Catapult of flywheel-type high-speed unmanned aerial vehicle

A catapult and flywheel-type technology, applied in the field of UAV launching devices, can solve the problems of low launch speed, long acceleration distance, complex and huge system, etc., and achieve less intermediate transfer process, short acceleration distance and high launch speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

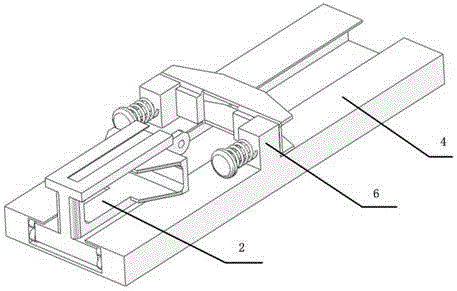

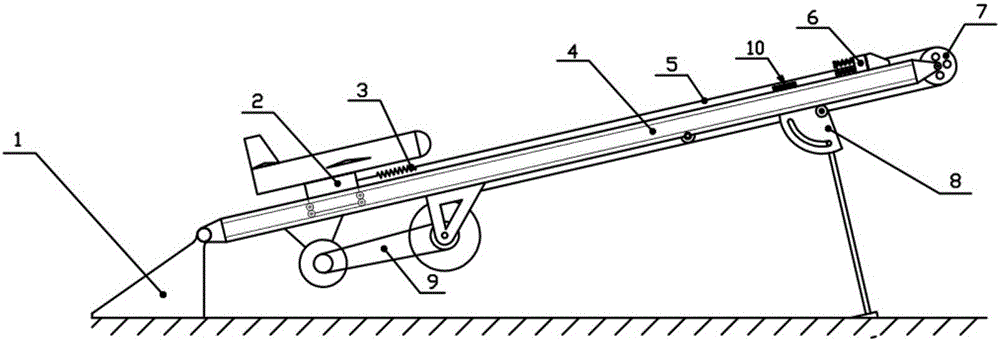

[0017] Referring to the accompanying drawings, a flywheel-type high-speed unmanned aerial vehicle catapult includes: a support seat 1, a tackle 2, a frame body 4, a traction cable 5, a blocking device 6, a guide wheel 7, a bracket 8, a power system 9 and a position sensor 10;

[0018] The support seat 1 and the bracket 8 are used to support the frame body 4, so that the frame body 4 is inclined upward at a set angle;

[0019] The tackle 2 moves on the slideway of the frame body 4, on which a high-speed drone is connected, and the head of the tackle 2 is provided with a buffer spring 3;

[0020] The power system 9 provides traction power to the tackle 2 through the traction cable 5 bypassing the guide wheel 7;

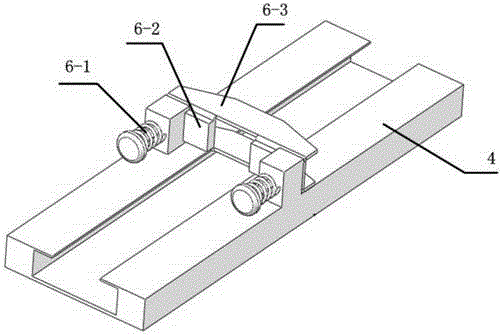

[0021] The position sensor 10 and the blocking device 6 are installed on the frame body 4, and when the position sensor 10 senses that the tackle 2 passes, it sends a stop signal to the power system 9; the blocking device 6 is used to block the movement of the tackle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com