Production method and system for continuously producing high-elasticity marinated eggs

A production method and a technology for marinating eggs, which are applied in the field of food processing to achieve the effects of low drying temperature, improved production efficiency and complete marinating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

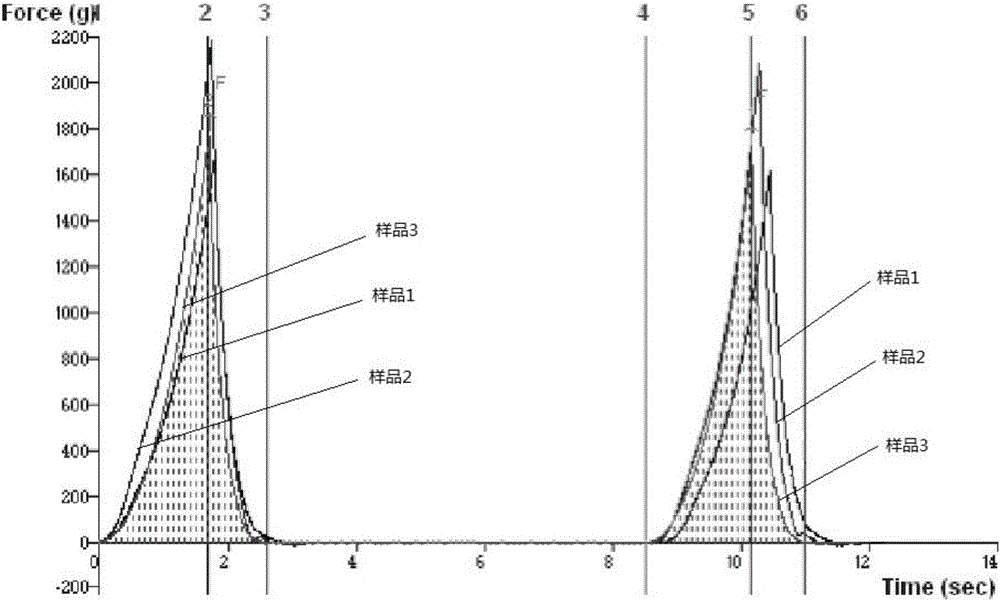

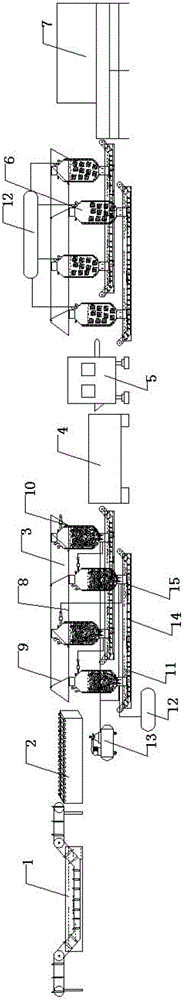

[0047] A method for preparing high-elastic marinated eggs, the specific steps are as follows:

[0048] (1) Cooking of eggs: the selected eggs are sent to 85°C with a mass percentage of 2% hot salt water in a water tank through a conveyor belt, and precooked for 15 minutes;

[0049] (2) Automatic shelling of eggs: use an automatic shelling machine to shell cooked eggs;

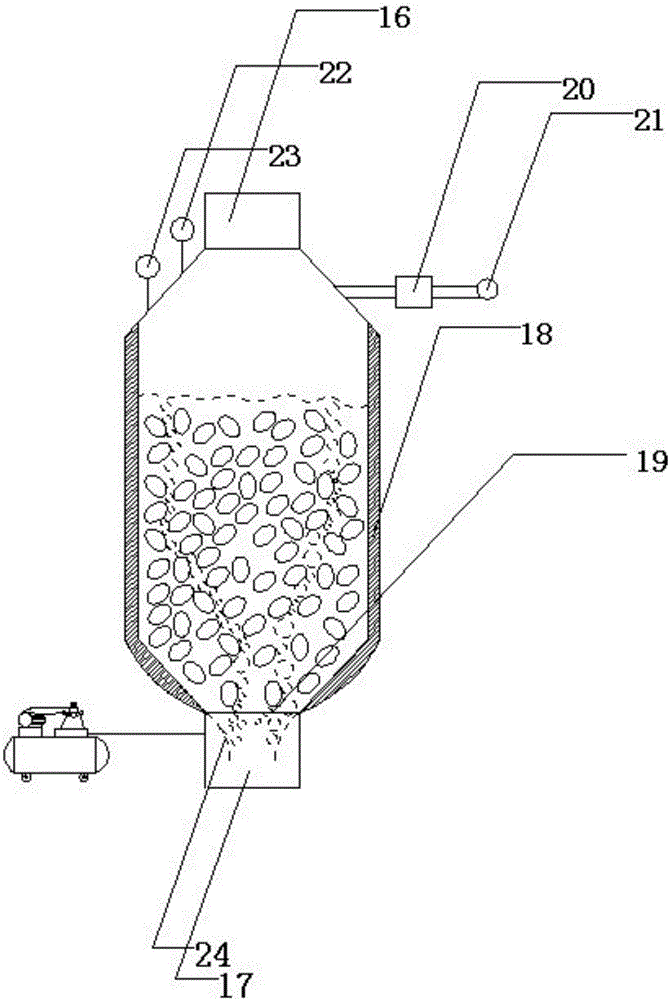

[0050] (3) Braining of shelled eggs: the shelled eggs are conveyed to a continuous high-pressure stewing device for high-pressure stewing by a conveyor belt. Under the condition of 105°C and 0.15 MPa, the eggs are stewed for 60 minutes in the presence of air;

[0051] (4) Reduced pressure (-0.01MPa) microwave drying of marinated eggs: place the matured marinated eggs in a reduced pressure (-0.01MPa) microwave drying tunnel to dry for 120s;

[0052] (5) Packaging of spiced eggs: the dried spiced eggs are placed in a packaging machine for packaging;

[0053] (6) Sterilization of packaged corned eggs: transfer t...

Embodiment 2

[0056] A kind of preparation method of highly elastic stewed duck egg, concrete steps are as follows:

[0057] (1) Cooking of duck's eggs: the selected duck's eggs are sent to 95° C. by mass percentage in a 1% hot salt water tank through a conveyor belt, and precooked for 9 minutes;

[0058] (2) Automatic shelling of duck eggs: shell the cooked duck eggs with an automatic shelling machine;

[0059] (3) Braining of shelled duck eggs: The duck eggs after shelling are conveyed to a continuous high-pressure stewing device for high-pressure stewing through a conveyor belt. Under the condition of 107°C and 0.2 MPa, stew for 50 minutes in the presence of nitrogen;

[0060] (4) Reduced pressure (-0.02MPa) microwave drying of marinated eggs: place the matured marinated eggs in a reduced pressure (-0.02MPa) microwave drying tunnel to dry for 150s;

[0061] (5) Packaging of spiced eggs: the dried spiced eggs are placed in a packaging machine for packaging;

[0062] (6) Sterilization of...

Embodiment 3

[0065] A kind of preparation method of highly elastic stewed goose egg, concrete steps are as follows:

[0066] (1) Cooking of goose eggs: the selected goose eggs are sent to a 0.5% hot salt water tank at 100°C through a conveyor belt, and precooked for 7 minutes;

[0067] (2) Automatic shelling of goose eggs: use an automatic shelling machine to shell the cooked goose eggs;

[0068] (3) Braining of shelled goose eggs: the goose eggs after shelling are conveyed to a continuous high-pressure stewing device for high-pressure stewing by a conveyor belt. Under the condition of 110°C and 0.25 MPa, stew for 40 minutes with a stirring system;

[0069] (4) Reduced pressure (-0.03MPa) microwave drying of marinated eggs: place the matured marinated eggs in a reduced pressure (-0.03MPa) microwave drying tunnel to dry for 200s;

[0070] (5) Packaging of spiced eggs: the dried spiced eggs are placed in a packaging machine for packaging;

[0071] (6) Sterilization of packaged corned eggs:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com