Method and system for quickly detecting damage to composite material plate

A composite material plate and detection method technology, applied in the direction of analyzing materials, testing of machine/structural components, measuring devices, etc., can solve internal damage of materials, complex mechanical properties and behaviors of composite materials, threats to overall structural safety and normal service, etc. problem, to achieve the effect of good operation performance and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In one embodiment, a rapid damage detection method for a composite material board is provided. The method includes the following steps:

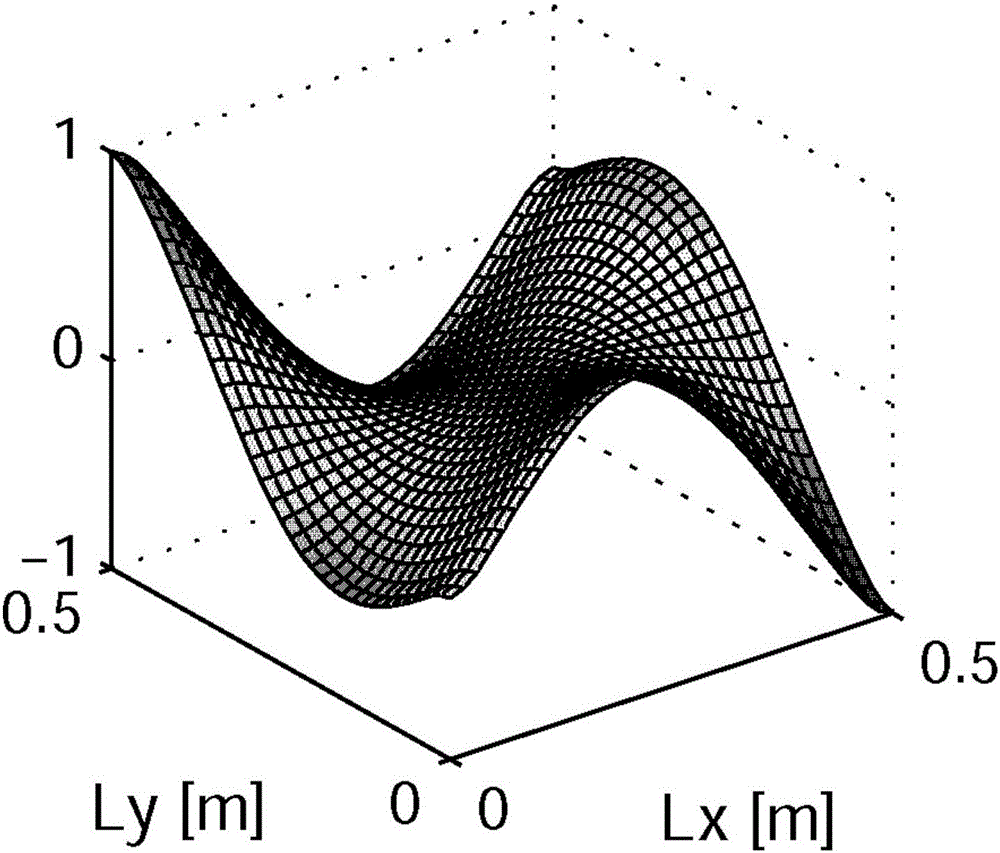

[0032] S100. Perform a modal test on the composite material plate to obtain the modal shape data, and then obtain the modal shape surface;

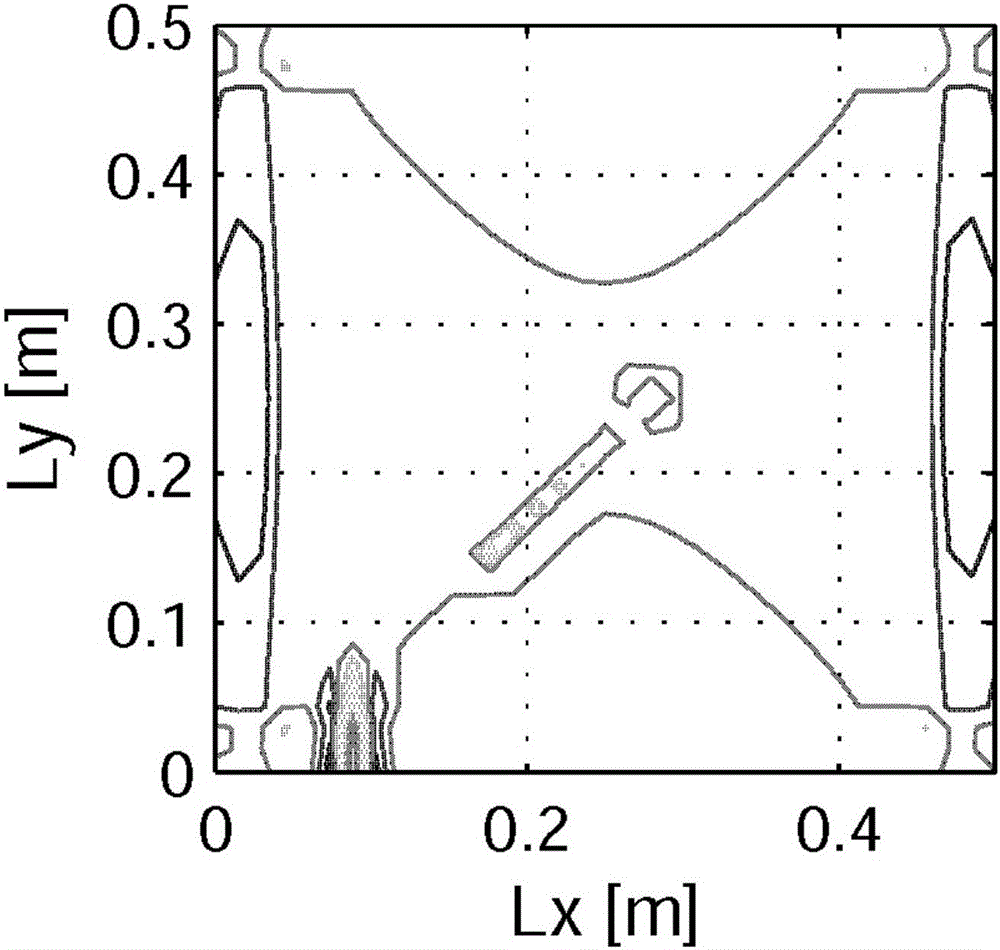

[0033] S200. Calculate the two-dimensional generalized local entropy of the modal data points on the modal surface;

[0034] S300: Determine whether there are abnormal data in the two-dimensional generalized local entropy;

[0035] S400. If there is abnormal data in S300, it is judged that the composite material board is damaged; otherwise, it is judged that the composite material board is healthy;

[0036] The two-dimensional generalized local entropy is expressed as follows:

[0037] H ( p ( x i , y j ) ) = - p ( x i , y j ) log 2 p ( x i , y j ) log 2 ( N + 1 )

[0038] Where:

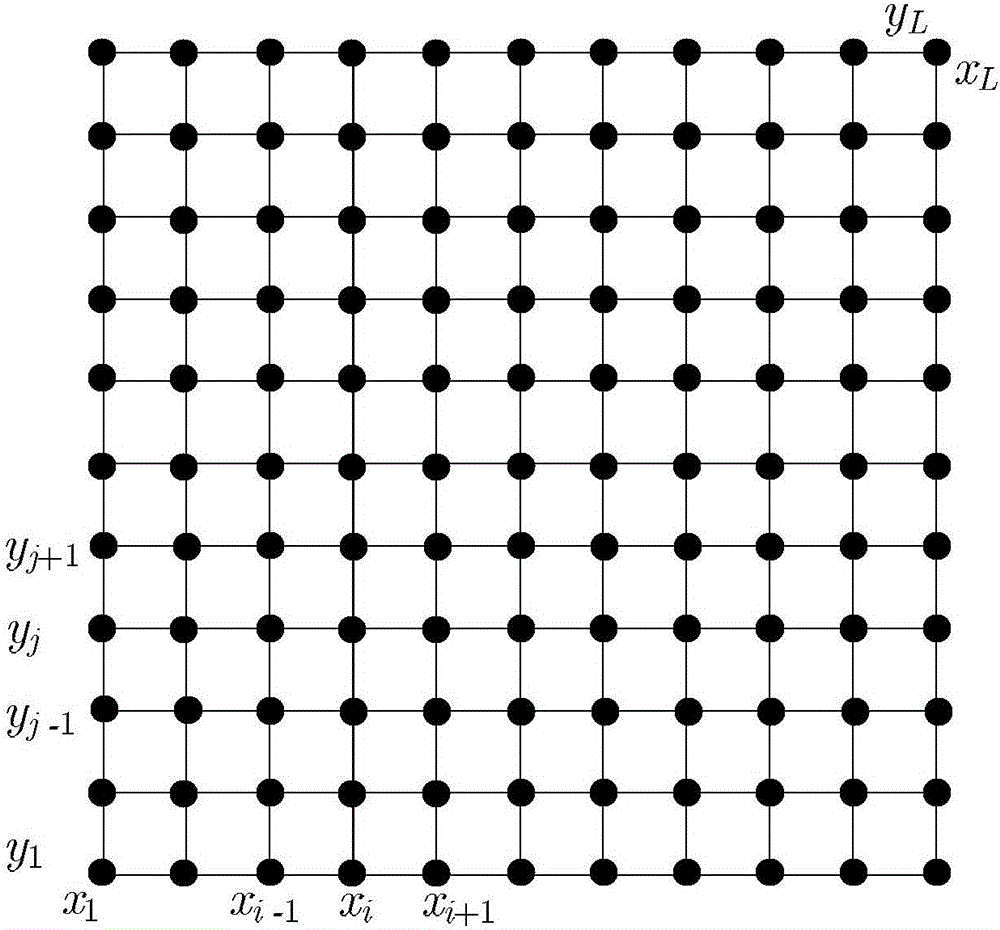

[0039] p(x i ,y j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com