Method and system for recycling sec-butyl acetate in sec-butyl acetate preparation by-product heavy hydrocarbons having carbon number of 12 or more

A technology of sec-butyl acetate and by-products, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. Complete and other problems to achieve the effect of reducing temperature, reducing energy consumption, and changing separation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

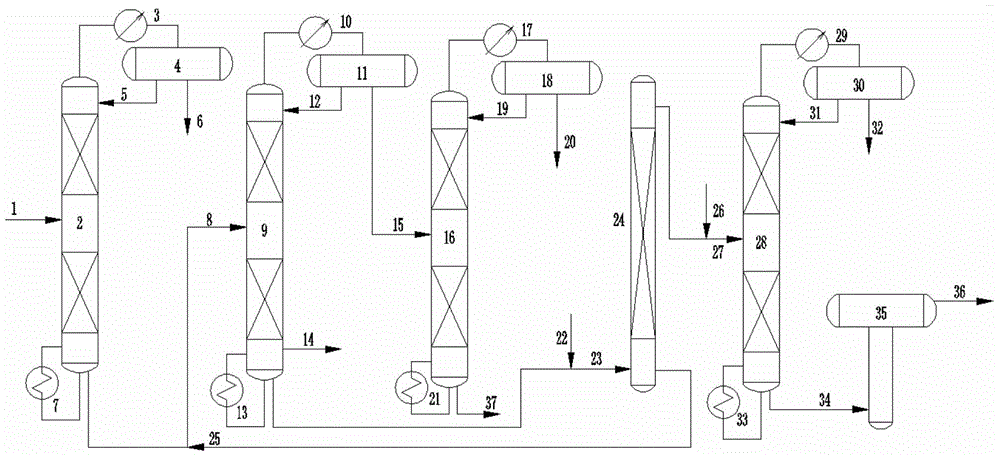

[0065] The by-product heavy hydrocarbons above C12 produced in the process of reacting acetic acid with C4 to prepare sec-butyl acetate are sent to the sec-butyl acetate recovery tower with a flow rate of 5t / h. The content is 15.28wt%, the content of C12~C16 hydrocarbons is 84.15wt%, and the content of water is 0.57wt%. , the reflux ratio is 0.2, the number of theoretical plates is 15, add entrainer water, the mass flow rate of water is 1.5t / h, through azeotropic rectification, sec-butyl acetate and water are azeotropically distilled from the top of the tower, through After condensation, the oil and water are separated, the upper oil phase enters the refining tower for further separation, and the lower water phase returns to the tower through the water feeding line for recycling. C12~C16 hydrocarbons and part of the water fall into the tower kettle, are drawn out through the side line and enter the heavy hydrocarbon intermediate tank, and after cooling and stratification, heav...

Embodiment 2

[0067]The by-product heavy hydrocarbons above C12 produced in the process of reacting acetic acid with C4 to prepare sec-butyl acetate are sent to the sec-butyl acetate recovery tower with a flow rate of 5t / h. The content is 88.12wt%, the content of C12~C16 hydrocarbons is 10.97wt%, and the content of water is 0.91wt%. , the reflux ratio is 0.25, the number of theoretical plates is 50, add entrainer water, the mass flow rate of water is 1.2t / h, through azeotropic rectification, sec-butyl acetate and water are azeotropically distilled from the top of the tower, through After condensation, the oil and water are separated, the upper oil phase enters the refining tower for further separation, and the lower water phase returns to the tower through the water feeding line for recycling. C12~C16 hydrocarbons and part of the water fall into the tower kettle, are drawn out through the side line and enter the heavy hydrocarbon intermediate tank, and after cooling and stratification, heav...

Embodiment 3

[0069] The by-product heavy hydrocarbons above C12 produced in the process of reacting acetic acid with C4 to prepare sec-butyl acetate are sent to the sec-butyl acetate recovery tower with a flow rate of 5t / h. Content is 21.25wt%, and the content of C12~C16 hydrocarbon is 78.34wt%, and the content of water is 0.34wt%, and the content of C8 light hydrocarbon is 0.07wt%, and the pressure of sec-butyl acetate recovery tower is normal pressure, and tower top temperature is 90°C, the temperature at the bottom of the tower is 102°C, the reflux ratio is 0.3, and the number of theoretical plates is 45. Add entrainer water, and the mass flow rate of water is 1.9t / h. Through azeotropic distillation, sec-butyl acetate and The azeotrope of water, C8 light hydrocarbons and water is distilled from the top of the tower, oil and water are separated after condensation, the upper oil phase enters the refining tower for further separation, and the lower water phase returns to the tower through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com