Double-sided light emitting device for OLED display screen and preparation method

A double-sided light-emitting, display screen technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve problems such as complex processes, and achieve the effects of simple process, improved color rendering index, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

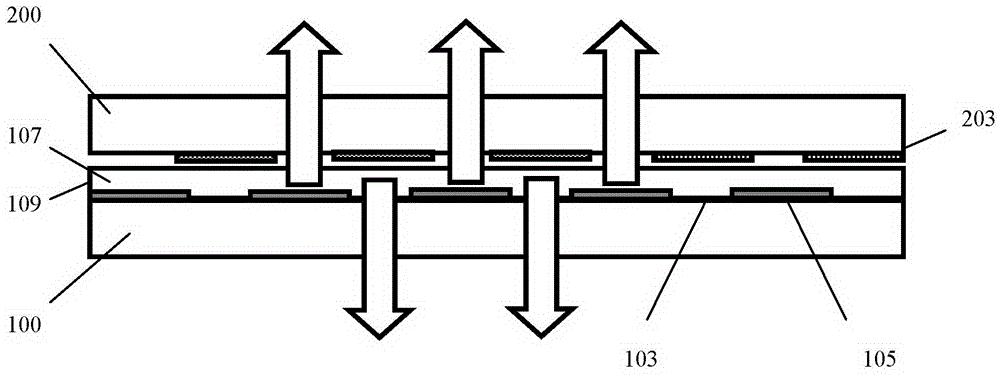

[0032] Please refer to figure 1 , the OLED display double-sided light-emitting device of the present invention includes a substrate 100, an anode layer, an organic light-emitting layer 109, a cathode layer 107, and an encapsulation cover 200 stacked in sequence, wherein the anode layer includes transparent Anode layer 103 and non-transparent anode layer 105 ; opaque positions and transparent positions arranged in a matrix form and complementary to the transparent anode layer 103 and non-transparent anode layer 105 are arranged inside the package cover 200 .

[0033] Preferably, the anode material is a material with high work function and light transmittance. As a specific example, the anode is a transparent conductive film of ITO with a high work function of 4.5eV-5.3eV, stable properties and light transmission.

[0034] Preferably, the opaque positions of the package cover 200 and the light-emitting areas on the substrate 100 using opaque metal as anodes are arranged in a sta...

no. 2 example

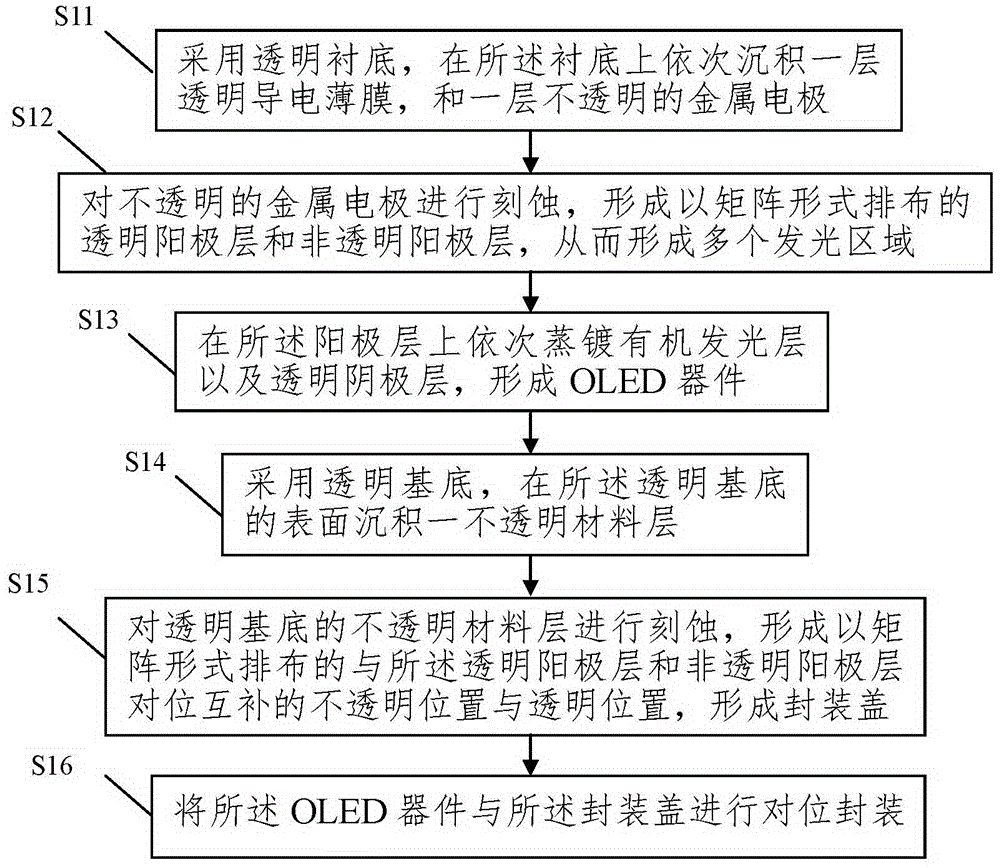

[0041] This embodiment is to provide a method for preparing an OLED display device that emits light on both sides, including: S11, using a transparent substrate, and sequentially depositing a layer of transparent conductive film and a layer of opaque metal electrodes on the substrate; S12, etching the opaque metal electrode to form a transparent anode layer and a non-transparent anode layer arranged in a matrix, thereby forming multiple light-emitting regions; S13, sequentially vapor-depositing an organic light-emitting layer and a transparent anode layer on the anode layer A cathode layer, forming an OLED device; S14, using a transparent substrate, depositing an opaque material layer on the surface of the transparent substrate; S15, etching the opaque material layer of the transparent substrate to form a matrix arranged in a matrix with the transparent The anode layer and the non-transparent anode layer align complementary opaque positions and transparent positions to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com