Multi-functional printing production line

A production line and multi-functional technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as manual repair welding, many welding defects, and waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following further describes the present invention based on the drawings and specific embodiments, but the implementation of the present invention is not limited thereto.

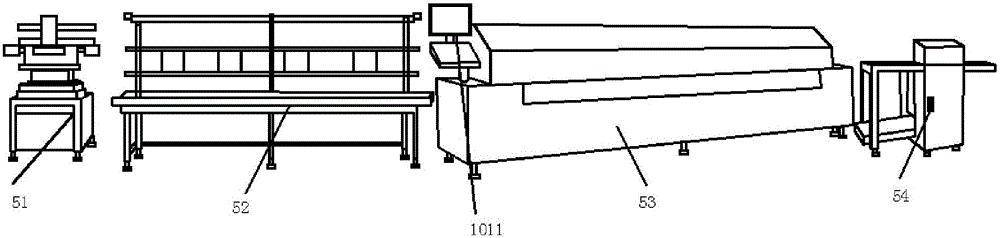

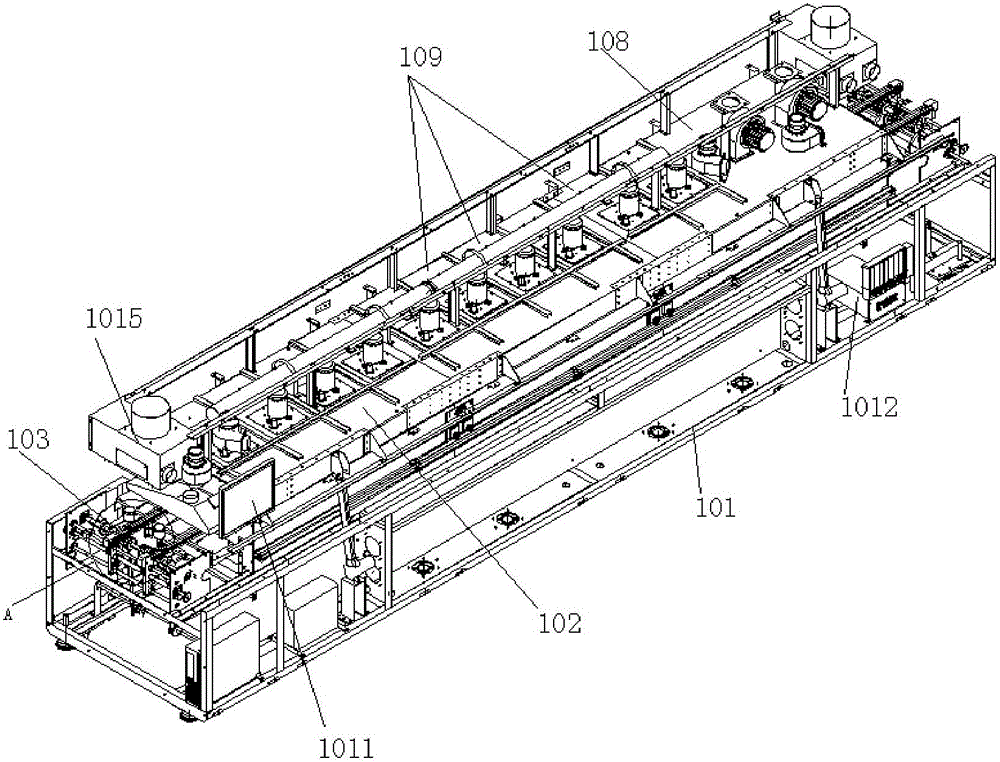

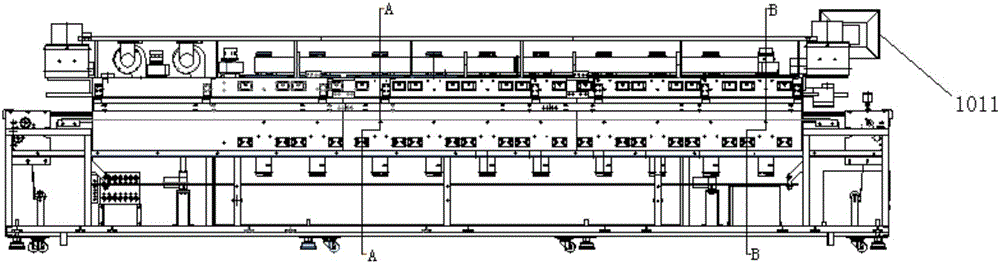

[0052] Such as figure 1 As shown, a multifunctional printing production line includes a tin filling machine 51, a plug-in conveying line 52, a reflow soldering machine 53, and a blanking machine 54 arranged in sequence. The product passes through the plug-in conveying line 52 after filling tin from the tin filling machine 51. , The product on the plug-in conveyor line 2 is manually inserted into the product, and the product after the component is inserted is transported to the reflow soldering machine 53, through the reflow soldering machine 53 for melting and welding, and the product is neatly stacked by the blanking machine 54 Put down the material for collection, the tin filling machine 51 is equipped with a replaceable steel mesh structure and a scraper head device, and the reflow soldering machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com