Positive electrode of lithium ion battery

A lithium-ion battery and positive electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of low battery performance, low electrode conductivity, discharge specific capacity attenuation, etc., and reduce high-speed stirring. time, overcome the low conductivity, and enhance the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

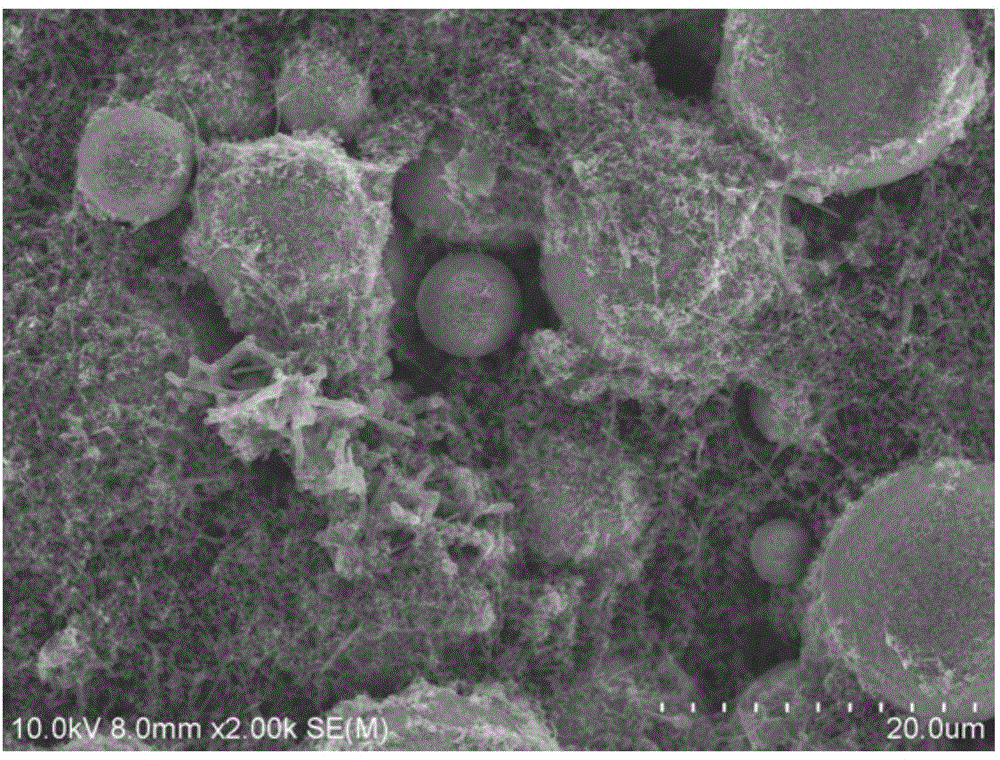

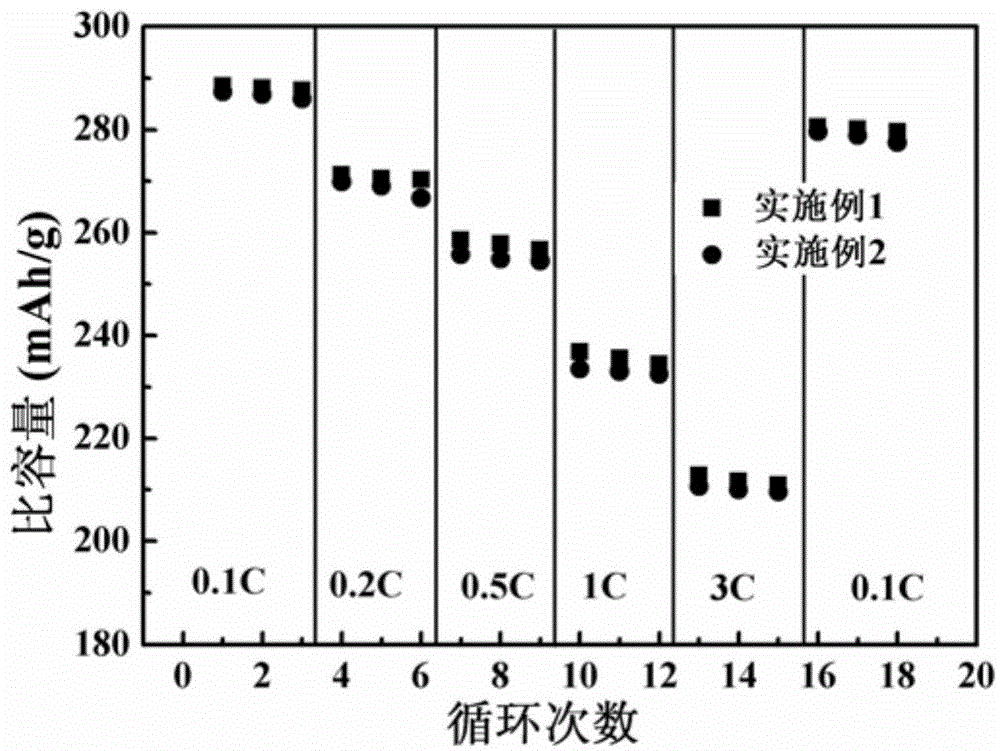

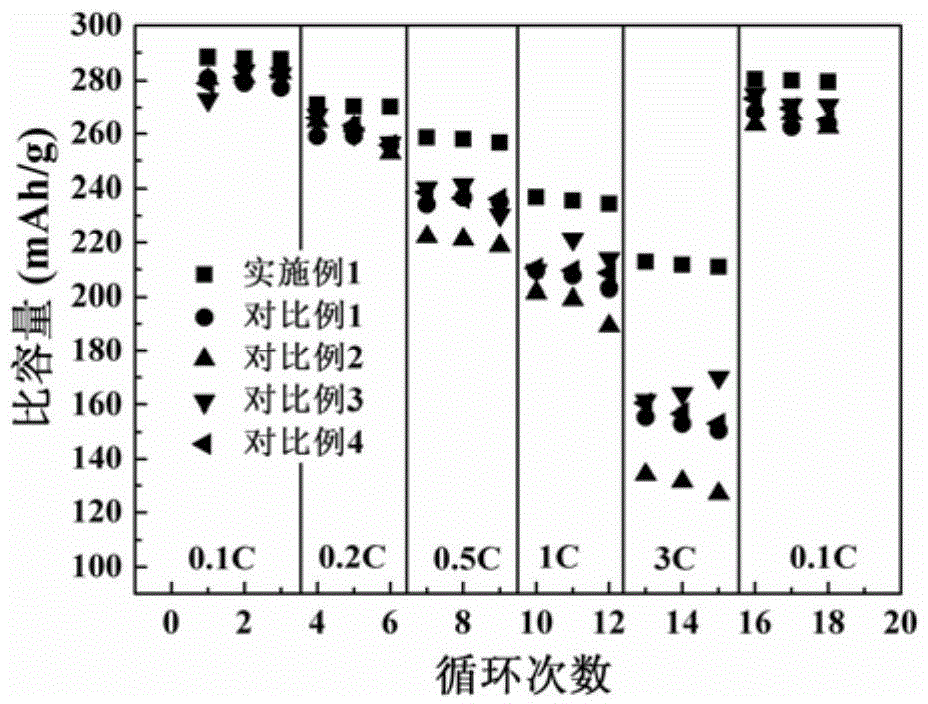

[0021] The active material of the positive electrode is 0.6Li 2 O 0.8Mn 0.675 Ni 0.1625 co 0.1625 o 1.75 , the conductive agent selects nanoscale conductive carbon black (SuperP), carbon nanotubes, and graphene. Calculated according to weight percentage, SuperP accounts for 33.33% by weight of the conductive agent, and graphene accounts for 33.33% by weight of the conductive agent. The weight percentage of the nanotubes in the conductive agent is 33.33%. The binder is polyvinylidene fluoride (PVDF), and the solvent is N-methylpyrrolidone. The weight percentage of active material: conductive agent: binder is 80:10:10. Dissolve 0.500g of PVDF in 9.500g of N-methylpyrrolidone to form a PVDF solution; then weigh 0.167g of SuperP, 0.167g of graphene, and 0.167g of carbon nanotubes, and add the weighed conductive agent to about 2.000g of N-methylpyrrolidone, ultrasonically disperse for 0.3h; then add binder solution and 4.000g of active material, and stir at high speed for 0.5...

Embodiment 2

[0023] The active material of the positive electrode is 0.6Li 2 O 0.8Mn 0.675 Ni 0.1625 co 0.1625 o 1.75 The conductive agent is selected from nano-scale conductive carbon black SuperP, graphene, and carbon nanofibers. According to the weight percentage, SuperP accounts for 33.33% by weight of the conductive agent, and graphene accounts for 33.33% by weight of the conductive agent. Carbon nanofibers It accounts for 33.33% by weight of the conductive agent. The binder is polyvinylidene fluoride (PVDF), and the solvent is N-methylpyrrolidone. The weight percentage of active material: conductive agent: binder is 80:10:10. Dissolve 0.500g of PVDF in 9.500g of N-methylpyrrolidone to form a PVDF solution; then weigh 0.167g of SuperP, 0.167g of graphene, and 0.167g of carbon nanofibers, and add the weighed conductive agent to about 2.200g of N-methylpyrrolidone, ultrasonically disperse for 0.5h; then add binder solution and 4.000g of active material, and stir at high speed for ...

Embodiment 3

[0025] The active material of the positive electrode is 0.6Li 2 O 0.8Mn 0.675 Ni 0.1625 co 0.1625 o 1.75 The conductive agent is selected from nano-scale conductive carbon black SuperP, graphene, and carbon nanofibers. Calculated by weight percentage, SuperP accounts for 70% by weight of the conductive agent, and graphene accounts for 10% by weight of the conductive agent. Carbon nanofibers Accounting for 20% by weight of the conductive agent. The binder is polyvinylidene fluoride (PVDF), and the solvent is N-methylpyrrolidone. The weight percentage of active material: conductive agent: binder is 80:10:10. Dissolve 0.500g of PVDF in 9.500g of N-methylpyrrolidone to form a PVDF solution; then weigh 0.350g of SuperP, 0.050g of graphene, and 0.100g of carbon nanofibers, and add the weighed conductive agent to about 2.200g of N-methylpyrrolidone, ultrasonically disperse for 0.5h; then add binder solution and 4.000g of active material, and stir at high speed for 0.2h to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com