Method for producing organic fertilizer by straw decomposition

A technology for decomposing straws and organic fertilizers, applied in the fields of organic fertilizers, fertilization methods, nitrogen fertilizers, etc., can solve the problems of large soil pores, difficult decomposition and transformation of straws, and competition for nitrogen, so as to avoid environmental pollution, reduce economic investment, increase The effect of nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

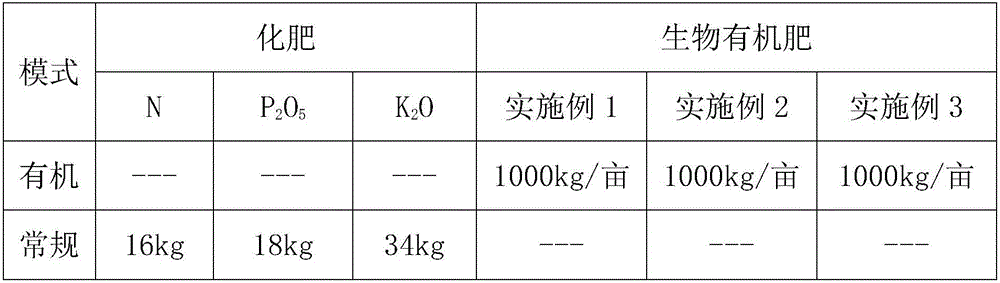

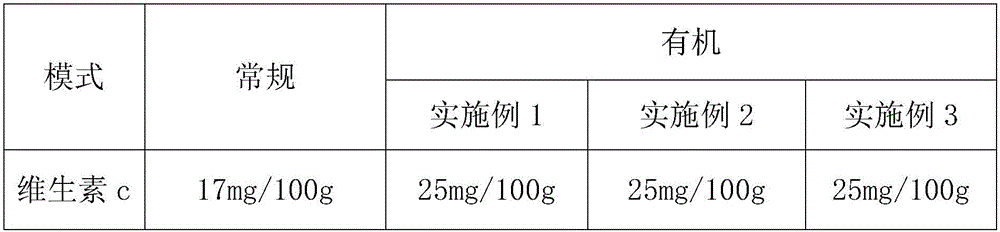

Embodiment 1

[0033] A method for producing organic fertilizer by decomposing straw, the steps of which are as follows: (1) pulverize the straw with a pulverizer, return the pulverized straw to the pulverizer for further pulverization, make it pulverized evenly, and obtain straw powder; The straw mentioned above is one or more of rice straw, corn straw, potato straw and rapeseed straw; corn straw is preferred in this embodiment. (2) In parts by weight, mix 130 parts of straw minced powder and 100 parts of humic acid to obtain a straw decomposed base material, and carry out composting fermentation on the straw decomposed base material, and the fermentation time is 40 days; Provide sufficient oxygen for aerobic fermentation. (3) Add amino acid, bacterial bag and animal fur to the decomposed straw base material after step (2), stir evenly and enter the pulverizer for pulverization to obtain decomposed organic fertilizer base material, each of which is decomposed organic fertilizer The composi...

Embodiment 2

[0035]A method for producing organic fertilizer by decomposing straw, the steps of which are as follows: (1) pulverize the straw with a pulverizer, return the pulverized straw to the pulverizer for further pulverization, make it pulverized evenly, and obtain straw powder; The straw mentioned above is one or more of rice straw, corn straw, potato straw and rapeseed straw; corn straw is preferred in this embodiment. (2) In parts by weight, mix 170 parts of straw minced powder and 140 parts of humic acid to obtain a straw decomposed base material, and carry out composting fermentation of the straw decomposed base material for 50 days; Provide sufficient oxygen for aerobic fermentation. (3) Add amino acid, bacterial bag and animal fur to the decomposed straw base material after step (2), stir evenly and enter the pulverizer for pulverization to obtain decomposed organic fertilizer base material, each of which is decomposed organic fertilizer The composition share ratio is: 170 pa...

Embodiment 3

[0037] A method for producing organic fertilizer by decomposing straw, the steps of which are as follows: (1) pulverize the straw with a pulverizer, return the pulverized straw to the pulverizer for further pulverization, make it pulverized evenly, and obtain straw powder; The straw mentioned above is one or more of rice straw, corn straw, potato straw and rapeseed straw; corn straw is preferred in this embodiment. (2) In parts by weight, mix 150 parts of straw minced powder and 120 parts of humic acid to obtain a straw decomposed base material, and carry out composting fermentation of the straw decomposed base material, and the fermentation time is 45 days; turn the pile every 13 days, Provide sufficient oxygen for aerobic fermentation. (3) Add amino acid, bacterial bag and animal fur to the decomposed straw base material after step (2), stir evenly and enter the pulverizer for pulverization to obtain decomposed organic fertilizer base material, each of which is decomposed or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com