A high temperature resistant profile control agent and preparation method thereof

A profile control agent, high temperature resistant technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of uneven steam suction profile and interwell steam channeling in steam flooding reservoirs, and achieve strong low temperature curing ability , Fast curing speed, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

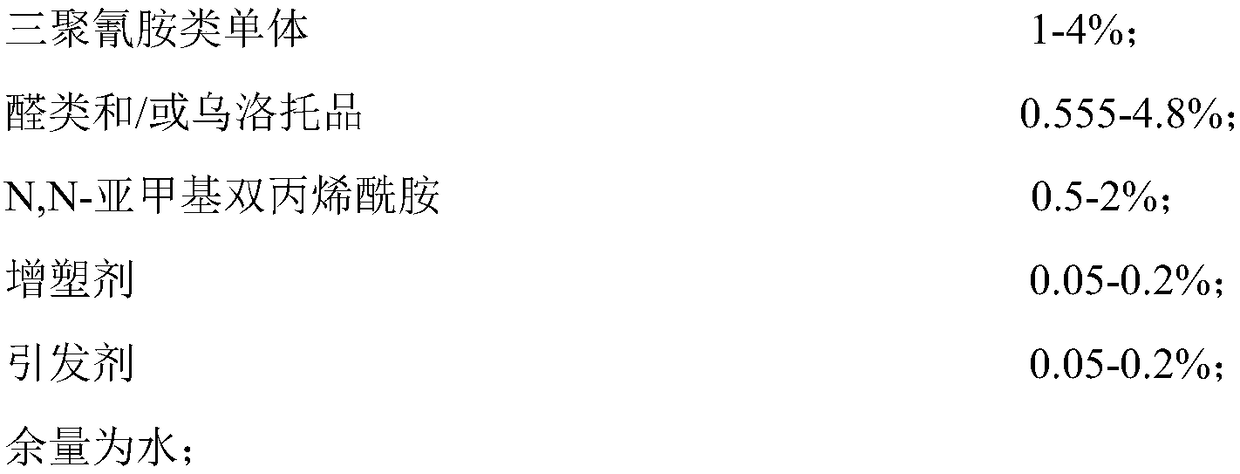

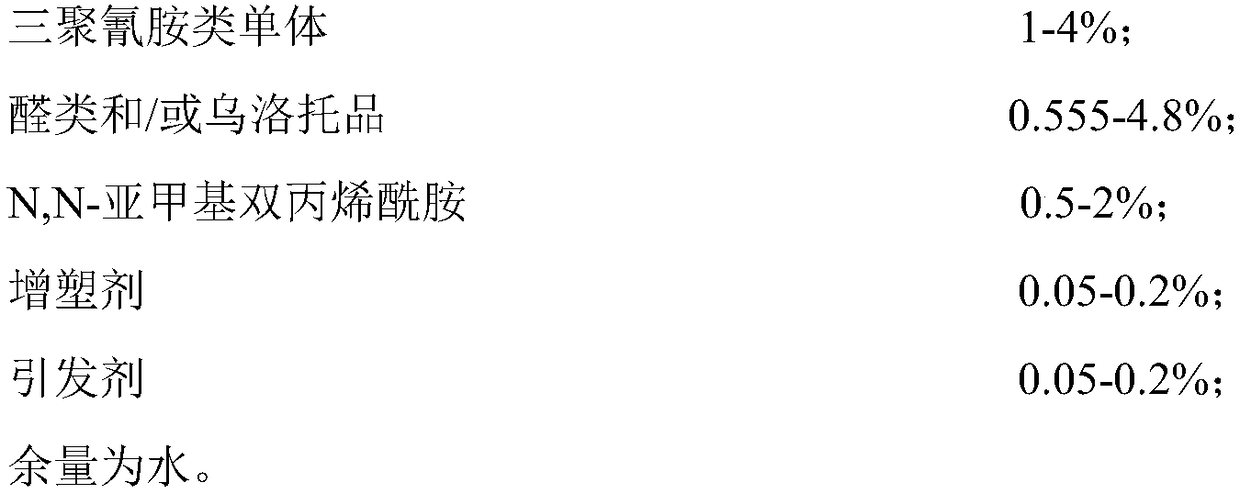

[0033] This embodiment provides a high temperature resistant profile control agent, in terms of mass percentage, the raw material composition of the profile control agent is:

[0034] Melamine: 4%;

[0035] Formaldehyde solution: 12%;

[0036] N,N-methylenebisacrylamide: 2%;

[0037] Diallyl phthalate: 0.2%;

[0038] Sodium persulfate: 0.2%;

[0039] The balance is sewage from Liaohe Oilfield, and the temperature is 40°C;

[0040] The mass percentage concentration of the above-mentioned formaldehyde solution is 37-40%.

[0041] The specific preparation process of the profile control agent is:

[0042] (1) Add melamine and formaldehyde solution to oilfield sewage at 40°C in sequence, stir and dissolve fully for 20-30min, and the stirring speed is 50-200r / min;

[0043] (2) Add N,N-methylenebisacrylamide, plasticizer, and initiator to the above solution in sequence, and continue stirring for 30 minutes to obtain a high-temperature-resistant profile control agent.

Embodiment 2

[0045] This embodiment provides a high temperature resistant profile control agent, in terms of mass percentage, the raw material composition of the profile control agent is:

[0046] Benzomelamine: 1%;

[0047] Hexatropine solution: 1.5%;

[0048] N,N-Methylenebisacrylamide: 0.5%;

[0049] Diallyl isophthalate: 0.05%;

[0050] Potassium persulfate: 0.05%;

[0051] The balance is sewage from Liaohe Oilfield;

[0052] The mass percentage concentration of the above-mentioned urotropine solution is 37-40%.

[0053] The specific preparation process of the profile control agent is:

[0054] (1) Add melamine and urotropine solution sequentially to the oilfield sewage above 40°C, fully stir and dissolve for 20-30min, and the stirring speed is 50-200r / min;

[0055] (2) Adding N,N-methylenebisacrylamide, plasticizer and initiator successively to the above solution;

[0056] (3) After continuing to stir for 30 minutes, a high temperature resistant profile control agent is obtaine...

Embodiment 3

[0062] This embodiment provides a high temperature resistant profile control agent, in terms of mass percentage, the raw material composition of the profile control agent is:

[0063] Melamine: 2%,

[0064] Hexatropine solution: 6%,

[0065] N,N-Methylenebisacrylamide: 1%,

[0066] Diallyl phthalate: 0.1%,

[0067] Potassium persulfate: 0.1%,

[0068] The balance is sewage from Liaohe Oilfield;

[0069] The mass percentage concentration of the above-mentioned urotropine solution is 37-40%.

[0070] The specific preparation process of the profile control agent is:

[0071] (1) Add melamine and urotropine solution sequentially to the oilfield sewage above 40°C, fully stir and dissolve for 20-30min, and the stirring speed is 50-200r / min;

[0072] (2) Adding N,N-methylenebisacrylamide, plasticizer and initiator successively to the above solution;

[0073] (3) After continuing to stir for 30 minutes, a high temperature resistant profile control agent is obtained.

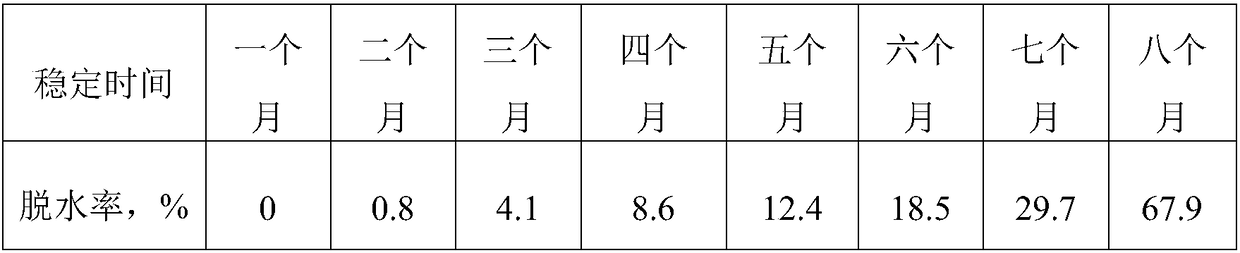

[0074] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com