A plastic bottle automatic forming liquid filling machine

An automatic molding, plastic bottle technology, used in bottling machines, bottle filling, liquid handling, etc., can solve the problems of plastic bottles being difficult to stand, the molding yield is not very high, and the leftovers are increased. Integrated and automated processes, reduced deformation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

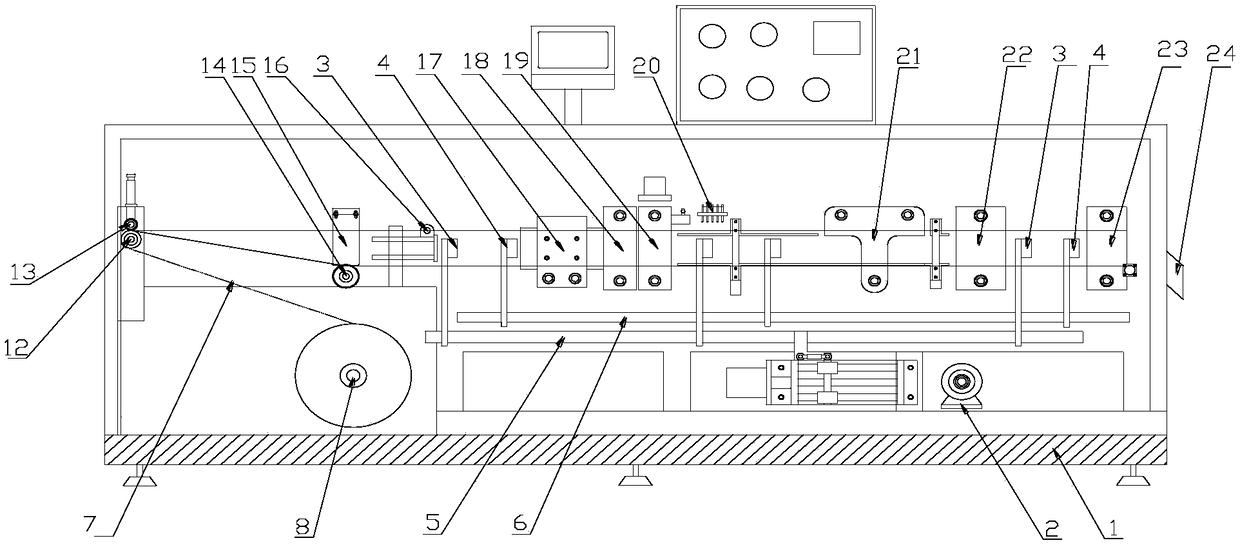

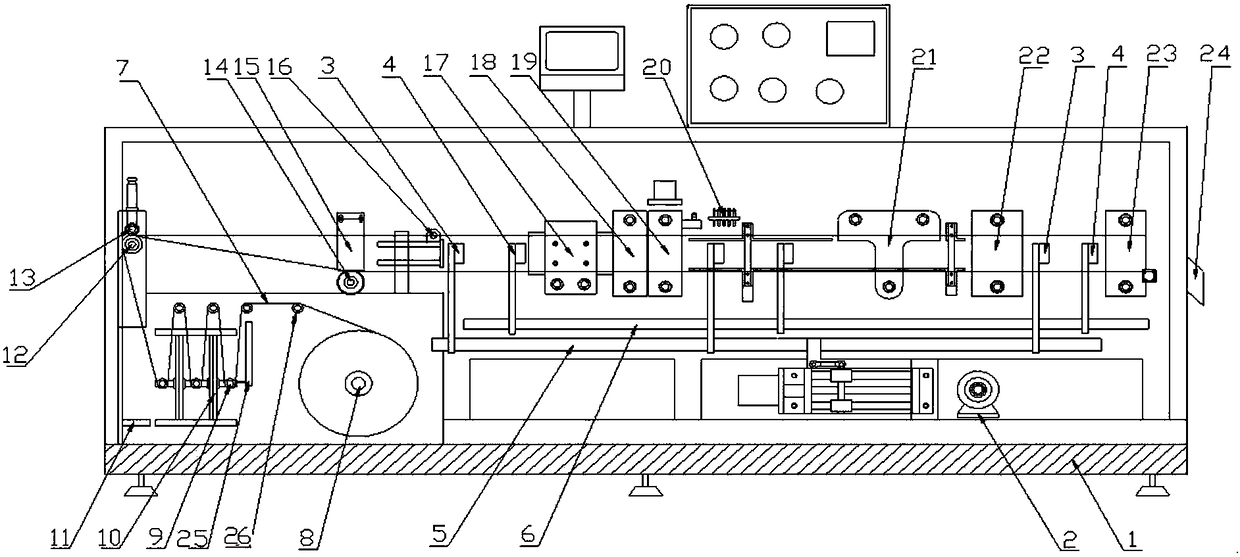

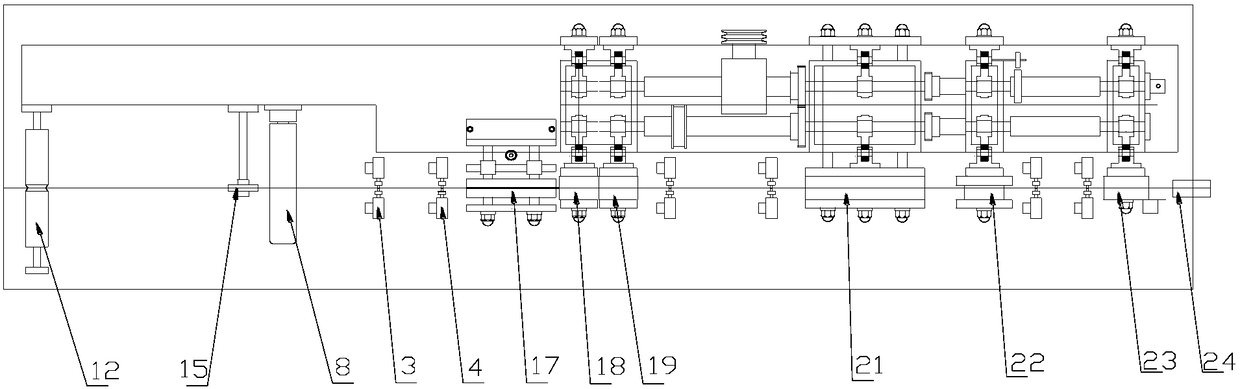

[0022] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0023] Such as figure 1 As shown, the plastic bottle automatic forming liquid filling machine of the present invention comprises a frame 1, on which a plastic sheet film transmission unit, a heating unit, a molding unit 19, a filling unit 20, a sealing unit 21, Punching trimming unit 22 , indentation cutting unit 23 , and discharge port 24 . Frame 1 front is provided with openable cabinet door, for the convenience of real-time understanding of production status, frame 1 cabinet door and frame 1 upper surface material are preferably transparent materials such as transparent plexiglass.

[0024] Wherein, the plastic sheet film conveying unit includes a feeding roller 8 and a plastic sheet film dividing assembly. The feed roller 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com