Continuous instantaneous exposure photocuring printer provided with anti-sticking resistance-reducing nano-structured tank bottom

A nanostructure and printer technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as large interface adhesion, parts processing failure, peeling failure, etc., to reduce adhesion, resin The effect of reduced flow resistance, continuous and fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

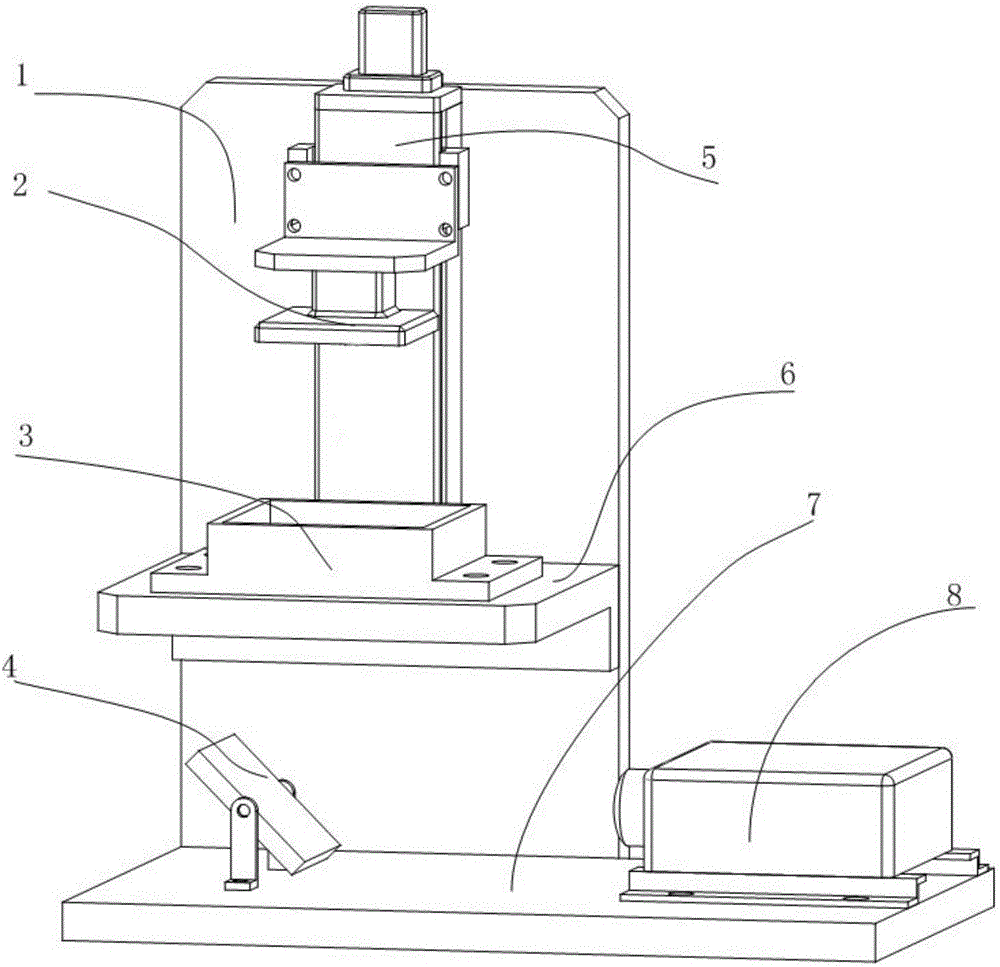

[0022] In one embodiment, the printer includes: a curing light source, a micromirror array, a resin tank, a pallet for carrying printed parts, a side support plate, a feeding device, and a base;

[0023] The base is used to fix the curing light source, the micromirror array and the side support plate; the resin tank and the feed device are fixed on the side support plate; the supporting plate carrying the printed parts is connected to the feed device;

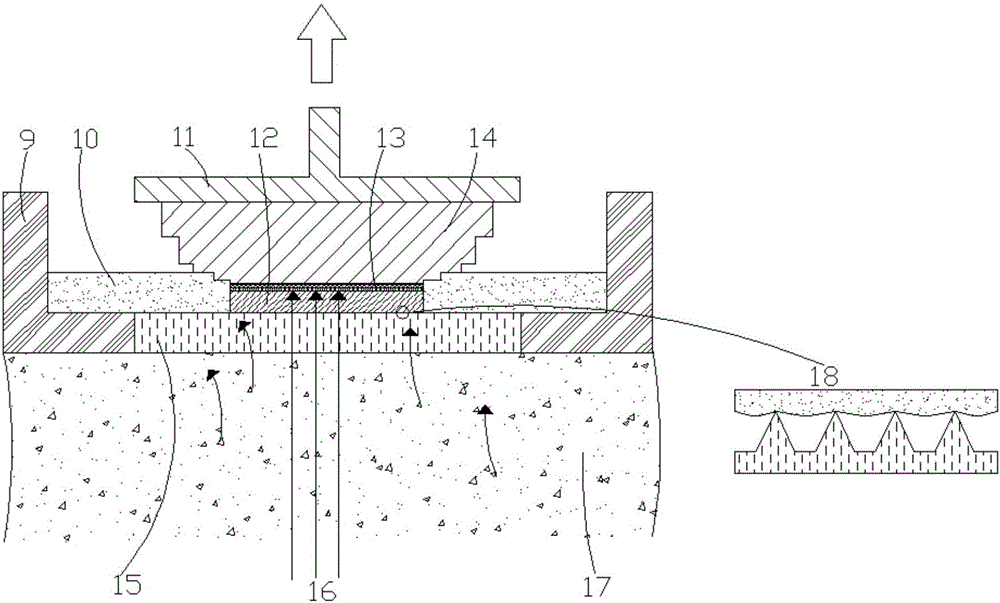

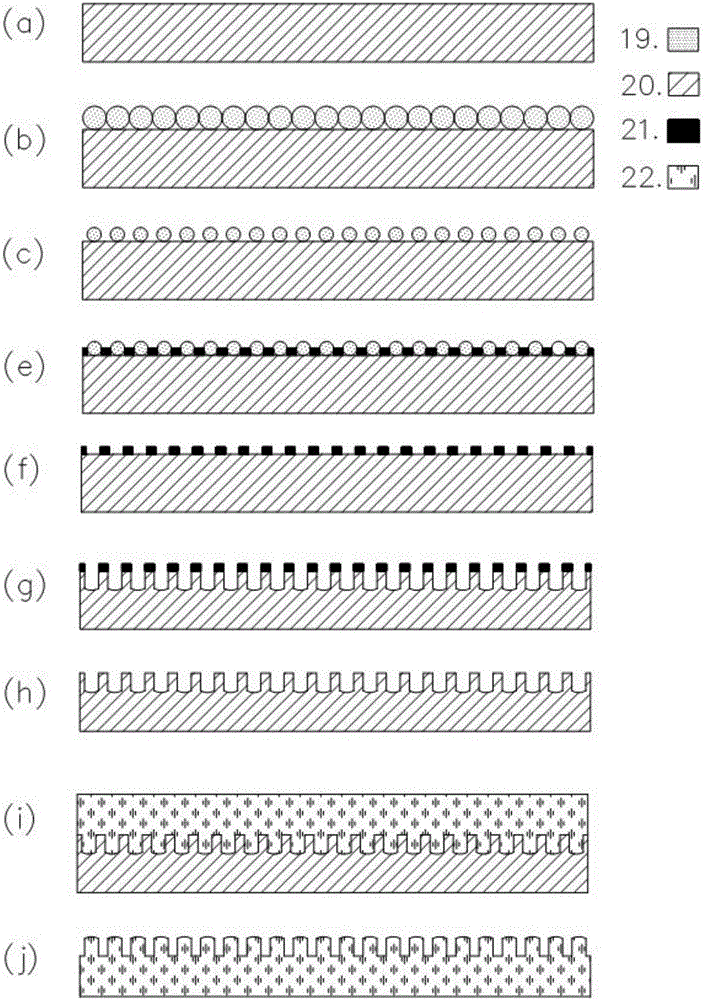

[0024] The surface of the resin tank is made of air-permeable and liquid-repellent material, and the surface of the resin tank has a quasi-periodic nanostructure.

[0025] In this embodiment, the breathable and lyophobic material used on the surface of the resin tank has good permeability to oxygen and is lyophobic. The resin tank is made of breathable material, and the permeable oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com