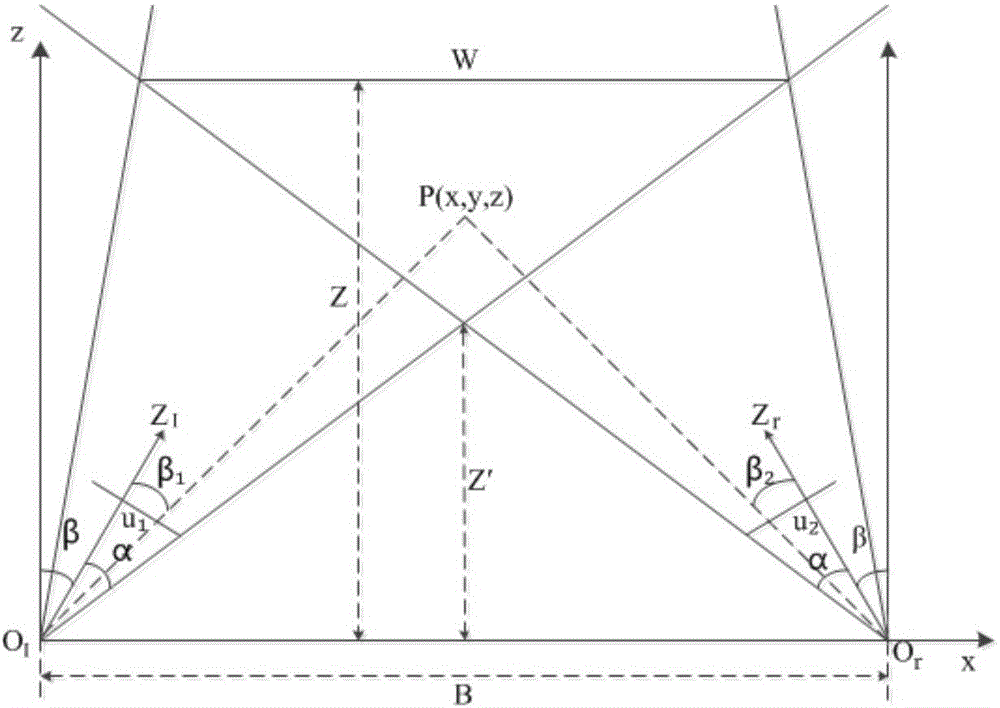

[0054] refer to figure 1 , a schematic diagram of a measurement system based on real-time CGH involved in the present invention, the system is mainly composed of a spatial light modulator 1, an interferometer 3, a stereo binocular vision system 5, a calibration ball target 7, and an image acquisition card 9. The tested aspheric mirror is arranged between the spatial light modulator 1 and the stereo binocular vision system 5 .

[0055]The spatial light modulator 1 is a type of optoelectronic device that modulates the wavefront and is used for real-time CGH compensation. In this embodiment, a transmissive phase liquid crystal spatial light modulator is used to display CGH in real time, so that the phase of the incident plane wavefront can be dynamically modulated to obtain the required aspheric wavefront. Distributed control has great advantages.

[0056] The interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com