A kind of high-temperature high-salt oil reservoir anti-CO2 gas channeling plugging agent and preparation method thereof

A high-temperature, high-salt, plugging agent technology, applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems such as insufficient plugging performance, achieve low damage rate, prolong in-situ gelation Time, low filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

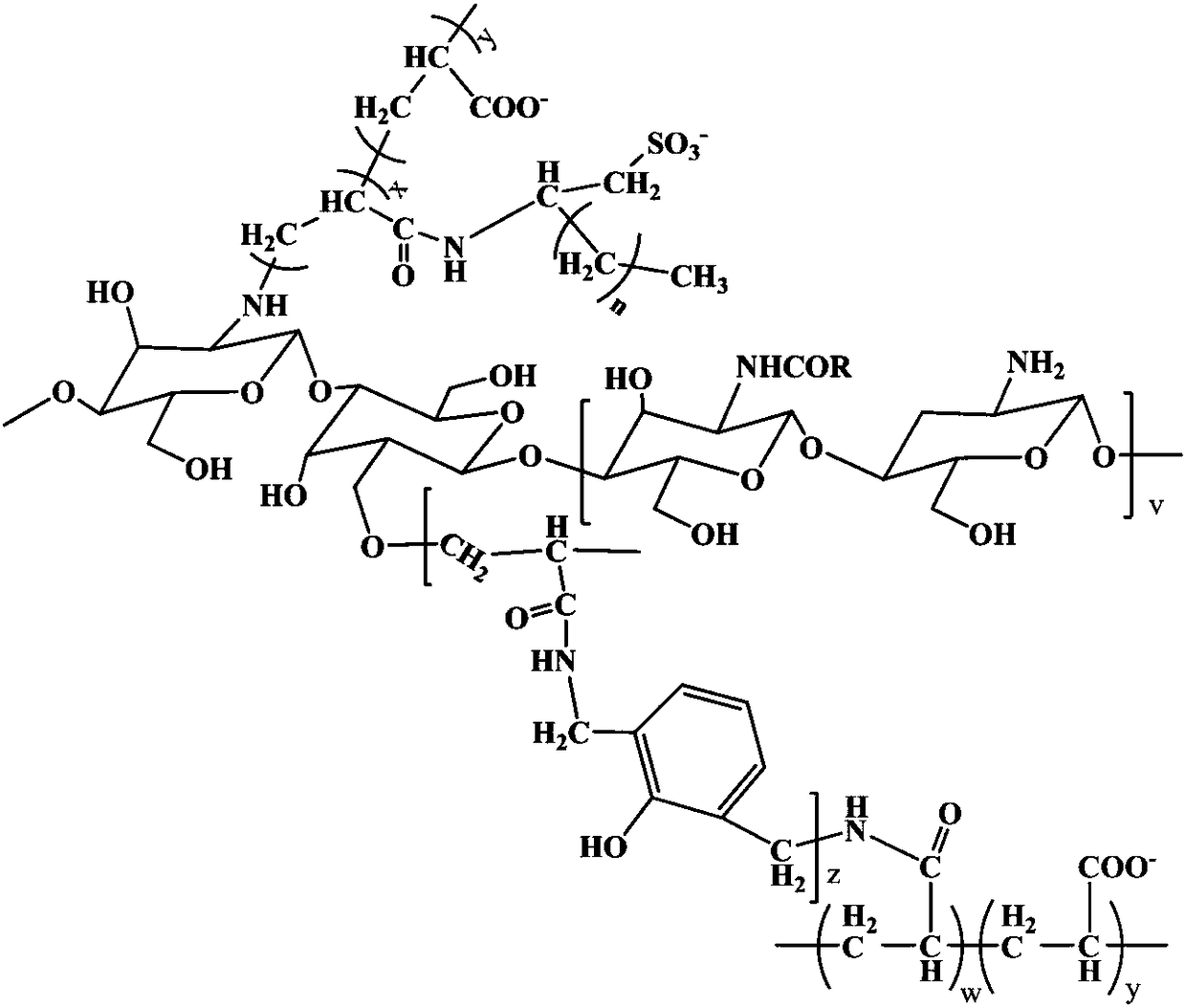

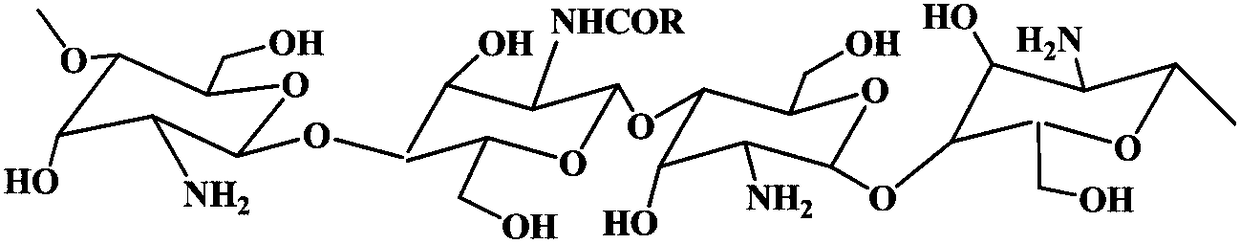

Method used

Image

Examples

Embodiment 1

[0036] Carboxymethyl chitosan 1%, AM 3.5% ~ 6.2%, AA 0.25%, AMC 12 S or AMC 14 S 0.05%, AIBA 0.008%, phenolic crosslinking agent 0.8%, and the rest is water. The gelation time is 48-84h, and the final gelation is I~J grade.

[0037] Table 2 Anti-CO 2 Channeling agent embodiment 1 gelling situation

[0038] AM (%)

Embodiment 2

[0040] Carboxyethyl chitosan 2%, AM 3.5%-6.2%, AA 1%, N-vinylpyrrolidone 0.06%, AIBA 0.01%, phenolic cross-linking agent 1.0%, and the rest is water. The gelation time is 48-72h, and the final gelation is G~J grade.

[0041] Table 3 Anti-CO 2 Channeling agent embodiment 2 gelling situation

[0042] AM (%)

Embodiment 3

[0044] Carboxyethyl chitosan 1.5%, AM 4-6%, AA 0.75%, 2-acrylamido-2-methylpropene sulfonate sodium 0.1%, (NH 4 ) 2 S 2 o 8 -NaHSO 3 0.012%, 1.2% phenolic crosslinking agent, and the rest is water. The gelation time is 48-60h, and the final gelation is grade G-I.

[0045] Table 4 Anti-CO 2 Channeling agent embodiment 3 gelling situation

[0046] AM (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com