Preparation method of delicious and easily cooked black rice

A technology of cooking black and delicious food, which is applied in the field of grain processing, can solve the problems of shortening cooking time, difficulty in cooking black rice, and soft taste of black rice, and achieve the effect of shortening cooking time, reducing product quality and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing delicious and easy-to-cook black rice, the method comprising the following process steps:

[0024] (1) At first 60kg of black rice raw material (water content 25wt%) is transported into the fluidization chamber, the fluidization temperature is 135°C, the fluidization treatment time is 60s, and the feed rate is 45kg / h;

[0025] (2) then the black rice of fluidization treatment is placed on the cool bed of wire mesh and naturally stacked and slowed down for 40min;

[0026] (3) Carry out microwave-far-infrared enzymatic inactivation treatment for 3 minutes under the condition of 80-110° C. to the black rice cooled to room temperature;

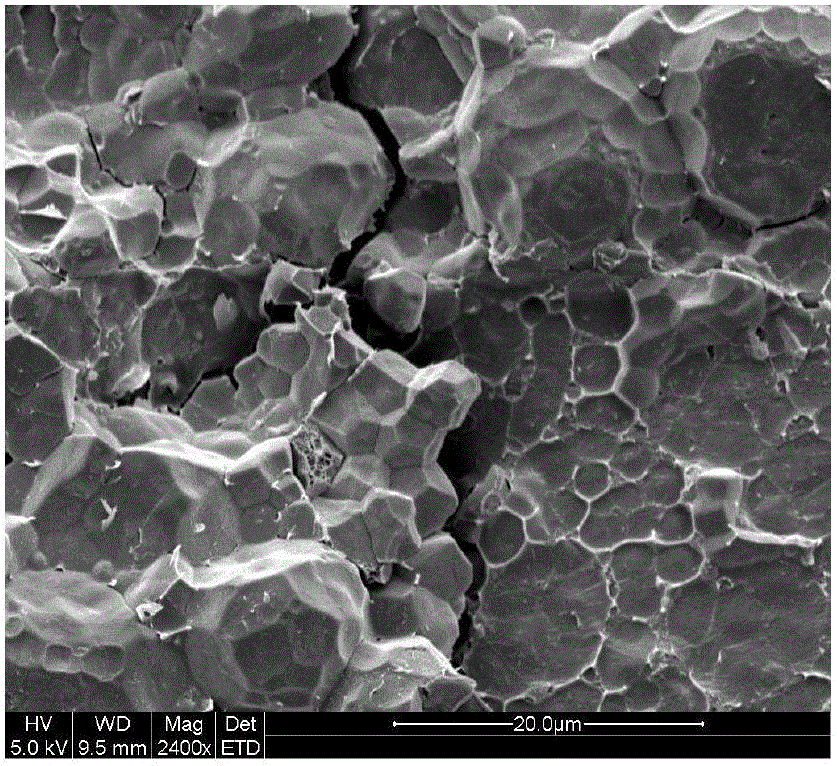

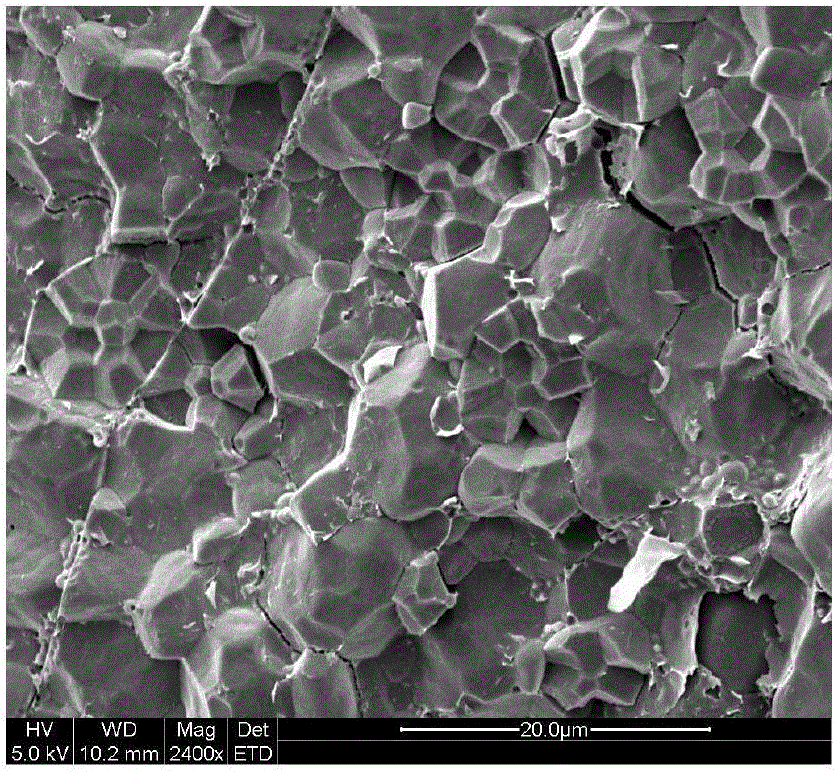

[0027] (4) Finally, the black rice processed in step (3) is bagged, degassed and hermetically sealed to obtain the finished product. The product water absorption rate, optimal cooking time, and antioxidant activity test results are shown in Table 1; the scanning electron microscope of the cross-sectional structure of...

Embodiment 2

[0030] A method for preparing delicious and easy-to-cook black rice, the method comprising the following process steps:

[0031] (1) At first 100kg of black rice raw material (water content 20wt%) is transported into the fluidization chamber, the fluidization temperature is 155°C, the fluidization treatment time is 40s, and the feed rate is 70kg / h;

[0032] (2) then the black rice of fluidization treatment is placed on the cool bed of wire mesh and naturally stacked and slowed down for 30min;

[0033] (3) To the black rice cooled to room temperature, carry out microwave-far-infrared enzymatic treatment for 3 minutes under the condition of 95 DEG C;

[0034] (4) Finally, the black rice processed in step (3) is bagged, degassed and hermetically sealed to obtain the finished product. The test results of product water absorption, optimal cooking time and antioxidant activity are shown in Table 1.

Embodiment 3

[0036] A method for preparing delicious and easy-to-cook black rice, the method comprising the following process steps:

[0037] (1) At first 120kg of black rice raw material (water content 15wt%) is transported into the fluidization chamber, the fluidization temperature is 180°C, the fluidization treatment time is 30s, and the feed rate is 120kg / h;

[0038] (2) then the black rice of fluidization treatment is placed on the cool bed of wire mesh and naturally stacked and slowed down for 20min;

[0039] (3) To the black rice cooled to room temperature, carry out microwave-far-infrared enzymatic treatment for 3 minutes under the condition of 80 DEG C;

[0040] (4) Finally, the black rice processed in step (3) is bagged, degassed and hermetically sealed to obtain the finished product.

[0041] The conditions for microwave-far infrared enzyme inactivation in the step (3) are: temperature 80° C., time 3 minutes. The test results of product water absorption, optimal cooking time a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com